Napkin holder

Introduction

A quick and easy project, to make a simple napkin holder for the table. This one is constructed from some offcuts of American Black Walnut and Maple to give a good contrast.

Design

The only real design criteria was for something that was light and easy to handle, and that would hold a stack of standard folded 30cm square napkins. This was built on the fly with no real plans. The dimensions being dictated by the size of the folded napkin.

Construction

This was fairly straight forward. Some 6mm (1/4") stock was prepared for the sides, and some 9mm (3/8) inch boards planed up for the base. The the base was glued up from 3 small boards the same height as the sides.

Th back panel was made from some taller maple stock, so that the handle could be cut into it. The profile shape was just sketched out on one side with a flexi curve and then cut on a bandsaw. The offcut was then flipped over and used to mark the other side before that was cut. The ends of the handle hole were drilled with a forstner bit, and the holes joined up with a fretsaw. Finally the inner recess was rasped into a decent shape, and sanded smooth.

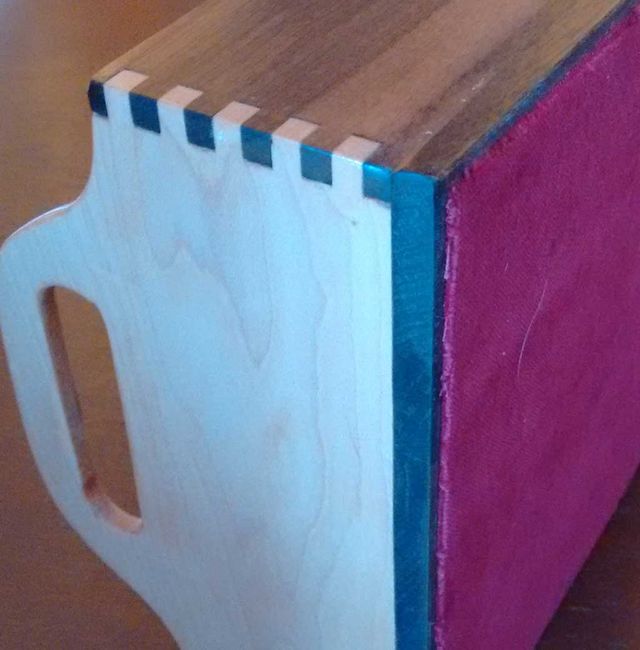

Once all the flat bits were cut and shaped, the finger joints were cut in the same way as described here. Everything was then sanded to 320 grit.

The sides were then glued up, (making sure they were square) and allowed to dry. The base was trimmed to be a 1/8" wider and longer than the sides such that it would leave a very slight reveal at the base. The top edge was given a slight chamfer when sanding.

To allow for wood movement with humidity changes, the top was then glued to the base in only three small areas: in the centre of the back panel, and then the two front corners.

Finishing

Since this needed to be food safe, the finish used was Tongue Oil, applied in around three or four coats (the Walnut needed one more coat than the less absorbent maple). The final finish being achieved by applying Liberon black bison wax with some 0000 wire wool, and then buffing to a soft sheen.

The last step was to glue a square of fabric to the base so that it can't scratch the table. This was done with some spray on contact adhesive applied to both the base and the fabric.