Difference between revisions of "Holesaw"

(asstd) |

|||

| (2 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

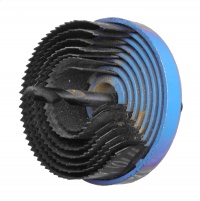

| − | [[image:Holesaw_0455-6.jpg|391px]] | + | [[image:Holesaw_0455-6.jpg|391px|right]] |

Holesaw choice and tips on use. | Holesaw choice and tips on use. | ||

| Line 9: | Line 9: | ||

===Standard holesaw=== | ===Standard holesaw=== | ||

| − | As seen above, | + | As seen above, holesaws are usually a cylinder shape with [[saw]] teeth on the open end. A central pilot [[drill bit]] is fitted. These usually come in sets with sizes optimised for electricians or plumbers. |

These can drill to almost the depth of the holesaw. For very thick materials, if the saw is withdrawn and the cut centre of the wood chopped out, it can then drill the same depth again. | These can drill to almost the depth of the holesaw. For very thick materials, if the saw is withdrawn and the cut centre of the wood chopped out, it can then drill the same depth again. | ||

| − | Holesaws come in carbon steel, bimetal and HSS. All can drill wood and plastic, and the HSS ones can also drill metal. | + | Holesaws come in carbon steel, bimetal and HSS (in ascending order of durability). All can drill wood and plastic, and the HSS ones can also drill metal. |

With Starrett cutters and all systems which are compatible (e.g. Bosch and Sandvik), the arbor and the cutter are separate, and there are two sizes or arbor and two types of [[Drill bit|pilot drill]]. | With Starrett cutters and all systems which are compatible (e.g. Bosch and Sandvik), the arbor and the cutter are separate, and there are two sizes or arbor and two types of [[Drill bit|pilot drill]]. | ||

| − | |||

===Interchangeable blade holesaw=== | ===Interchangeable blade holesaw=== | ||

| − | [[image:Holesaw 1550-6.jpg| | + | [[image:Holesaw 1550-6.jpg|right|200px]] |

These comprise a cast metal base with circular grooves, and a bent [[saw]]blade to fit each groove. To use them, one blade is clipped into the base. They also have a central pilot [[drill bit]]. | These comprise a cast metal base with circular grooves, and a bent [[saw]]blade to fit each groove. To use them, one blade is clipped into the base. They also have a central pilot [[drill bit]]. | ||

| − | These are very poor performers, though just about workable with care. They also don't last long, expect half a dozen holes per blade size if you're consistently careful. Often they | + | These are very poor performers, though just about workable with care. They also don't last long, expect half a dozen holes per blade size if you're consistently careful. Often they don't last that long. |

The [[saw]]blades are weak and have little support, and very gentle pressure must be used at all times. A momentary application of moderate force and they break, damaging the workpiece. They also don't tolerate fast rotational speed, since the [[saw]]blade is poorly supported. | The [[saw]]blades are weak and have little support, and very gentle pressure must be used at all times. A momentary application of moderate force and they break, damaging the workpiece. They also don't tolerate fast rotational speed, since the [[saw]]blade is poorly supported. | ||

| − | These need to be withdrawn to clear debris regularly during use. They can only drill to the depth of the blade protrusion, so thicker items like | + | These need to be withdrawn to clear debris regularly during use. They can only drill to the depth of the blade protrusion, so thicker items like [[door]]s need to be drilled from both sides to make the hole. Stop just short of full depth penetration, or the [[metal]] casting scrapes & scratches the workpiece. |

===Core drill=== | ===Core drill=== | ||

These have an abrasive cutting edge rather than [[saw]] teeth, and are used on masonry. Most used in DIY are designed to work dry, but there are also ones that need a flow of [[water]] to cool and clear debris. | These have an abrasive cutting edge rather than [[saw]] teeth, and are used on masonry. Most used in DIY are designed to work dry, but there are also ones that need a flow of [[water]] to cool and clear debris. | ||

| − | Due to the hard nature of masonry, a snag | + | Due to the hard nature of masonry, a snag can cause injury, and core drills should be used with a drill that has a safety clutch. |

| − | Holesaws may use carbide or diamond abrasive. Diamond is used on tiles. | + | Holesaws may use carbide or diamond abrasive. Diamond is used on tiles. Diamond is harder but TC is much better value for money, ie cost is less per hole. |

| − | Hammer action is not usually used with a diamond core drill or an [[Drill bit|abrasive tile drill]]. There are core drills available that are designed to be used with hammer action, but | + | Hammer action is not usually used with a diamond core drill or an [[Drill bit|abrasive tile drill]]. There are core drills available that are designed to be used with hammer action, but most are '''not''' suitable for this, and usually it isn't needed. |

| Line 44: | Line 43: | ||

===Drill bits=== | ===Drill bits=== | ||

| − | [[image:Augers_0071-5.JPG| | + | [[image:Augers_0071-5.JPG|right|200px]] |

Some drill bits are also used for large holes. These include | Some drill bits are also used for large holes. These include | ||

| Line 51: | Line 50: | ||

* [[Drill bit|Auger]] - very neat, but drilling angle not correctable during work. Can also be used in a hand brace or impact driver. | * [[Drill bit|Auger]] - very neat, but drilling angle not correctable during work. Can also be used in a hand brace or impact driver. | ||

* [[Drill bit|MAD bit]] - wander readily, can correct misaligned holes | * [[Drill bit|MAD bit]] - wander readily, can correct misaligned holes | ||

| − | * [[Drill bit|Cone bit]] - these make large holes in thin [[Sheet Materials|sheet material]], mainly plastic & metal. Available in continuous and stepped size types. Tidy the hole up by drilling from the other side a little too. | + | * [[Drill bit|Cone bit]] - these make large holes in thin [[Sheet Materials|sheet material]], mainly [[plastic]] & [[metal]]. Available in continuous and stepped size types. Tidy the hole up by drilling from the other side a little too. |

For more detailed info on these drill bits, see [[Drill bit]] | For more detailed info on these drill bits, see [[Drill bit]] | ||

| Line 62: | Line 61: | ||

Typically designed for large holes (commonly around 30mm to 150mm) in | Typically designed for large holes (commonly around 30mm to 150mm) in | ||

[[Sheet Materials|thin soft materials]], primarily plasterboard. Limited depth of cut (around 20-30mm) so more often useful for [[Sheet Materials|sheet materials]], eg: cutting [[Lighting|downlighter]] holes in a plasterboard ceiling. | [[Sheet Materials|thin soft materials]], primarily plasterboard. Limited depth of cut (around 20-30mm) so more often useful for [[Sheet Materials|sheet materials]], eg: cutting [[Lighting|downlighter]] holes in a plasterboard ceiling. | ||

| + | |||

| + | Use a pillar drill wherever possible. These can be quite troublesome to use in a hand drill, the larger the hole the more of a problem they're liable to be. | ||

| Line 69: | Line 70: | ||

===Router=== | ===Router=== | ||

| − | A router can be used to make very large holes in [[Sheet Materials|sheet material]]. | + | A [[router]] can be used to make very large holes in [[Sheet Materials|sheet material]]. |

| + | |||

| + | To make a round hole the router is pivoted around a point where it's held with a nail etc. | ||

===Punch=== | ===Punch=== | ||

| − | Punches can be used with sheet metals and non-brittle plastics. | + | Punches can be used with sheet metals and non-brittle plastics. Some can cause significant distortion of sheet metal. |

| Line 83: | Line 86: | ||

* In use the drill needs to be kept straight, or the hole will be misshapen | * In use the drill needs to be kept straight, or the hole will be misshapen | ||

* Keep pressure fairly gentle, or the [[saw]] will snag | * Keep pressure fairly gentle, or the [[saw]] will snag | ||

| − | * The final hole size often doesn't match the holesaw size. If size matters, test first on | + | * The final hole size often doesn't match the holesaw size due to imperfect shape & centering. If size matters, test first on scrap wood |

* If the pilot drill is blunt, pre-drill a centre hole with another [[drill bit]] | * If the pilot drill is blunt, pre-drill a centre hole with another [[drill bit]] | ||

* To enlarge an existing hole, just fill the hole first. Jam a piece of round timber into it, or attach a bit of [[Sheet Materials|sheet wood]] under the old hole | * To enlarge an existing hole, just fill the hole first. Jam a piece of round timber into it, or attach a bit of [[Sheet Materials|sheet wood]] under the old hole | ||

| Line 89: | Line 92: | ||

* Core drills are for masonry only | * Core drills are for masonry only | ||

* When cutting thin or flexible material, [[clamp]] some wood to the back of it | * When cutting thin or flexible material, [[clamp]] some wood to the back of it | ||

| − | * If you need to cut out a disc with no centre hole, cut a disc from some scrap | + | * If you need to cut out a disc with no centre hole, cut a disc from some scrap & fix it onto the material you wish to drill. Now the holesaw sits over the disc without the pilot bit needing to protrude. This way the first disc controls the holesaw's position instead of the pilot bit. |

==Safety== | ==Safety== | ||

| − | The main [[safety]] issue with holesaws is the tendency to snag. When this happens, the drill is yanked round forcefully, potentially causing a wrist injury. | + | The main [[safety]] issue with holesaws is the tendency to snag. When this happens, the drill is yanked round forcefully, potentially causing a wrist injury. It's best to use a drill with a safety clutch, this is designed to slip in such situations, minimising the likelihood of injury. Nearly all cordless drills have this feature. Also pay clos attention to the angle you're holding the drill, keeping the holesaw centred in the hole rather than angling over to one side, which tends to happen without noticing. |

| − | Where a holesaw is used in a drill with no safety clutch, take care not to let | + | Where a holesaw is used in a drill with no safety clutch, take extra care not to let the drill wander to one side during drilling, and keep drilling speed and force low. Less than careful use with no safety clutch can lead to hospital. |

Latest revision as of 03:19, 4 September 2017

Holesaw choice and tips on use.

Holesaw types

There are 2 main types of holesaw used in DIY, and some other tools that also make medium & large holes.

Standard holesaw

As seen above, holesaws are usually a cylinder shape with saw teeth on the open end. A central pilot drill bit is fitted. These usually come in sets with sizes optimised for electricians or plumbers.

These can drill to almost the depth of the holesaw. For very thick materials, if the saw is withdrawn and the cut centre of the wood chopped out, it can then drill the same depth again.

Holesaws come in carbon steel, bimetal and HSS (in ascending order of durability). All can drill wood and plastic, and the HSS ones can also drill metal.

With Starrett cutters and all systems which are compatible (e.g. Bosch and Sandvik), the arbor and the cutter are separate, and there are two sizes or arbor and two types of pilot drill.

Interchangeable blade holesaw

These comprise a cast metal base with circular grooves, and a bent sawblade to fit each groove. To use them, one blade is clipped into the base. They also have a central pilot drill bit.

These are very poor performers, though just about workable with care. They also don't last long, expect half a dozen holes per blade size if you're consistently careful. Often they don't last that long.

The sawblades are weak and have little support, and very gentle pressure must be used at all times. A momentary application of moderate force and they break, damaging the workpiece. They also don't tolerate fast rotational speed, since the sawblade is poorly supported.

These need to be withdrawn to clear debris regularly during use. They can only drill to the depth of the blade protrusion, so thicker items like doors need to be drilled from both sides to make the hole. Stop just short of full depth penetration, or the metal casting scrapes & scratches the workpiece.

Core drill

These have an abrasive cutting edge rather than saw teeth, and are used on masonry. Most used in DIY are designed to work dry, but there are also ones that need a flow of water to cool and clear debris.

Due to the hard nature of masonry, a snag can cause injury, and core drills should be used with a drill that has a safety clutch.

Holesaws may use carbide or diamond abrasive. Diamond is used on tiles. Diamond is harder but TC is much better value for money, ie cost is less per hole.

Hammer action is not usually used with a diamond core drill or an abrasive tile drill. There are core drills available that are designed to be used with hammer action, but most are not suitable for this, and usually it isn't needed.

Pilotless holesaw

Holesaws with no pilot bit are occasionally seen. These are for use on a pillar drill with a clamped workpiece. They're not usable in hand held tools.

Drill bits

Some drill bits are also used for large holes. These include

- Flat bit - tend to produce a messy edge to the hole.

- adjustable flat bit - adjustable hole width

- Auger - very neat, but drilling angle not correctable during work. Can also be used in a hand brace or impact driver.

- MAD bit - wander readily, can correct misaligned holes

- Cone bit - these make large holes in thin sheet material, mainly plastic & metal. Available in continuous and stepped size types. Tidy the hole up by drilling from the other side a little too.

For more detailed info on these drill bits, see Drill bit

Adjustable holesaw

These comprise a rotating arm with one or two moveable cutting blades.

Typically designed for large holes (commonly around 30mm to 150mm) in thin soft materials, primarily plasterboard. Limited depth of cut (around 20-30mm) so more often useful for sheet materials, eg: cutting downlighter holes in a plasterboard ceiling.

Use a pillar drill wherever possible. These can be quite troublesome to use in a hand drill, the larger the hole the more of a problem they're liable to be.

Saws

Jigsaws and handsaws are often used for very large holes.

Router

A router can be used to make very large holes in sheet material.

To make a round hole the router is pivoted around a point where it's held with a nail etc.

Punch

Punches can be used with sheet metals and non-brittle plastics. Some can cause significant distortion of sheet metal.

Nibbler

Nibblers make holes of almost any shape in sheet metal. A file, die grinder or angle grinder is used to clean the hole up.

Use

- In use the drill needs to be kept straight, or the hole will be misshapen

- Keep pressure fairly gentle, or the saw will snag

- The final hole size often doesn't match the holesaw size due to imperfect shape & centering. If size matters, test first on scrap wood

- If the pilot drill is blunt, pre-drill a centre hole with another drill bit

- To enlarge an existing hole, just fill the hole first. Jam a piece of round timber into it, or attach a bit of sheet wood under the old hole

- Holesaws are for use on wood, plastic, and in many cases metal. They're not for masonry

- Core drills are for masonry only

- When cutting thin or flexible material, clamp some wood to the back of it

- If you need to cut out a disc with no centre hole, cut a disc from some scrap & fix it onto the material you wish to drill. Now the holesaw sits over the disc without the pilot bit needing to protrude. This way the first disc controls the holesaw's position instead of the pilot bit.

Safety

The main safety issue with holesaws is the tendency to snag. When this happens, the drill is yanked round forcefully, potentially causing a wrist injury. It's best to use a drill with a safety clutch, this is designed to slip in such situations, minimising the likelihood of injury. Nearly all cordless drills have this feature. Also pay clos attention to the angle you're holding the drill, keeping the holesaw centred in the hole rather than angling over to one side, which tends to happen without noticing.

Where a holesaw is used in a drill with no safety clutch, take extra care not to let the drill wander to one side during drilling, and keep drilling speed and force low. Less than careful use with no safety clutch can lead to hospital.