Difference between revisions of "Halogen Lights on Long Cable"

(→Voltage Dropper: 2d maths) |

|||

| (11 intermediate revisions by the same user not shown) | |||

| Line 3: | Line 3: | ||

Low voltage [[Halogen Lighting|halogens]] can be run on long [[Cables|cables]] if there is a good reason to do so, but long [[Cables|cables]] introduce significant [[Cables|voltage drop]], and this issue must be addressed one way or another. | Low voltage [[Halogen Lighting|halogens]] can be run on long [[Cables|cables]] if there is a good reason to do so, but long [[Cables|cables]] introduce significant [[Cables|voltage drop]], and this issue must be addressed one way or another. | ||

| − | Ignoring the [[Cables|voltage drop]] issue results in bulbs running at well below intended light output, and well below their usual level of energy efficiency. | + | Ignoring the [[Cables|voltage drop]] issue results in [[Halogen Lighting|bulbs]] running at well below intended light output, and well below their usual level of energy efficiency. |

If [[Cables|voltage drop]] differs between bulbs it also results in uneven lighting appearance and differences in colour temperature. This does not make a lighting installation look good or perform well. | If [[Cables|voltage drop]] differs between bulbs it also results in uneven lighting appearance and differences in colour temperature. This does not make a lighting installation look good or perform well. | ||

| Line 10: | Line 10: | ||

=The options= | =The options= | ||

* Avoid the Issue Entirely | * Avoid the Issue Entirely | ||

| + | ** place transformer close to bulb | ||

| + | ** don't use very high frequency transformers with more than a couple of feet of cable | ||

* Minimise voltage drop | * Minimise voltage drop | ||

** Thick [[Cables|cable]] | ** Thick [[Cables|cable]] | ||

| Line 25: | Line 27: | ||

==Avoid the Issue Entirely== | ==Avoid the Issue Entirely== | ||

| − | The voltage drop problem only occurs wth low voltage high power consumption lamps on long cable runs. Changing to any of the following would remove the cable issue: | + | The [[cables|voltage drop]] problem only occurs wth low voltage high power consumption lamps on long [[cables|cable]] runs. Changing to any of the following would remove the cable issue: |

| − | * mains voltage halogen | + | * [[Halogen Lighting|mains voltage halogen]] |

* any other mains voltage lighting | * any other mains voltage lighting | ||

| − | * 12v CFL | + | * 12v [[CFL Lamps]] |

| − | * 12v | + | * 12v [[Fluorescent Lighting]] |

However in some cases 12v lighting is wanted, and when long cable runs are involved it is an issue that can be worked around in various possible ways. | However in some cases 12v lighting is wanted, and when long cable runs are involved it is an issue that can be worked around in various possible ways. | ||

| Line 37: | Line 39: | ||

This is the option most often chosen to minimise V drop, and the simplest. The [[Cables]] article gives [[Cables|cable voltage drop]] for any given current. | This is the option most often chosen to minimise V drop, and the simplest. The [[Cables]] article gives [[Cables|cable voltage drop]] for any given current. | ||

| − | However this approach has its limits, and can lead to the need for impractical [[Cables|cable sizes]] | + | However this approach has its limits, and can lead to the need for impractical [[Cables|cable sizes]] sometimes. |

| − | |||

===Parallel Cables=== | ===Parallel Cables=== | ||

| Line 51: | Line 52: | ||

===Extreme Cables=== | ===Extreme Cables=== | ||

| − | Very large cables can effectively address voltage drop. The prime candidates are: | + | Very large [[cables]] can effectively address voltage drop. The prime candidates are: |

| − | * Very large stranded cable as used by supply utilities, and for arc welders, jumpleads, etc | + | * Very large stranded cable as used by supply utilities, and cable for arc welders, jumpleads, etc |

| − | * Copper water pipe with soldered joints | + | * Copper [[plumbing|water pipe]] with soldered joints |

| − | * Steel cable could be used in principle, but requires around 10x the cross sectional area of copper for the same voltage drop. | + | * Steel cable could be used in principle, but requires around 10x the cross sectional area of copper for the same [[cables|voltage drop]]. |

When used, such megaconductors are often made a feature of. (With a little ingenuity a water valve in the pipe could even be made to turn the lights off.) | When used, such megaconductors are often made a feature of. (With a little ingenuity a water valve in the pipe could even be made to turn the lights off.) | ||

| Line 90: | Line 91: | ||

| − | This trick | + | This trick doesn't work with electronic transformers. |

===15v Transformer=== | ===15v Transformer=== | ||

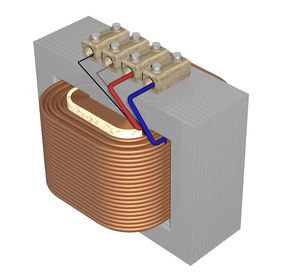

[[image:Transformer-diag.jpg|thumb]] | [[image:Transformer-diag.jpg|thumb]] | ||

| − | 15v rectangular transformers are widely available from electronic component suppliers. These are larger than the equivalent toroidals. These supply the necessary 12v plus a | + | 15v rectangular transformers are widely available from electronic component suppliers. These are larger than the equivalent toroidals. These supply the necessary 12v plus a 3v margin. Part of the 3v not needed is lost in [[cables|cable drop]], the rest is lost by any of: |

* removing turns from the transformer | * removing turns from the transformer | ||

| − | * an added voltage dropper | + | * changing transformer mains tapping |

| + | * an added voltage [[droppers|dropper]] | ||

| − | Note that these transformers are designed to be built into equipment, and generally have no fusing, no overheat cutout, and bare live terminals. They should be bolted into a box (earthed if metal), with | + | Note that these transformers are designed to be built into equipment, and generally have no [[fuse|fusing]], no overheat cutout, and bare live terminals. They should be bolted into a box (earthed if [[metal]]), ventilated if [[plastic]], with suitable [[fuse]]s on both mains and secondary sides. |

These transformers exhibit the same deregulation as toroidals, so any voltage measurements should be taken with the same load as will be used permanently. | These transformers exhibit the same deregulation as toroidals, so any voltage measurements should be taken with the same load as will be used permanently. | ||

| Line 105: | Line 107: | ||

To ensure transformer current rating is sufficient, transformer rated power (in watts) should be 25% (or more) above total connected lamp load. | To ensure transformer current rating is sufficient, transformer rated power (in watts) should be 25% (or more) above total connected lamp load. | ||

| − | + | [[Fuse]]s for 12v/15v equipment transformers: | |

* Load current (A) = attached lamp power (watts) / 12v. | * Load current (A) = attached lamp power (watts) / 12v. | ||

* Secondary fuse = Load current x apx 1.3 - 1.5 | * Secondary fuse = Load current x apx 1.3 - 1.5 | ||

* Primary fuse: 1.5A | * Primary fuse: 1.5A | ||

* Both fuses need to be time delay (T) types. These have a spring-like interior construction. | * Both fuses need to be time delay (T) types. These have a spring-like interior construction. | ||

| + | |||

====Remove Turns==== | ====Remove Turns==== | ||

| − | Removing turns from the transformer secondary reduces voltage output. 4 turns per volt is typical for such mains transfomers. | + | Removing turns from the transformer secondary reduces voltage output. 4 turns per volt is typical for such mains transfomers. Toroidals can only be turn altered when their centre isn't [[glue]]d, and gluing is the most popular way to make them. Look for one with a central [[bolt]], discs and rubber pads instead. Never overtighten the central bolt, its easy to ruin toroidals this way, they aren't at all robust in this respect. |

| + | |||

| + | |||

| + | ====Tap changing==== | ||

| + | Some mains transformers, mostly old ones, have taps on the primary side for more than one mains voltage. (It was once common to see taps for 200,220,240,250v.) When the taps include 250v, this can be used instead of 240v to reduce V_out to 240/250 x 15v = 14.4v. | ||

| + | |||

| + | Using a 12v transformer on a tap of below 230v is not recommended, if mains voltage goes up some it can overheat. | ||

====Voltage Dropper==== | ====Voltage Dropper==== | ||

| − | This option comes with issues. | + | This option comes with issues, but is usually necessary with 15v transformers. |

| − | A resistor makes a simple dropper, but the high power dissipation makes for a waste of power and money. Dropping 3v with a resistor reduces energy efficiency by 25%, and can add a lot to the electricity bill over the years. Resistor droppers are defintely not recommended. | + | A resistor makes a simple [[droppers|dropper]], but the high power dissipation makes for a [[Save Energy & Money|waste of power and money]]. Dropping 3v with a resistor reduces energy efficiency by 25%, and can add a lot to the electricity bill over the years. Resistor droppers are defintely not recommended. |

Power resistors also run very hot, and suitable care is needed to ensure flammable materials can not come into contact. | Power resistors also run very hot, and suitable care is needed to ensure flammable materials can not come into contact. | ||

| − | Chokes (inductors) make much better droppers, without the heat, run cost and fire problems of resistors. However the calculations required to pick the right choke are more complex, requiring 2 dimensional maths. | + | Chokes (inductors) make much better [[droppers]], without the [[heat]], run cost and [[fire]] problems of resistors. However the [[droppers|calculations required]] to pick the right choke are more complex, requiring 2 dimensional maths. |

When using droppers, each lamp should have its own dropper, otherwise normal lamp failures will cause overvoltage and additional lamp failures. | When using droppers, each lamp should have its own dropper, otherwise normal lamp failures will cause overvoltage and additional lamp failures. | ||

| Line 131: | Line 140: | ||

[[Low Voltage Wiring#Enamelled Copper|Enamelled copper wire]] of the same (or larger) size as the output winding already uses should be used to maintain the transformer temp rating and avoid significantly reducing heat dissipation ability. | [[Low Voltage Wiring#Enamelled Copper|Enamelled copper wire]] of the same (or larger) size as the output winding already uses should be used to maintain the transformer temp rating and avoid significantly reducing heat dissipation ability. | ||

| − | When the extra winding is connected it will either reduce or increase the V output. If its reduced, swap the connections of the extra winding round. | + | When the extra winding is connected it will either reduce or increase the V output. If its reduced, just swap the connections of the extra winding round. |

4 turns per volt is typical for mains transformers. When measuring V_out, bear in mind that V_out varies significantly depending on load for wound transformers, so the intended bulbs should be used as a load when measuring V_out. | 4 turns per volt is typical for mains transformers. When measuring V_out, bear in mind that V_out varies significantly depending on load for wound transformers, so the intended bulbs should be used as a load when measuring V_out. | ||

| − | Many toroidal transformers are partly potted to reduce the chance of buzz. These can't be rewound, you need to use a non-potted transformer. These | + | Many toroidal transformers are partly potted to reduce the chance of buzz. These can't be rewound, you need to use a non-potted transformer. These use 2 metal discs, one on top and one underneath to bolt the transformer in place. Rubber pads insulate and spread the load under the discs. When doing up the central fixing bolt afterwards, go easy with the pressure. Overtightening is a cause of toroidal failure, and the extra winding will reduce the amount of force the toroidal structure can withstand. |

| − | It is not stictly necessary to use any central bolt fixing, the transformer can just be laid in place if it will never be moved, if preferred. When doing this, best sit it on rubber feet to avoid the possibility of hum or buzz. | + | It is not stictly necessary to use any central bolt fixing with toroidals, the transformer can just be laid in place if it will never be moved, if preferred. When doing this, best sit it on rubber feet to avoid the possibility of hum or buzz. |

===Wave Shaping=== | ===Wave Shaping=== | ||

| Line 158: | Line 167: | ||

| − | The transformer output is fed through a bridge rectifier, to a reservoir capacitor, and then to the light bulbs. The reservoir capacitor increases rms output by widening the | + | The transformer output is fed through a bridge rectifier, to a reservoir capacitor, and then to the light bulbs. The reservoir capacitor increases rms output by widening the wave shape of the waveform. |

| − | This technique should only be applied to non-electronic transformers, ie toroidals and rectangular iron core | + | This technique should only be applied to non-electronic transformers, ie toroidals and rectangular iron core [[transformer]]s. |

| − | The bridge rectifier's current rating needs to be well above the rms lamp current to deal with peaks and starting surge. Starting current is limited by transformer resistance, and is typically in the region of | + | The bridge rectifier's current rating needs to be well above the rms lamp current to deal with peaks and starting surge. Starting current is limited by transformer resistance & lamp resistance, and is typically in the region of 5x run current. |

| − | You'll need a true rms reading voltmeter to set this up accurately. It is also possible to set it up approximately by comparing by eye one lamp on a very short cable next to another identical lamp on the full length of cable you | + | You'll need a true rms reading voltmeter to set this up accurately. It is also possible to set it up approximately by comparing by eye one lamp on a very short cable run direct from the transformer next to another identical lamp on the full length of [[cables|cable]] you'll use fed via the wave shaper. |

The larger the capacitor, the more rms voltage boost occurs. Transformer power rating should be 50% higher than the lamps it will run. The size of capacitor used is much smaller than those used as PSU reservoirs, as the aim is just to extend the peak a little rather than provide near peak voltage for a whole half cycle. | The larger the capacitor, the more rms voltage boost occurs. Transformer power rating should be 50% higher than the lamps it will run. The size of capacitor used is much smaller than those used as PSU reservoirs, as the aim is just to extend the peak a little rather than provide near peak voltage for a whole half cycle. | ||

| Line 170: | Line 179: | ||

Schottky diodes need to be used rather than cheaper silicon diodes to keep voltage drop down. Don't be tempted by cheaper non-schottkies, you would pay the difference in power use many times over each year. | Schottky diodes need to be used rather than cheaper silicon diodes to keep voltage drop down. Don't be tempted by cheaper non-schottkies, you would pay the difference in power use many times over each year. | ||

| − | This method introduces about a total 0.8v drop in the 2 conducting schottky diodes, resulting in an energy efficiency reduction of apx 6-7%. | + | This method introduces about a total 0.8v drop in the 2 conducting schottky diodes, resulting in an energy efficiency reduction of apx 6-7%. Expect the diodes to run hot. |

| + | |||

| + | 50w of 12v bulbs need around 33uF to increase mean V_out by 1%, so restoring the 0.8v lost in the rectifier takes around 220uF. Required capacitor size is proportional to lamp power load. Capacitors should be 25v rated (higher is ok). | ||

===Tweaking an Electronic Transformer=== | ===Tweaking an Electronic Transformer=== | ||

| Line 178: | Line 189: | ||

===Series Bulbs=== | ===Series Bulbs=== | ||

| − | Running 2x 12v bulbs in series on 24v reduces the voltage drop problem by a factor of 4. It halves the current draw of the pair, halving voltage drop, plus a given absolute amount of voltage drop has only half as much effect on each lamp's operating voltage. | + | Running 2x 12v bulbs in series on 24v reduces the [[cables|voltage drop]] problem by a factor of 4. It halves the current draw of the pair, halving voltage drop, plus a given absolute amount of voltage drop has only half as much effect on each lamp's operating voltage. |

| − | This approach makes | + | This approach makes cable runs 4x as long practical. The downsides are: |

| − | * When one bulb blows, both | + | * When one bulb blows, both go out. |

* The 2 bulbs must always be the same wattage as each other (fitting 2 different wattage lamps would cause one lamp to fail) | * The 2 bulbs must always be the same wattage as each other (fitting 2 different wattage lamps would cause one lamp to fail) | ||

| Line 196: | Line 207: | ||

The LED lights up when the bulb its wired across dies. | The LED lights up when the bulb its wired across dies. | ||

| − | A cheaper single colour LED | + | A cheaper single colour LED can be used with a diode across it, wired in reversed parallel. Never omit the diode. |

| − | o----/\/\-----+----|>|-----+-----o | + | o----/\/\-----+----|>|-----+-----o <-- LED |

| | | | | | ||

| − | + | 2.2k R +----|<|-----+ <-- Diode | |

The LED may be placed above the ceiling at one side of the fitting, so that its light is visible at one edge of the lamp that has failed. | The LED may be placed above the ceiling at one side of the fitting, so that its light is visible at one edge of the lamp that has failed. | ||

| Line 215: | Line 226: | ||

=More Information= | =More Information= | ||

==Avoid Hf Transformers== | ==Avoid Hf Transformers== | ||

| − | A minority of lower cost electronic transformers use a very high switching frequency, causing significant losses on even quite short [[Cables|cables]]. Such transformers are unusable for long [[Cables|cable]] runs. | + | A minority of lower cost electronic transformers use a very high switching frequency, causing significant losses on even quite short [[Cables|cables]]. Such transformers are unusable for long [[Cables|cable]] runs. 50Hz iron core transformers (electromagnetic rather than electronic) work with any length of wire. |

==Balancing Voltage Drop== | ==Balancing Voltage Drop== | ||

| − | + | Its recommended to ensure all bulbs see the same voltage. Small variations in voltage have a big effect on bulb brightness, [[Lamp Life|life expectancy]] and colour temperature, so voltage mismatch leads to a poor overall appearance. | |

| − | + | When running a set of lamps all from one over-12v transformer, the voltage drop should be equalised for each bulb. The simplest way to do this is usually to use equal [[cable]] lengths and equal loads on each cable. | |

| − | + | Where unequal lengths are needed or [[cable]] loads vary, the cross sectional area of each cable can sometimes be chosen to give matching voltage drops for each lamp. Thus short runs would use thinner cable than longer runs. | |

| + | Where the lamps are run on more than one transformer, its often possible to run nearby bulbs on a standard transformer with no mods, and the further away ones on the custom setup. | ||

=See Also= | =See Also= | ||

| Line 234: | Line 246: | ||

[[Category:Lighting]] | [[Category:Lighting]] | ||

[[Category:Electrical]] | [[Category:Electrical]] | ||

| + | [[Category:Low Voltage]] | ||

Latest revision as of 09:49, 10 May 2013

Low voltage halogens can be run on long cables if there is a good reason to do so, but long cables introduce significant voltage drop, and this issue must be addressed one way or another.

Ignoring the voltage drop issue results in bulbs running at well below intended light output, and well below their usual level of energy efficiency.

If voltage drop differs between bulbs it also results in uneven lighting appearance and differences in colour temperature. This does not make a lighting installation look good or perform well.

The options

- Avoid the Issue Entirely

- place transformer close to bulb

- don't use very high frequency transformers with more than a couple of feet of cable

- Minimise voltage drop

- Increase transformer output voltage

- Oversize toroidal transformer

- 15v transformer

- Rewinding

- Wave shaping

- Sidestep the issue

- Series bulbs

- 24v bulbs

Avoid the Issue Entirely

The voltage drop problem only occurs wth low voltage high power consumption lamps on long cable runs. Changing to any of the following would remove the cable issue:

- mains voltage halogen

- any other mains voltage lighting

- 12v CFL Lamps

- 12v Fluorescent Lighting

However in some cases 12v lighting is wanted, and when long cable runs are involved it is an issue that can be worked around in various possible ways.

Minimise Voltage Drop

Thick Cable

This is the option most often chosen to minimise V drop, and the simplest. The Cables article gives cable voltage drop for any given current.

However this approach has its limits, and can lead to the need for impractical cable sizes sometimes.

Parallel Cables

Paralleling cable conductors can increase total copper conductor area without making the cable too large to handle.

T&E is a good candidate for parallelling:

- 2.5mm² T&E has a total of 2.5+2.5+1.5 = 6.5mm² of copper area.

- 4mm² T&E has a total of 4+4+1.5 = 9.5mm² of copper area.

Thus 2x T&Es can be used in place of single 6.5mm² or 9.5mm² cables.

Extreme Cables

Very large cables can effectively address voltage drop. The prime candidates are:

- Very large stranded cable as used by supply utilities, and cable for arc welders, jumpleads, etc

- Copper water pipe with soldered joints

- Steel cable could be used in principle, but requires around 10x the cross sectional area of copper for the same voltage drop.

When used, such megaconductors are often made a feature of. (With a little ingenuity a water valve in the pipe could even be made to turn the lights off.)

Increase Transformer Output Voltage

Increasing transformer output voltage to offset cable V_drop is another option if you're able to alter the transformer output voltage. There are a few ways to do this.

Oversize Toroidal Transformer

Toroidal transformers are unregulated, and loading at below rated power causes an increase in voltage output. We can thus increase voltage output by using a transformer rated at a higher power than the load it will run.

Measuring output voltage off-load will show how much V_out rises with no load. V_out_rise is inversely proportional to load, meaning for example half rated load will produce half the voltage rise.

V out |

| .

| '.

| '.

| '.

rated | '.

|

|

|

|

|

|

|

0 |_______________

0 rated Load ->

Voltage output vs load for

non-electronic transformers

This trick doesn't work with electronic transformers.

15v Transformer

15v rectangular transformers are widely available from electronic component suppliers. These are larger than the equivalent toroidals. These supply the necessary 12v plus a 3v margin. Part of the 3v not needed is lost in cable drop, the rest is lost by any of:

- removing turns from the transformer

- changing transformer mains tapping

- an added voltage dropper

Note that these transformers are designed to be built into equipment, and generally have no fusing, no overheat cutout, and bare live terminals. They should be bolted into a box (earthed if metal), ventilated if plastic, with suitable fuses on both mains and secondary sides.

These transformers exhibit the same deregulation as toroidals, so any voltage measurements should be taken with the same load as will be used permanently.

To ensure transformer current rating is sufficient, transformer rated power (in watts) should be 25% (or more) above total connected lamp load.

Fuses for 12v/15v equipment transformers:

- Load current (A) = attached lamp power (watts) / 12v.

- Secondary fuse = Load current x apx 1.3 - 1.5

- Primary fuse: 1.5A

- Both fuses need to be time delay (T) types. These have a spring-like interior construction.

Remove Turns

Removing turns from the transformer secondary reduces voltage output. 4 turns per volt is typical for such mains transfomers. Toroidals can only be turn altered when their centre isn't glued, and gluing is the most popular way to make them. Look for one with a central bolt, discs and rubber pads instead. Never overtighten the central bolt, its easy to ruin toroidals this way, they aren't at all robust in this respect.

Tap changing

Some mains transformers, mostly old ones, have taps on the primary side for more than one mains voltage. (It was once common to see taps for 200,220,240,250v.) When the taps include 250v, this can be used instead of 240v to reduce V_out to 240/250 x 15v = 14.4v.

Using a 12v transformer on a tap of below 230v is not recommended, if mains voltage goes up some it can overheat.

Voltage Dropper

This option comes with issues, but is usually necessary with 15v transformers.

A resistor makes a simple dropper, but the high power dissipation makes for a waste of power and money. Dropping 3v with a resistor reduces energy efficiency by 25%, and can add a lot to the electricity bill over the years. Resistor droppers are defintely not recommended.

Power resistors also run very hot, and suitable care is needed to ensure flammable materials can not come into contact.

Chokes (inductors) make much better droppers, without the heat, run cost and fire problems of resistors. However the calculations required to pick the right choke are more complex, requiring 2 dimensional maths.

When using droppers, each lamp should have its own dropper, otherwise normal lamp failures will cause overvoltage and additional lamp failures.

Boost Winding

Toroidal Transformers are easier to tweak than electronic transformers. One only need add some more copper wire turns onto the transformer, and connect this extra winding in series with the existing output winding to give a voltage increase.

Enamelled copper wire of the same (or larger) size as the output winding already uses should be used to maintain the transformer temp rating and avoid significantly reducing heat dissipation ability.

When the extra winding is connected it will either reduce or increase the V output. If its reduced, just swap the connections of the extra winding round.

4 turns per volt is typical for mains transformers. When measuring V_out, bear in mind that V_out varies significantly depending on load for wound transformers, so the intended bulbs should be used as a load when measuring V_out.

Many toroidal transformers are partly potted to reduce the chance of buzz. These can't be rewound, you need to use a non-potted transformer. These use 2 metal discs, one on top and one underneath to bolt the transformer in place. Rubber pads insulate and spread the load under the discs. When doing up the central fixing bolt afterwards, go easy with the pressure. Overtightening is a cause of toroidal failure, and the extra winding will reduce the amount of force the toroidal structure can withstand.

It is not stictly necessary to use any central bolt fixing with toroidals, the transformer can just be laid in place if it will never be moved, if preferred. When doing this, best sit it on rubber feet to avoid the possibility of hum or buzz.

Wave Shaping

Another way to compensate for V drop is to use a rectifier and capacitor to increase the rms output.

_____

| |

o-------------|~ +|------+-------------o

| | |

| | | +

to | BR | --- to

transformer | | --- lamps

| | |

| | |

o-------------|~ -|------+-------------o

|_____|

Bridge Capacitor

Rectifier

The transformer output is fed through a bridge rectifier, to a reservoir capacitor, and then to the light bulbs. The reservoir capacitor increases rms output by widening the wave shape of the waveform.

This technique should only be applied to non-electronic transformers, ie toroidals and rectangular iron core transformers.

The bridge rectifier's current rating needs to be well above the rms lamp current to deal with peaks and starting surge. Starting current is limited by transformer resistance & lamp resistance, and is typically in the region of 5x run current.

You'll need a true rms reading voltmeter to set this up accurately. It is also possible to set it up approximately by comparing by eye one lamp on a very short cable run direct from the transformer next to another identical lamp on the full length of cable you'll use fed via the wave shaper.

The larger the capacitor, the more rms voltage boost occurs. Transformer power rating should be 50% higher than the lamps it will run. The size of capacitor used is much smaller than those used as PSU reservoirs, as the aim is just to extend the peak a little rather than provide near peak voltage for a whole half cycle.

Schottky diodes need to be used rather than cheaper silicon diodes to keep voltage drop down. Don't be tempted by cheaper non-schottkies, you would pay the difference in power use many times over each year.

This method introduces about a total 0.8v drop in the 2 conducting schottky diodes, resulting in an energy efficiency reduction of apx 6-7%. Expect the diodes to run hot.

50w of 12v bulbs need around 33uF to increase mean V_out by 1%, so restoring the 0.8v lost in the rectifier takes around 220uF. Required capacitor size is proportional to lamp power load. Capacitors should be 25v rated (higher is ok).

Tweaking an Electronic Transformer

These require some electronics knowledge to modify, so are outside the skill set of most DIYers. For those with the necessary skills, a diode in right place in the voltage regulation feedback path can add 0.6v to the output, 2 diodes can add 1.2v.

Sidestep the Issue

Series Bulbs

Running 2x 12v bulbs in series on 24v reduces the voltage drop problem by a factor of 4. It halves the current draw of the pair, halving voltage drop, plus a given absolute amount of voltage drop has only half as much effect on each lamp's operating voltage.

This approach makes cable runs 4x as long practical. The downsides are:

- When one bulb blows, both go out.

- The 2 bulbs must always be the same wattage as each other (fitting 2 different wattage lamps would cause one lamp to fail)

Extinguishing of bulbs in pairs can be a problem when only 2 bulbs are used, but much less so where more than one pair of bulbs are in use.

Dead Bulb Indicator

A simple dead bulb indicator can be wired across each light fitting to show which needs replacement. This is made from a bicolour LED and a 2.2k resistor in series.

o----/\/\----------|>|----------o

|<|

2.2k

The LED lights up when the bulb its wired across dies.

A cheaper single colour LED can be used with a diode across it, wired in reversed parallel. Never omit the diode.

o----/\/\-----+----|>|-----+-----o <-- LED

| |

2.2k R +----|<|-----+ <-- Diode

The LED may be placed above the ceiling at one side of the fitting, so that its light is visible at one edge of the lamp that has failed.

The LEDs are much more visible if ultrabright LEDs are used, and will then be readily seen in daylight, even when recessed behind the halogen bulb.

24v Bulbs

24v bulbs use half as much current for a given power, and the same absolute amount of voltage drop only makes half as much difference as with 12v bulbs. Thus 24v bulbs improve the voltage drop situation by a factor of 4.

The downside is that using 24v bulbs will limit you to using truck lightbulbs and other 24v bulbs, making this a far from ideal choice in most cases.

Note that nominally 24v truck bulbs are in reality 27v rated, and will need a 27v rms supply to give full light output.

More Information

Avoid Hf Transformers

A minority of lower cost electronic transformers use a very high switching frequency, causing significant losses on even quite short cables. Such transformers are unusable for long cable runs. 50Hz iron core transformers (electromagnetic rather than electronic) work with any length of wire.

Balancing Voltage Drop

Its recommended to ensure all bulbs see the same voltage. Small variations in voltage have a big effect on bulb brightness, life expectancy and colour temperature, so voltage mismatch leads to a poor overall appearance.

When running a set of lamps all from one over-12v transformer, the voltage drop should be equalised for each bulb. The simplest way to do this is usually to use equal cable lengths and equal loads on each cable.

Where unequal lengths are needed or cable loads vary, the cross sectional area of each cable can sometimes be chosen to give matching voltage drops for each lamp. Thus short runs would use thinner cable than longer runs.

Where the lamps are run on more than one transformer, its often possible to run nearby bulbs on a standard transformer with no mods, and the further away ones on the custom setup.