Difference between revisions of "Corrosion Inhibitor"

Jump to navigation

Jump to search

(faqloLGwk) |

(cat) |

||

| (5 intermediate revisions by 4 users not shown) | |||

| Line 5: | Line 5: | ||

== Corrosion Inhibitor test == | == Corrosion Inhibitor test == | ||

| − | + | === Test method === | |

| + | |||

| + | # Four bottles were filled each with a similar quantity of water and similar number of (already slightly rusty) nails. | ||

| + | # Inhibitor was added to each of the bottles in the concentrations recommended by their manufacturers. | ||

| + | # The inhibitors used were: | ||

| + | #* Fernox MB-1 | ||

| + | #* Sentinel X100 | ||

| + | #* Purimachos Protex | ||

| + | #* none (control) | ||

| + | # The bottles were then placed together in a warm place (the back of an airing cupboard) | ||

| + | # Six months later the bottles were examined | ||

=== Before === | === Before === | ||

| Line 16: | Line 26: | ||

|} | |} | ||

| − | + | === After === | |

| + | |||

| + | {| | ||

| + | !Fernox | ||

| + | | [[Image:Corrosion_Inhibitor_test_-_Fernox_(2)_040913.jpg]] | ||

| + | | [[Image:Corrosion_Inhibitor_test_-_Fernox_(1)_040913.jpg]] | ||

| + | |- | ||

| + | !Protex | ||

| + | | [[Image:Corrosion_Inhibitor_test_-_Protex_(2)_040913.jpg]] | ||

| + | | [[Image:Corrosion_Inhibitor_test_-_Protex_(1)_040913.jpg]] | ||

| + | |- | ||

| + | !Sentinel | ||

| + | | [[Image:Corrosion_Inhibitor_test_-_Sentinel_(2)_040913.jpg]] | ||

| + | | [[Image:Corrosion_Inhibitor_test_-_Sentinel_(1)_040913.jpg]] | ||

| + | |- | ||

| + | !none | ||

| + | | [[Image:Corrosion_Inhibitor_test_-_none_(2)_040913.jpg]] | ||

| + | | [[Image:Corrosion_Inhibitor_test_-_none_(1)_040913.jpg]] | ||

| + | |} | ||

| + | |||

| + | === Further work === | ||

| + | |||

| + | * Other brands of inhibitor (e.g. Tower, CalChem; seen on the market since this test was carried out) could be tested. | ||

| + | |||

| + | * The test could be repeated with the addition of copper (and perhaps other materials) to the mix to see if these either affect the effectiveness of the inhibitors or (especially in the case of Aluminium etc) suffer corrosion themselves. | ||

| + | |||

| + | * Samples of limescale (e.g. scaled-up pipe or fittings) could be introduced to see whether any inhibitor has actual descaling properties. | ||

| + | |||

| + | * More air could be introduced to the test samples periodically and the samples monitored over a longer period to see how well each inhibitor copes. | ||

| + | |||

| + | * This and similar tests could be repeated by other people. The original tests were carried out by [[user:John Stumbles|John Stumbles]] during 2004. | ||

== External links == | == External links == | ||

| Line 22: | Line 62: | ||

[[Category:Heating]] | [[Category:Heating]] | ||

| − | [[Category:Plumbing]] | + | [[Category:Plumbing]] |

| + | [[Category:Chemicals]] | ||

Latest revision as of 23:21, 12 September 2010

Corrosion Inhibitor is used in the water in Hot Water ("Hydronic") Central Heating systems to protect ferrous components of the system (including steel radiators and cast-iron boiler heat exchangers) from corrosion caused by the action of oxygen dissolved in the water.

Corrosion inhibitors vary in price from about £5 to £15 (for a quantity intended to protect an average domestic installation). The chemistry of corrosion and corrosion-inhibition is, presumably, well known, so one would expect the various different makes of inhibitor to be pretty much equally effective. Unfortunately simple experiment suggests otherwise.

Corrosion Inhibitor test

Test method

- Four bottles were filled each with a similar quantity of water and similar number of (already slightly rusty) nails.

- Inhibitor was added to each of the bottles in the concentrations recommended by their manufacturers.

- The inhibitors used were:

- Fernox MB-1

- Sentinel X100

- Purimachos Protex

- none (control)

- The bottles were then placed together in a warm place (the back of an airing cupboard)

- Six months later the bottles were examined

Before

|

|

|

|

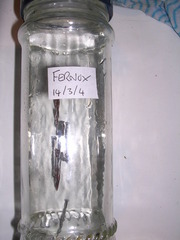

After

| Fernox |

|

|

|---|---|---|

| Protex |

|

|

| Sentinel |

|

|

| none |

|

|

Further work

- Other brands of inhibitor (e.g. Tower, CalChem; seen on the market since this test was carried out) could be tested.

- The test could be repeated with the addition of copper (and perhaps other materials) to the mix to see if these either affect the effectiveness of the inhibitors or (especially in the case of Aluminium etc) suffer corrosion themselves.

- Samples of limescale (e.g. scaled-up pipe or fittings) could be introduced to see whether any inhibitor has actual descaling properties.

- More air could be introduced to the test samples periodically and the samples monitored over a longer period to see how well each inhibitor copes.

- This and similar tests could be repeated by other people. The original tests were carried out by John Stumbles during 2004.

External links

uk.d-i-y thread including discussion of composition of corrosion inhibitors