Cable crimping

Crimping electrical cable joints

(work in progress article - to have photographic demo of crimped cable joints)

Note that this article refers to the jointing of electrical cable in fixed wiring installations, not for extending flexible cables connected to appliances

Acceptable jointing methods

There are various situations where it may become necessary to join an electrical cable, such as when effecting repairs and upgrades to installations. The wiring regulations basically allow for four methods for making cable joints:

- Screw terminal connections

- Joints produced by a compression tool (i.e. Crimped)

- Soldered Joints

- Welded Joints

1) is most commonly used in electrical accessories such as switches and sockets. However this method is only acceptable where the joint will remain accessible for future inspection and maintenance, since screwed terminal connections can become loose over time.

4) Is not an option readily available in many domestic situations. Hence if one needs to make a joint that is robust, and can be safely entombed into a building we are left with 2) & 3).

Why Crimping

Crimping is a quick and reliable method of jointing that is easy to deploy in the field since unlike soldering it does not require time to be spent waiting for a soldering iron to heat up, and poses no burn risk to the operator when working on confined spaces.

Required Tools and Materials

For making reliable crimped joints the correct crimping tool must be used. Adequate crimping tools are of a substantial contruction and include a ratchet tightening mechanism that ensure adequate pressure is applied to the crimp before it is released. A suitable tool is available from most good tool shops and electrical retailers such as [this].

Crimp terminals are available in a number of sizes and two basic types: [Insulated] and [Uninsulated]. Both types can be used, but the procedure is different, and uninsulated crimps require the use of a different crimp tool to insulated ones. For the purposes of this article we will use insulated crimps since these are the more commonly available, and require a little less work to use.

In addition to a crimpt tool you will need a few basic tools like wire cutters, and strippers. You will also need some heatshrink tubing of a size appropriate for the cable to be joined

The wrong tool for the job

Note that the cheap non ratchet crimp tools like this are not suitable:

If you have one of these, save it for stripping wire and cropping small bolts.

The crimping procedure

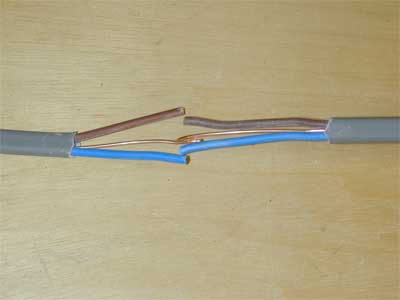

Let's assume we need to repair a section of cable. For this example we will use a section of 2.5mm T&E that has had an unfortunate encounter with a chisel!

Prepare the wire

The first job to do is cut the wire and cut out any damaged section:

Strip the cable back a couple of inches (about 50mm) on each side so that there is room to work.

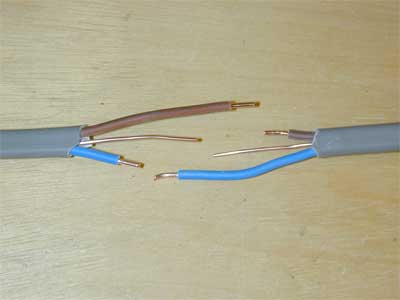

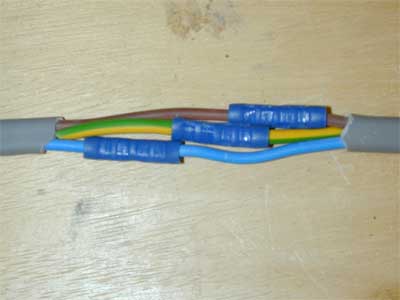

To Reduce the size of the overall crimp, and to make for a neater joint, the lengths of wires can be staggered so that the crimp terminals will not form a bunch:

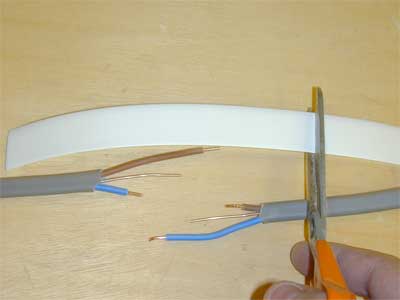

Fit insulation

Before going any further fit the insulation (there is nothing more irritating that completing a nice cable joint only to see the heatshrink tubing laying there with no way of getting it onto the cable (don't ask me how I know!)

Cut some heatshrink that is long enough to not only cover the joint, but also extend an inch of two down the cable. This will make the final joint more moisture resistant. (if waterproofing is really important, then using an adhesive lined heatshrink is a better solution):

Also remember to fit sleeving to the bare earth wire. Slide the heatshrink it up one of the wires until it is out of :

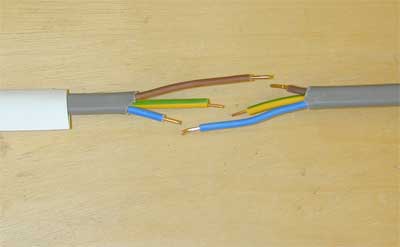

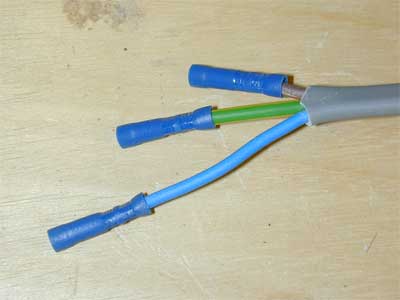

Select suitable crimps

The crimp selected needs to not only match the wire size in question, but also have enough current carrying capacity for the circuit. The Blue crimps used here have the following spec:

- BLUE 32A BUTT SPLICE (100/PACK)

- Area, wire size min:1.04mm²

- Area, wire size max:2.63mm²

- Current rating:27A

- Material, contact:Copper

- Material, insulator:Coloured Vinyl

- Plating, contact:Electro-tinned

- Temp, op. max:85°C

- Temp, op. min:-20°C

- Voltage rating, AC:415V

Crimp

Position the crimp in the jaws of the crimp tool (in the recess for the marked with the same colour as the crimp), and squeeze gently so as to grip the crimp without squashing it:

You should position the crimp so that the active part of the jaws are directly over the metal part of the crimp, leaving the empty part of the plastic insulation sticking out

Insert the wire such that the insulation is tucked inside the shrouded part of the crimp:

Once the crimp is made, you should inspect the crimp to ensure it looks correctly compressed and the wire is still in the correct place with no uninsulated section showing:

Repeat for the other wires in the cable:

Finally complete the crimp to the other cable:

Test

Once the cable is joined, you can test your work. The first test is mechanical, you should not be able to pull a wire free of the crimp even by applying reasonable force.

To test electrically, find where the cable you have repaired connects to the exiting circuit at both ends. Disconnect both and twist the wires at one end together. Now use a multimeter on a low ohms range to measure the resistance between each wire. See the section on Test procedures in the Elctrical Circuit Faults article.

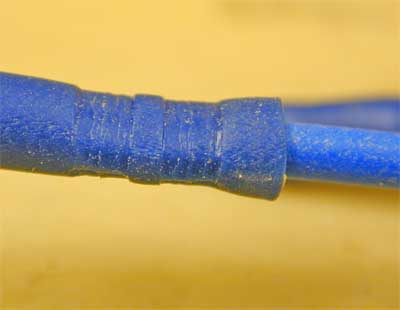

Heatshrink

Last job is to slide the heatshrink over the joint and shrink it:

Heatshrink is best shrunk with a small purpose made hot air gun. If this is not available a gas flame can be used, but it must be played over the joint very quickly and sparingly so as not to scorch it.

--John Rumm 23:17, 16 May 2007 (BST)