Difference between revisions of "Flex"

(→Arctic: pic, colours) |

(→Cloth: pic) |

||

| Line 33: | Line 33: | ||

===Cloth=== | ===Cloth=== | ||

| + | [[image:Flex cloth 381-3.jpg|thumb|Cloth flex]] | ||

Flexes with a cloth outer have rubber inner insulation. These have a high temperature rated interior with an even higher temp rated outer surface. They are well known for their use on irons. | Flexes with a cloth outer have rubber inner insulation. These have a high temperature rated interior with an even higher temp rated outer surface. They are well known for their use on irons. | ||

Revision as of 21:17, 22 July 2008

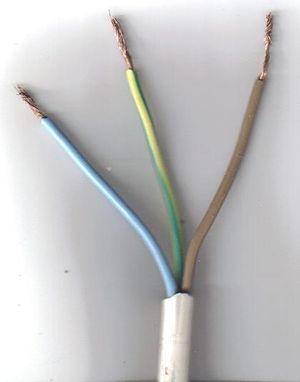

Flex is stranded electrical wire used for all plug-in mains appliance leads. It is also called flexible cable.

Cable on the other hand is unstranded mains wire not suited to repeated flexing, and is used for fixed installations.

2 Core Flexes

Flexes are available with 2 or 3 cores (conductors). 2 core flex is only suitable for appliances that don't need an earth connection (marked ![]() ), and should not be used for extension leads with 3 pin sockets.

), and should not be used for extension leads with 3 pin sockets.

2 core flexes are available in both round and oval shape. Oval (flat) uses less material, but any twisting of the flex is visible, whereas it isn't with round.

Multicore

Multicore mains flexes are also available for those uncommon tasks requiring more conductors. Non-mains multicores, such as alarm cable, are not suitable for mains use.

Insulation

PVC

Most flex has PVC insulation rated to 70°C.

90°C PVC is also available for use in hot locations.

Arctic

Arctic flex remains flexible at low temperatures, whereas regular PVC stiffens. Arctic flex is used for outoor appliances, eg on building sites. It is rated for use down to -40°C.

On sites yellow is used for 110v and orange for 240v.

Rubber

TRS (tough rubber sheath) is a flex with greater mechanical strength and damage resistance than PVC. It is used when some degree of rough use can be expected.

VIR is discussed further down.

Cloth

Flexes with a cloth outer have rubber inner insulation. These have a high temperature rated interior with an even higher temp rated outer surface. They are well known for their use on irons.

Old cloth insulated flexes are prone to kinking, with the inner rubber insulated wires poking out at the kinks. New cloth insulated flexes have a layer of rubber under the cloth that discourages this from happening.

The rubber inner insulation can harden and break at the ends. This is often seen on old cloth flexes. When this occurs the flex can be cut back several inches to reveal healthy flex, and reconnected.

Whats it called

the very soft high temp plastic insulation sometimes found on irons.

Figure of 8

Figure of 8 shaped plastic flex was formerly used for low current mains uses. It has a single layer of insulation only, and live conductors are easily exposed by minor damage. It was used in several colours, including black, brown, white and clear.

Such flex has been unlawful to fit to mains appliances for decades, but is still occasionally seen in use. Today this flex type is used as speaker wire.

Twisted Pair

2 core cloth & rubber (VIR) twisted mains flex with no outer sheath was once in common use. Most was dark red or brown. This flex has been obsolete for decades, and is rarely seen today. Occasionally its seen on historic electrical goods, and when found is usually in a dangerous condition. Apart from not meeting modern safety requirements, the rubber tends to harden, perish and disintegrate over time, exposing bare live wires. Despite once being in widespread use, it is rarely seen today because it deteriorates badly over time.

Conductor Sizes

- 0.5 mm²

- 0.75 mm²

- 1.0 mm²

- 1.5 mm² 13A

- 2.5 mm² 90°C flex is used for immersion heaters