Bearing puller

The following bearing puller is easily made at little cost. It was used to remove and replace washing machine drum bearings, as standard gear pullers were not a suitable pattern.

Click any image to see more detail.

A holesaw is used to cut the discs and holes in wood. The sizes required depend on the machine.

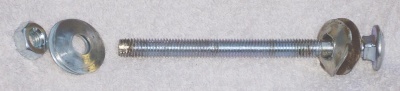

An M12 bolt has 2 flats ground on the non-head end to enable grip with locking pliers. This grip is needed when turning the nuts to achieve high torque. Put 3 nuts on the bolt before grinding, removing them will help clean up the thread. Discard the first nut to come off, it will be damaged. File the damaged thread on the bolt before removing the nuts.

The penny washers were only just strong enough for the job when used in sets of 3. If less are used, the washers deform into a shape liable to split the wood.

In use, the wooden squares aren't used one at a time, this isn't strong enough. A stack of 3 is used to obtain maximum strength, with each square's grain at right angles to its neighbour. In hindsight using plywood would have been a better option.