Fluorescent Lighting

Fluorescent lighting is the most energy efficient lighting suited to widespread domestic use.

Fluorescent lighting can look good if chosen and installed well. But the all too common choice of a bare bulbed butt ugly glowstart fitting in the centre of the room with a tube chosen at random is a recipe for unpleasant lighting.

Types of fluorescent lighting

- Linear fluorescent have been with us since the 1930s.

- CFL compact fluorescent lamps are thinner tube lamps which run at higher output than traditional tubes. They are commonly found with integral ballasts in the bulb base designed to replace filament bulbs, but are also available to run from separate ballasts in the luminare.

- Circline tubes are a variation on the theme popular in the 1960s, and occasionally still used in homes.

- Miniature tubes have found use in emergency exit signs, torches, and small displays.

- HO high output and VHO very high output tubes are used in aquaria where high lighting density is required. These tubes have lower efficiency than standard tubes.

- CCFL cold cathode fluorescents are very thin tubes that backlight LCD monitor & TV displays. CCFLs are also used in scanners.

Linear fluorescent & CFL are by far the 2 most common types of fluorescent lighting.

History

The first installation in the UK was in a London Underground station in the 1930s. During WWII, fluorescent lighting was installed in many factories to help the war effort. These were all 5' 80W T12 (1.5" diameter) tubes, which used the same ballast as an 80W mercury vapour lamp and bayonet cap tube connectors, as these parts already existed at a time when manufacturing new parts was to be avoided where possible. 6' and 8' tube sizes followed.

In the 1950s, a 2' 40W tube for street lighting and the lower power-per-foot 4' 40W tube were introduced, and the 5' tube was reduced to 65W which resulted in more efficient operation. The new tubes were all bi-pin connectors, and the older tubes migrated to bi-pin connectors too. Glow starters replaced thermal and manual starters.

In the late 1970s, Thorn Lighting developed the lower power 8' 100W tube to replace 8' 125W tubes with only a tiny drop in light output. There followed replacement lower power tubes for all the other popular tube lengths, also intended to run in the original fittings with the same series ballasts. The 8' 100W tube is a T12, but all the other reduced power retrofit tubes are T8 (1" diameter).

In 1980, Philips introduced the SL18, the first integral ballasted compact fluorescent retrofit designed to replace a filament bulb. Thorn Lighting followed with the 2D compact fluorescent for the same purpose, but the tube and ballast were separable to enable tube and starter replacement without discarding the ballast. Compact fluorescents have always suffered from being larger than their GLS equivalents, but over the intervening years, this difference has reduced, meaning more light fittings can take compact fluorescent retrofit lamps.

Lamp sizes

T-values identify the tube diameter in 1/8ths of an inch, so T8 is a 1" diameter tube. Some other European countries specify T-values in millimetres instead, and sometimes these values are seen on packaging.

Common British tube sizes include:

- 8' 125W & 100W (both T12)

- 6' 85W T12 & 70W T8

- 5' 65W T12 & 58W T8

- 4' 40W T12 & 36W T8

- 2' 18W T8

- 21" 13w T5

- 12" 8w T5

- 9" 6w T5

- 6" 4w T5

Note that new fittings have not taken T12 tubes (except for the 8' 100W) for many years now, although T12 tubes remain available for older fittings.

Less common tube sizes include:

- 8' 80W T12 (obsolete)

- 6' 75W T12 (obsolete)

- 5' 80W T12 (power rating of 5' tubes prior to 1960)

- 3' 30/33W T12 & 30W T8

- 2' 20W T12

- 21W

New ranges of T5HE (High Efficiency) and T5HO (High Output) tubes are commonly used in new commercial luminares, and now starting to be used in domestic use too. They're 2" shorter than the above lengths, and not compatible with old T8/T12 fittings.

T4 tubes are commonly used in domestic situations for things like under-cupboard lighting, but the tube lengths and power ratings are not standardised between manufacturers. This results in premature installation failures at times when a manufacturer stops selling the tubes.

Good fluorescent lighting

Good fluorescent lighting needs the following points:

- Hidden bulb

- Hidden or stylish light fitting

- Even well distributed lighting

- Comfortable light level

- No flicker or flash

- A tube of good light quality (many aren't)

- Tubes of a size that makes keeping a spare practical

For 1 2 & 3 - Trough fittings (uplighters) achieve these.

For 4 - Fluorescents are around 4x as energy efficient as filament bulbs, so a quarter the power of comfortable filament lighting is a good starting point.

For 5 - An electronic ballast fitting avoids all the flicker and flash of cheap glowstart fittings.

For 6 - see the next section

For 7

- 2 foot tubes are easy to store anywhere

- 4' give much more light and are storable

- 5' tubes are good for garages etc. The light output per fitting is on the high side for indoor use, and indoor storage can be awkward in some houses

Fluorescent Tube Types

There are many different versions of white, ranging from excellent quality to dire. Buying tubes at random can give you unsatisfactory lighting.

Tubes are normally marked with their colour on on the glass at one end. Many shop assistants are unaware that there are different versions of white, or that the tubes are thus marked.

The Many Different Whites

Tubes marked simply as white are not of the best quality, though not the worst.

I can recommend 2700K and 3500K tubes, but not recommend higher colour temperature tubes for household use.

2700K is the colour of GLS filament bulbs, so it matches perfectly with traditional filament lighting. 2700K is a warm slightly yellowy white.

3000K is the colour of halogen bulbs, cleaner and crisper than 2700K. Some 3000K tubes don't have good CRI*, so if you want 3000K to match halogen its best to pick the more expensive triphosphor tubes rather than halophosphates.

3500K will not match other light sources, unless they're also 3500K fluorescent, but used alone they give a fresh clean look. These are my favourite tubes for domestic lighting.

4000K look cold and anaemic to most people (though there are some that like them), and 4500K and up are like the old fashioned 'cool white' tubes that once gave fluorescent lighting such a bad reputation. There are also proprietary numbering systems, such as the Philips system.

Cool white and daylight are ill suited to domestic use.

More information on many more tube types

Philips Numbering System

Philips tubes may be marked with a 3 digit colour code as follows:

First digit:

- 7 = 70-79% CRI

- 8 = 80-89% CRI

- 9 = 90-100% CRI

Last 2 digits give the colour temp, eg 35 is 3500K.:

Example: An 827 tube has 80-89% CRI and 2700K CCT.

Phosphor types

There are 2 phosphor chemistries in use today: halophosphate and triphosphor.

The older halophosphate tubes come in many versions of white, and have a wide range of CRIs from the 50s (grim) to over 90 (excellent).

T8 Triphosphor tubes have consistently higher CRI than halophosphate (80s to 90s), slightly higher lumen output per watt, and output doesn't reduce as much over time as halophosphates. The tubes cost more.

- CRI = colour rendering index, a measurement of how well fluorescent tubes render colour. 100 is perfect, 50 is bad.

Fitting Types & Installation Methods

* is the fluorescent tube

|// is the wall

Trough

| * |//

|___|//

|//

|//

The trough encloses both tube and light fitting in a trough, so neither are directly visible. The trough is open at the top for uplighting, or the bottom for downlighting.

Uplighting troughs are a very good general purpose lighting method, giving excellent results in most cases for general purpose lighting. They can provide relatively even lighting, and avoid all glare & bright areas. They work very well in domestic sized rooms, and also in larger spaces with a high ceiling.

Uplighting troughs give the best light spread if the trough is moved away from the wall a bit. Small troughs with tubes close against the wall tend to highlight plaster imperfections and create high brightness patches.

Downlighting troughs are useful where it is desired to restrict the light output to a limited area.

Shelf

[]* |//

______|//

|//

|//

The fitting is sat on a shelf, turned with the tube facing the wall so the tube is not directly visible.

The quality of light spread is as good as the trough fitting, with relatively even uplighting and no glare. But the fitting itself remains visible, and they are generally not designed with aesthetics in mind.

A good option for lighting in garages, workshops, etc. The shelf should be painted white or paper used.

Downlighter

_____ | * |

Ceiling mounted downlighters are popular in office and retail premises. They come in surface mount and flush recessed types. They are well suited where high illumination levels are required, and white or near-white flooring is used. Other flooring colours result in significant reduction in energy efficiency.

They aren't well suited to home use as they put out a lot of light over a limited area only.

Bare & basic

_ [_] *

A bare tubed light on the ceiling is a basic way to use fluorescents, and is popular with nonprofessional installs. It works, but lightspread is not great with shadows all round, the bare tube creates glare, and the ugly fitting is visible and brightly lit.

Diffuser

Diffusers improve the appearance of fittings, but are generally not very good at eliminating glare. A bare bulb covered with a diffuser is not one of the best options.

Shadowless

Installing bare fluorescent lights in several continous lines was for decades a preferred method for rooms where people work at desks. It is a simple way to provide very little shadow on the work. This is a minimum cost way to install fluorescent lighting for work, but is now mostly replaced by more modern methods.

Glare can be quite bad with these installs. Reflectors may be fitted to greatly reduce this problem.

One of the minor advantages of this approach is that the light from adjacent fittings mixes well, so it works well with a random mixture of tube types.

This method remains a fairly good choice for minimum cost work areas where the cheapest fittings and tubes will always be used.

Above cupboard

Low power lights fitted above kitchen cupboards can contribute a good amount of light to the room while keeping the fittings and tubes not visible.

These are effectively shelf fittings. Their weakpoint is that the cupboard tops need dusting otherwise light output drops. They are also not suitable for use with low ceilings, as the tubes would then be visible from across the room.

Under cupboard

A very effective way to light kitchen worktops. Don't overdo the light output.

A switch on each fitting enables some variation of lighting level after fitting. Putting every other fitting on a 2nd lightswitch makes a more relaxed comfort lighting level available at the press of a switch, also improving energy efficiency.

A dimming ballast enables good control of light level and reduces energy use, but adds to the price.

Single Long Tube

It is possible to use a single long tube for under cupboard lighting instead of several small ones. This can improve reliability and cost, and give perfectly even lighting at all light levels. However a dimming system is a must, as the full output power of a long T8 tube will be far in excess of what is required.

The tube should be mounted to the cupboard underside with clips, and the control gear housed in a separate box. Standard ceiling fittings are too bulky.

Disguised Supplemental Lighting

The idea of this is to provide part of the room's light without the fluorescent lighting being seen. Trough uplighting is generally best for the fluorescents.

This approach retains the appearance of non-fluorescent lighting while providing some of the energy efficiency and reliability advantages of fluorescent.

Ballast Types

All modern fluorescent lighting ballasts fall into one of 2 categories

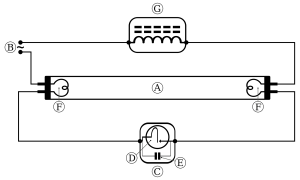

- Electromagnetic ballast (pictured) with glow starter

- aka iron ballasts

- aka choke ballasts

- aka inductor ballasts

- aka wound ballasts

- Electronic ballast

- - several types

Note: North America uses the same names in many cases to mean completely different things from rest of the world. UK/International terminology is used here.

Switchstart

Switchstart (also known as "pre-heat" in the US) is the most popular ballast type in Britain and most other countries with 220/240V mains. They are easily identified by their starting behaviour, they usually flash a few times during starting.

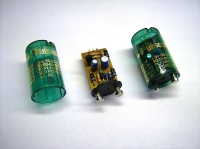

Switchstart fittings (nearly always) use a plug-in glowstarter. These starters are consumables.

Some domestic fittings have the starter under the removable panel, and these starters rarely fail unless the fitting is left operating with a dead tube in it for a long time.

In commercial environments the starter will often be replaced at the same time as the tube to minimise failures and labour costs.

There are a few different ratings of glowstarter, all of which look the same. The ratings for each vary between manufacturers, but the most common ratings are:

- 4-65W and 4-80W for general purpose use.

- 4-20w glowstarters for the lower power tubes only

- 100-125w glowstarters for 8' tubes only

- Series starters for fittings that run 2 tubes in series. These are sometimes marked as 110 / 120v / 110-130v starters.

All are a (normally) plastic can with a 2 pin base. Any metal starter cans will be decades old.

Electronic replacements for these glow starters are available. These are a direct swap, and are also available in wire-ended versions for wiring into the fitting (as they don't wear out). Most electronic versions don't keep trying to start a dead tube.

Thermal Starters

Thermal starters are visually better than glowstarters, as they avoid any flicker and flash during starting. They just wait a few seconds then switch on. They were obsoleted by glowstarters in the 1950s. Thermal starters look similar to glowstarters, but have a 4 pin base. They start with no flashing, but take longer than glowstarters. If the light is switched off for a second they generally don't relight, they need a very brief cooling off first. 4 pin starter cans continued to be produced during the 60s for replacement purposes, but contain a glowstarter instead. The original thermal starters consume around 1w during running.

If the performance of a thermal starter is wanted for an old fitting, its relatively simple electronics to make a relay time delayed with a diode, resistor and capacitor.

Electronic

There are various types of electronic ballast. All start with no flashing. Pre-heat will heat the filaments for something between 0.5 and 1 second before striking the tube, and Instant start will strike the tube pretty instantly (manufactures usually specify < 0.1seconds). (Unfortunately, the term "Instant Start" is also used sometimes to refer to any type of electronic control gear, so you must check manufacturer's data sheet if you really want an instant start ballast.)

All the minature T4 and new T5HE and T5HO lamps can be driven only by electronic control gear.

Other Magnetic Ballast Types

There were also a number of types of starterless ballasts which were used before electronic ballasts became viable. They were mostly used in commercial installations, rather than in homes, as they were more expensive.

- SRS (Semi-resonant start), invented by Thorn Lighting, uses a double wound transformer and essential circuit capacitor. The tube lights up steadily over about 5 seconds without flashing, just like a light being brought up on a dimmer. It was particularly suitable for low temperature (outdoor) use with the longer tubes, but cannot be used with the shorter tubes. (T8 replacement tubes should not be used with SRS ballasts.)

- Quickstart, use filament heating transformers. The filament heating supply is reduced when the lamp lights. They light similarly to SRS, but typically in a second. The quickstart filament transformer is often a separate unit from the ballast, but the two can be combined in one can in other cases.

- Rapid Start, use filament heating transformers. The filament is continuously heated. They light similarly to Quickstart. Rapid Start ballasts (sometimes referred to as dimming ballasts) can be dimmed with special dimmers if the filament transformer supply is separate from the tube current supply.

- Instant start, is mentioned only for the benefit of US readers, they are not used in the UK.

CFL Ballasts

These are electronic ballasts, and working ballasts can be reused to run the smaller T8 or T12 linear tubes. They are designed as disposable items, with shorter lives than ballasts designed for linear tubes, but separating ballast from tube runs them much cooler, and prolongs their life greatly.

Capacitor Ballasts

Capacitor ballasts are found in workshops using rotating machinery. They are like glowstart fittings except that the choke ballast is replaced by a capacitor ballast, plus a small choke to reduce the crest factor (high peak current) inherent in capacitive ballasts which causes rapid wear of the tube electrodes.

They produce light out of phase with standard choke ballast lights. Choke and capacitor ballast circuits are used side by side, known as lead/lag pairs, to minimise 100Hz flicker, and thus eliminate the risk of strobing on rotating machinery, which can in some cases to a limited extent give the impression that a moving machine might be stationary. Leag/lag pairs can either be supplied as twin lamp fittings with one tube on a capacitive (leading) ballast and the other on an inductive (lagging) ballast, or as a packing carton of single lamp fittings which are mixed, half capacitive, half inductive. Circuits using lead/lag pairs do not require power factor correction capacitors with the inductive ballasts as the capacitive ballasts cancel out the phase shift of the current.

The drawback with capacitor ballasts is the high crest factor (a current peak is dumped through the tube every half cycle when the gas discharge starts conducting and suddenly has to change the charge in the capacitor). This is a second reason why a small choke ballast is still required, to limit the current peak and reduce the bad effect on tube life. Electronic ballasts are preferred to lead/lag pairs now.

Hybrids

Finally there are hybrid systems sometimes found, typically retrofits from the late 1980s. These are conventional iron electromagnetic ballasts with electronic starters fitted later.

Performance varies depending on the design of the starter. Most are good, but the behaviour of the worst can be unpleasant.

Energy Efficiency of Fittings

Ballast efficiency is marked with an EEI (Energy Efficiency Index) rating on the ballast.

For a 58W tube and electromagnetic ballast, max ballast losses are: EEI=

- D: >12W

- C: 12W

- B2: 9W

- B1: 6W

- A3

- A2

- A1

It's no longer legal to sell EEI= C or D ballasts in the EU.

Electronic ballasts are more efficient, required to meet ratings of A1, A2 and A3. These have much lower energy loss than electromagnetic ballasts. Electronic ballasts also operate the tube at high frequency, producing around 9% increase in tube efficiency.

Obsolete thermal starters, rarely seen now, consume around 1w watt during running. This is in addition to the electromagnetic ballast losses.

Energy Efficiency of Tubes

Several factors affect the energy efficiency (efficacy) of fluorescent tubes, and tube efficiency spans a fair range, from around 50 lumens/watt to just over 100 for a 4' tube. (Link) to table of tube efficacies.

Tube diameter

T5 has greater efficacy than T8, which has greater efficacy than T12.

Tube Length

Long tube sizes are more efficient, but they produce too much light for most domestic situations, resulting in nothing but unnecessary energy use.

Large tubes may be suitable for large high ceiling rooms, and areas where lighting quality is a low priority, such as garages.

Phosphor

The internal fluorescent coating produces most of a tube's visible light output. There are 2 families of phosphor in common use.

Halophosphate tubes have been with us for many decades. Light output declines significantly over time. CRI percentage varies from the 50s (fairly horrid) to 90s (excellent light quality).

Triphosphor tubes give slightly higher light output than halophosphate, and decline in light output over time is less. CRI is more controllable, thus is normally high for triphosphor tubes. Price is generally higher for triphosphor tubes.

White vs White

For any given tube type, efficacy varies between warm white, cool white and daylight.

Tubes marked deluxe are typically much lower efficacy. Its common for them to only put out 50-70% as much light.

Colour tubes

Most colour fluorescent tubes are made by using only one colour of fluorescence. In other words all the light output is produced as the wanted colour. Contrast this with coloured filament lighting, where white is produced, then most of this light is filtered out, giving a heavy drop in total light output.

Consequently colour fluorescent lighting is more energy efficient than filament by a much greater margin than comparing white light.

There are also colour tubes that are white with a colour filter layer. These still have much greater output per watt than filaments, but not by the even greater extent of the above type.

Output also varies significantly between colours. Displays of assorted colour tubes show much variation in perceived brightness.

Dimming

This section deals with domestic dimming, other methods aren't useful for DIY.

Dimmers

Most fluorescent fixtures are not compatible with standard dimmers. Dimmable fixtures are available, but both dimmer and light fitting must be compatible with each other.

Dimming produces a small drop in energy efficiency, meaning that reducing light level does save significant energy. This is in sharp contrast to filament bulbs, whose energy efficiency plummets rapidly on dimming.

Generally speaking, and it is only possible to be general on this, dimming fluorescents often save more energy and money than the dimmer costs and took to make, making dimmable electronic fittings a good choice on energy, money and comfort grounds.

Dimming does not prolong tube life. If not done properly, dimming by more than 20% reduces tube life significantly.

Dimming protocols

1-10v: A 1-10v signal from the dimmer controls light output proportionally. When controlling more than one fitting, light output levels don't always match.

Properietary standards also exist, which are incompatible with other brands and fitting types. Dimming range & consistency of light output vary.

DALI: Modern sophisticated digitally addressable dimming. Compatible between brands, more consistent light output.

Switchbanks

Switchbanks are an alternative to dimmers and dimmable ballasts, with lower cost and excellent money & energy payback. However these are sometimes inconvenient to retrofit. Where practical they should be fitted, since their utility and payback are both many times their very small extra cost when DIYing.

Switchbanks have an additional minor advantage when used with low cost glow starter fluorescent fittings. Glow starter fittings often fail to a flickering flashing state, and a switchbank is an easy way to avoid this problem temporarily until the fitting is relamped or its starter replaced.

A switchbank can be anything from a 2 gang switch to a whole panel of switches, one for each fitting.

Both

Switchbank and dimming can be combined for best energy saving.

Historic methods

Variac: a variable voltage output transformer feeds a standard electromagnetic ballast. When left in dimmed mode tube life is much reduced and dimming range limited. Starting when dimmed isn't graceful.

Salt water tank: An electrode is raised & lowered in a tank of salt water. This variable resistance goes in series with the mains feed to the fitting. Much the same problems as the above, plus the risk of a live saltwater tank and worse energy efficiency.

Neither is recommended for current use.

Tube Life

Tube life depends on

- tube rated life (typicaly 20,000hrs)

- type of ballast (aka tube top)

- how often the tube is switched on and off

- type of starter (where used)

Most electronic ballasts give the longest tube life, though ones that strike the tube in under a second reduce tube life. Tubes are typically rated at 20,000 hours on electronic gear.

Glowstart fittings with iron ballasts typically halve tube life.

Thermal starters give longer tube life than glowstarts, due to proper preheating and once-only strike. Exact figures are hard to find, but most likely they produce the same tube life expectancy as electronic ballasts.

Tubes left always on can be expected to last around twice as long. Very frequent switching (well over 20 times a day) makes little difference on electronic ballasts, but can almost halve tube life on switchstart. Cold cathode instant start fittings kill tubes quickly if switched often.

Where lamp life needs to be maximised, tubes of up to 60k rated hours are available.

Light Output

Light output declines over time, and in commercial installations tubes are routinely replaced before they die, for 3 reasons:

- To maintain energy efficiency

- Replacing all at once is much cheaper in labour than replacing them one at a time as they die

- Avoiding the high failure rate near end of life also eliminates the regular appearance of dead or malfunctioning light fittings, which would look bad in retail premises.

Triphosphor tubes suffer much less output reduction than the older halophosphate technology, so the most economic method of running these is to give them a longer service life than with halophosphate tubes.

Wiring

There is one gotcha when wiring up used fluorescent fittings. Most old ballasts run hot, and standard pvc insulated wire must not be routed over the iron ballast. Most switchstart fittings either used high temp rated internal wiring where it passed over the choke, or used a metal shield/channel to keep the wiring cooler.

Fluorescent lights must always be earthed, they should not be connected to historic 2 core lighting circuits. Most fluorescent fittings generate starting voltage pulses well above mains voltage.

Plant Lighting

Plants require high lighting levels without excessive heating or cost. Fluorescent lighting is ideal for lighting small numbers of indoor plants.

Grolux tubes produce a pinkish light well suited to plant lighting.

Many people have also used cool white tubes for plants. These have 2 advantages, they're much cheaper and they give a white light. They work well, though aren't optimised for plant growth.

Note that fluorescent plant lighting should generally be placed as close as safely possible to plants, not 5 feet away on the ceiling.

Plants in bulk are better lit by discharge lighting, HID or sodium.

Other Fluorescent Lamp Types

This article addresses domestic lighting. There are also other types of fluorescent lamps, such as

- blacklight (UV)

- blacklight blue (UV)

- germicidal (UV) - never expose eyesight to these

- inductively driven electrodeless lamps

- microwave driven electrodeless lamps - well outside of DIY

Power Factor

This is only significant to most DIYers when buying new fluorescent fittings.

Choke and electronic ballasts do not inherently have a power factor of 1. This means the mains current waveform is not the same as (and in phase with) the voltage waveform. While this is trivial with 1 or 2 domestic lights, it can cause real problems with larger commercial installations.

Fittings are available in 2 types:

- LPF (low power factor)

- HPF (high power factor)

LPF fittings use uncompensated ballasts, and are suitable where external power factor correction is used, and for situations where PF is not important.

HPF fittings contain power factor correction, and purchase cost is thus very slightly higher.

In DIY situations there are normally no consequences if you fit HPF instead of LPF, or vice versa. The situations where the difference will be evident are:

- Lighting run off generator, UPS or invertor.

- Large quantity of fluorescent lighting in use

- Lighting circuits loaded to a high percentage of their current rating.

In these cases HPF fittings are recommended.

When LPF electromagnetic fittings are used, a snubber should be connected across the fitting to prevent damage to the switch feeding it.

Outdoor use

Fittings should of course be rainproof, though non-weatherised fittings were sometimes fitted under the edge of the roof. Insects in such fittings can trip an RCD, so its not really good practice.

Fluorescent tubes need higher voltage to strike when very cold, so any ballast used should be rated for outdoor use.

- New outdoor rated ballasts will be electronic.

- Old outdoor fittings tend to use SRS ballasts, these start T12s but can fail to light T8s when too cold.

T5s are badly affected by cold, and not really suitable for outdoor use. They put out about 18% light output at 0C, T8s put out over 80%.

Cheaper to leave it on?

There is a persistant myth that leaving a fluorescent light on is cheaper than switching it off. There is simply no situation in which this is the case. The power use during switch starting is around 3x run power, so the 1 second starting routine uses as much energy as leaving the lamp on for 3 seconds. The effect on tube life is trivial cost-wise.

Occasionally the reason given for leaving a tube on is that that tube life is prolonged. It is, but

- that extra tube life and more is used up uselessly, so tube life may be more hours but its less days

- the cost of the extra energy used exceeds the value of the tube life.

UK vs US

US fluorescent lighting practices, ballast types, tube types, cost and common issues are different to those of the UK. To make matters worse, the terminology is also different, and in some cases the same terms are used to mean something different here versus there. This causes many a crossed wire.

Wireless operation

Fluorescent tubes can be made to appear to be operating wirelessly for novelty value.

- The tube is mounted so that the end pins are visible, with nothing connected to them. Tool clips (terry clips) are a simple option.

- LEDs are mounted along the rear of the tube

- The LEDs are low voltage powered via thin enamelled copper wire, which is almost invisible.

To Do

- disposal

- troubleshooting / repair