Die grinder

A Die Grinder is a small high speed rotary power tool. Typically these take an array of tools of upto 1.5" diameter with 1/8" (3.17mm) shank.

Dremel is a popular make of die grinder, and the word Dremel is widely used to mean a die grinder (of any brand).

Tools

Many types of tools are used with these machines.

Drill bit

- 1/8" (3.17mm) bits fit right in

- Other bit sizes must have 1/8" shank

- Its possible to bulk smaller bits upto the right diameter by winding the bit with wire. Don't assume a collet will always hold such arrangements though

- Its also possible to grind 1/8" bits down to get smaller sizes

- If determined its possible to obtain or make other size collets

- Thin drill bits are very weak, sideways force or movement should be carefully avoided

- Don't be tempted to try solid carbide bits in die grinders, in small sizes they are unsuitable and unsafe for handheld tools.

- Larger holes can be drilled in plastic using a different method

Grind stones

- Various shapes, & a few compounds & grades.

- Aluminium oxide is used for most grinding stones, and isn't very good at grinding steel.

- Alox stones come in various light colours.

- Carbide stones are good for steel. These are dark grey, and several times the price of alox.

- Use depends on the material and shape of the bit

Drilling with grind stone

Plastics can be drilled with a pointed cylindrical alox grind stone.

- Drilling occurs by both abrasion & melting

- Speed of cut is good once the stone warms up.

- No risk of cracking

- 1/4" holes drill easily & quickly

- Withdraw the tool without delay once it penetrates

- Makes a mess of the stone

Spiral saw

- 1/8" spiral saw bits can be used in die grinders

- Sideways cutting with a thin weak bit isn't the best combination

- Their uses are limited

Diamond coated engraving bits

- For engraving glass

- Also security marks hard surfaces

- Postcode and often house number are the usual info engraved

- Assorted shapes

Metal wire wheel

- For removing rust, corrosion, scale & paint

- very effective

- Angle grinder wire wheel is much quicker for most work

- Can cause rust staining if used on concrete

- Can also raise 3d grain in wood eg for moulds.

Metal wire pencil brush

- Uses as for wire wheel

- Much less powerful

- More able to get into small spaces and corners

Metal wire cup wheel

- Uses as for wire wheel

- Less powerful

- More able to get into corners etc

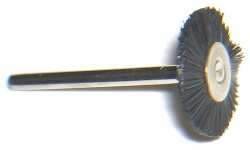

Nylon brush wheel

- Cleaning

- Removal of soft materials

- Removal of loose paint

- Plastic bristles mean it won't damage a much wider range of workpiece materials compared to steel wire wheels

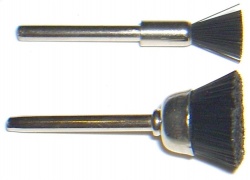

Nylon pencil brush

- Uses as for nylon brush wheel

- Much less powerful

- More able to get into small spaces and corners

Nylon cup brush wheel

- Uses as for nylon brush wheel

- Less powerful

- More able to get into corners

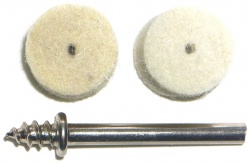

Felt polishing pads

- Polishing metal, plastics,

- Use with polishing compound

- Can also be used to create the circular swirl pattern finish sometimes seen on metalwork

Screw mandrel

- These hold felt polishing pads

- The screw thread tip just screws into the felt pad

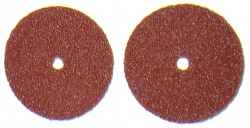

Cutting discs

- The discs are very weak and break very readily. Expect to use a few even for a small job

- Take care to hold the grinder very steady, or disc will break impracticably quickly

- Protective eyewear are best with these usually non-reinforced discs.

- Reinforced cutting discs do exist too

- Slow cutting compared to an angle grinder

- The very narrow kerf of a fraction of a mm is occasionally useful

- Half worn discs can be used for access into very tight places

Sanding drum

- Usually alox grit belts

- Loosen the end screw to release the belt

Rasps

- High speed coarse cutters

- Fast shaping of soft metals, plastics, wood etc

- Don't try to use on high strength materials such as steel or concrete

Sanding discs

- Sandpaper discs are used with a flexible backing pad.

- Typically weak and fine grained, making progress slow

- Not really suitable for stock removal sanding

Flap wheel

- Sanding flaps

- For sanding non-flat surfaces

Tool Maintenance

Grinding stones can clog with metal. This can be removed either by a wirebrush, a coarse abrasive or a spiked wheel.

When grinding soft metals such as aluminium and copper, clogging can be a real problem. Rubbing the disc or stone firmly with chalk first may reduce the clogging to some extent.

Performance

Linear speed of a 1" 30,000 rpm tool is around 2/3 of that of a 4.5" 11,000 rpm angle grinder tool. Also angle grinder discs & brushes are much more robust. So more speed and force are available from an angle grinder than a die grinder.

The prime advantage of die grinders lies in their tiny size, which enables access in restricted spaces, and makes fine work with miniature tools practical.

They are also generally much quieter than angle grinders, which can be an advantage in some situations.

Finally more types of tool are available for die grinders than angle grinders.

Usefulness

How useful are they is a question often asked. Personal experiences follow.

- I rarely use mine, but when I do, nothing else will do.

- I last used one for cutting out some bearings. I don't know any other tool that could have done the job.

- They can be used for cutting pipes in awkward places.

- They de-rust old tools well

- I use mine with a small grinding bit to trim my toenails. The tiny little

grinders the cosmetic firms sell for this purpose are utterly useless, but the Dremel is first rate!

Speed

These tools operate at extremely high rotational speed, and one should check that the tools used are rated for the speed of the machine. There are tools available rated at below typical machine speeds, and these should not be used above their rated speed on safety grounds.

Reducing speed

Some machines can be set to reduced speed to enable lower speed tools to be used, some can't. For machines with no speed control there are some workarounds for speed reduction.

- Running the tool off a 110v transformer gives a max speed of 110/240 x the usual run speed

- When no better alternative is to hand, running a lightbulb in series with the die grinder reduces the voltage and thus speed.

- A multimeter is used to measure the offload voltage and thus calculate max speed. The downside of this arrangement is that as the tool is loaded its speed will reduce at a greater than usual rate as load increases.

- Low voltage tools can be run off a supply of lower voltage to reduce speed.

Speed = voltage/rated voltage x rated speed.

This holds true for both mains and low voltage machines.

See Droppers for more information

Safety

The main risk with these machines is explosion of the tool due to breakage at very high speed.

Speed rating of machine and tool are important, the tool should not be used at above its rated speed. Running over speed can cause tools to shatter explosively.

Cutting discs for these machines are very thin and unreinforced, despite the fact that they run at very high speed. This means that when they break in use they fly apart. Being extremely thin, they break very readily.

Wire brushes are prone to shedding bristles. These shed bristles come off at high speed, often sharp point first. Some wire brushes have a reduced speed rating.

Eye protection is a must with these tools, and one should stay out of the plane of spin of the tool.

A second risk results from high speed, tool inertia and absence of guarding. Catching a spinning tool on something can yank the machine forcefully. The machine should be held firmly, hands kept out of the way of the tool, and force on the workpiece should always be kept light.

Tools that cause vibration should be retired. These have become unbalanced, and are much more liable to fail dangerously in use. They also put high stresses on machine bearings causing premature failure.