Iron wire

Soft iron wire is useful for many tasks, and is most often used for various types of fixing.

Wire sizes

Smallest

- Sandwich bag closer ties are thin 0.3 - 0.4mm iron wire in paper or plastic tape, which makes it easier to handle.

- For very light temporary fixing

- Twisted ties tend to come undone when force is applied

- Widely used for securing plants to walls & stakes

- Limited DIY use

0.5mm

- Can be treated like super string. It does what string does, but also will hold in any position its put in, its far stronger, it twists to make knots, can be shaped for poking, etc.

- Easily cut and worked by hand

1mm

- Thin iron wire useful for light duty fixing

- Easily cut & twisted

- Soft & very easily bent with bare hands

- High flexibility means it can be pulled to shape by the final twisting

1.6mm

- Tough fairly rigid iron wire where more strength is needed.

- Easier to handle than 2mm.

- Straighten before use, can't easily be pulled straight

2mm

Rigid iron wire. Rigid enough for making various small metalware items

3mm

- Useful where great rigidity is required.

- Hard to work

4mm+

4mm and up is rarely used as wire in DIY, and is difficult to work. Its mainly used as parts of manufactured goods.

Finishes

- Most iron wire is galvanised.

- PVC coated is also available, usually in green for garden use. The extra bulk makes the wire slightly easier to handle, and tied wire unwinds a little easier.

- 3mm wire from coathangers is usually varnished.

Specialist finishes are also available for non-diy use:

- gold finish from haberdashers

- paper finish from florists' suppliers

- bonsai wire

Working

Cutting

Cutting iron wire with pliers & wire cutters tends to ruin the cutters quickly. Small or miniature bolt croppers or fencing pliers are suitable. Aviation tinsnips work well for small wire, and can just about manage 2mm.

If stuck with no suitable tool, iron wire may be cut by making a shallow groove in one side and bending a few times. A groove may be made with a file, hacksaw, blunt wire cutters, masonry chisel, axe, grinder, sharpened flat prybar, etc.

Bending

Sizes above 1mm often need to be pre-shaped, as twisting doesn't pull them to shape. 2 pairs of pliers are used to shape iron wire. With larger sizes, water pump pliers are easier.

Fixing

Iron wire is twisted with pliers to fix it. It may also be stapled to timber with fencing staples.

1mm and below may be given added resistance to coming undone by twisting once, hooking the ends under the main wire loop, then twisting again.

To avoid sharp ends being exposed, the twisted section may be folded over on itself so the cut ends press against the item being fixed. Where the wire ends will be subject to handling, a fine file (in good condition) can take the sharpness off the wire end in a few strokes. For the best finish file the end flat then a single pass around the edge removes the pointedness of the edges/corners.

Uses

Tie fixing

Wire is wrapped round the items to be fixed, and the ends are twisted together with pliers until tight. Overtightening would snap the wire.

Hoses

Iron wire is sometimes used to fix hoses. The result is not as strong as purpose made flat section fixings, but is adequate for many uses, and costs next to nothing.

2 turns round the hose should be used to avoid an unpressured spot where the wire ends leave the hose. Don't overtighten or it cuts into the hose. 1.6mm is good, or 1mm for very small hoses (eg 1/4")

Fencing

A large amount of iron wire is used for fencing. Traditional wire fencing is frugal fencing, just 2 or 3 horizontal runs of wire, tensioned, between posts. Fencing pliers are a single tool able to tension, twist and cut iron wire, and hammer in staples for fixing it.

Cable threading

Duct tape iron wire to the end of cable or string, and it can be threaded through various restricted spaces. 2mm is good for this, or 1.6mm for short distances.

Making a small diameter ring on the nose of the threading rod enables it to glide over rough surfaces. Close the ring rather than leaving it as a U shape to minimise the risk of it catching and not coming back out.

Small metalwares

Numerous small metal objects can be made from rigid iron wire. Some examples are corner braces, clips, hooks, tool stands, simple hinges & door catches, and many other items, both ad-hoc and permanent.

Bolts

Iron wire can be used as bolt substitutes with a lower maximum load.

Shelf hanging

Iron wire can be used for lightweight or temporary shelf supports. Shelf height can be raised by twisting the wire tail under the shelf with pliers.

Picture hanging

1mm wire is good for hanging pictures upto a couple of feet in size. Where long enough wire will be used for it to be visible, brass wire is preferred for appearance.

Other uses

- Low cost light mortar reinforcement (use only galvanised) (small tight loops create anchoring points)

- Retrieving things in inaccessible spaces

- Restraint wires to prevent damage in case of primary fixing failure (eg wall mounted tvs, outdoor structures etc)

- Numerous temporary repairs

- Catenary wires (short only, minimum cost)

- Fixing various car parts in place

- Making miniature tools for special purposes

Knots

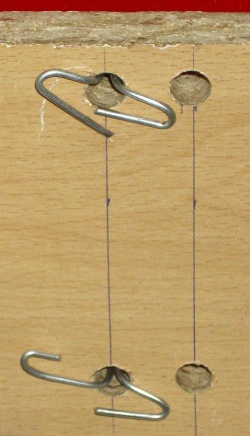

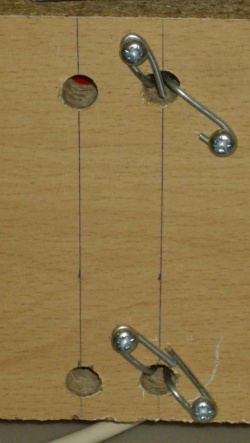

From the left:

- Basic twist tied 0.5mm

- Ends folded down to minimise minor injury risk. 1mm PVC coated.

- Twisted, looped, twisted 0.5mm. Prevents it being pulled undone.

- Hose knot (2 turns) ensures pressure all round. 1.6mm

- Basic twist tied 2mm. Ends filed for safety.

Beautification

Appearance matters where items made will be visible in use.

Straightening the wire properly before use, removing all kinks, is essential. Failure to take the time to do this properly will make a good final appearance impossible. This is simply a matter of unbending all bends, however slight, until completely straight.

Where bent, nice even smooth curves can be achieved by bending the wire around a round object, and pressing on it to prevent the initial bend deforming the wire outside of the intended bend zone.

Cut ends should be filed flat. This is quite quick to do.

Safety

- Cut ends waggling about during work can poke and injure eyes.

- Iron wire in unseen spaces can come into contact with live electrical connections. Gloves can reduce the risk.

- Coils of wire are trip hazards.

- Cutting often requires high forces. Keep fingers well clear, cutters slip easily.

- Sharp cut ends protruding from finished fixings present a risk of minor injury.

Cut ends are usually bent out of the way to prevent injury. If necessary the sharpness can be filed off with a few strokes of a file.

Suppliers

- Hardware shops, DIY sheds, builder's merchants and garden centres sell iron wire.

- http://www.wires.co.uk

- http://www.mutr.co.uk

- http://www.ormiston-wire.co.uk/

Between them these suppliers provide a vast array of wire types, far beyond the iron and copper used for DIY. These include silver wire, stainless steel, copper, enamelled copper, resistance wire, coloured enamelled copper, pre-knitted wire tube, aluminium, gold, brass, litz, bronze, controlled expansion alloys, dcc (double cotton covered copper), silk covered copper, heater cable, iron wire (bare, black, galv), kynar, constantan, eureka, manganin, nichrome, nickel, molybdenum, ptfe covered, silicone covered, solder, silver solder, square wire, tungsten, zeranin (precision resistance alloy), non-tarnish silver, multitone wires, bouillon, spiralled & tinsel wires, purl, memory wire, zinc, etc.

If you don't have the right wire size in stock, sometimes one can improvise.

- Food bag closure ties use sub-millimetre iron wire

- Wire coathangers are usually around 3mm diameter.

- Paper clips are spring steel, making them tough and springy. They can be re-worked to make miniature items, including springs, but are no use for twist tying.

- Copper electrical wire from cables can be used for tie fixing where lower strength is acceptable. T&E cable provides 1.1mm diameter(from 1mm² cable), 1.4mm dia (1.5mm²) and 1.8mm dia (2.5mm²) copper wire.