Difference between revisions of "Monobloc Air to Water small"

m (Rename and minor changes to better fit the style of other articles) |

m (updated) |

||

| (6 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

== Monobloc Air Source Heat Pump (ASHP) == | == Monobloc Air Source Heat Pump (ASHP) == | ||

| − | This article describes a project to replacing a gas combination boiler with a heat pump to run radiators directly. | + | This article describes a project to replacing a gas combination boiler with a heat pump to run radiators directly. This is only possible under certain circumstances, see http://wiki.diyfaq.org.uk/index.php/Replacing_a_gas_combination_boiler_with_a_heat_pump |

== Introduction == | == Introduction == | ||

| Line 33: | Line 33: | ||

==== Step 4. Inside plumbing ==== | ==== Step 4. Inside plumbing ==== | ||

| − | The only water-side bit | + | The only water-side bit within the boiler is the flow switch on the output, I have to fit everything else inside the flat. I strip the old gas combi to get the expansion disc, the 3/4-inch ball-valves and the gauges. I board the inside of the bathroom cupboard, about 600 wide and 1800 high, in the space left when the bath was replaced by the shower cubicle. My old circulating pipes run floor to ceiling, an overhead pair to lounge and kitchen, underfloor to bedroom and bathroom, a vent tap at the top. I mount the expansion cylinder at head level, using the metalwork from the combi. Below goes the pump from the feed and the magnetic filter in the return, with their isolating valves. The old temperature and pressure gauges I mount between them on a spur-pipe to the expansion disc. I file slots in a copper pipe stub to take the retaining clip for the pressure sensor and ram it in with PTFE. Beneath I fit the instant hot water heater. At the bottom go all the service and check valves, drain points and piping. I fit junction boxes in the spare space. The rig uses the whole board and I hide the lot behind a false door panel. I fit a thermostatic shower-bar in the cubicle, I originally wired for overhead pull-switches for the ASHP and water heater, but I don't fit these. The DHW is on an old cooker switch on the mounting board and the ASHP must be always on, so I wire direct from the MCB to the isolator awitch on the unit. |

==== Step-5. Outside. ==== | ==== Step-5. Outside. ==== | ||

| Line 47: | Line 47: | ||

[[File:ASHP internal.jpg|thumb|unit internals]] | [[File:ASHP internal.jpg|thumb|unit internals]] | ||

[[File:ASHP circuit board.JPG|thumb|unit circuit board]] | [[File:ASHP circuit board.JPG|thumb|unit circuit board]] | ||

| − | It powers up into standby, the screen shows the outside temperature. Push to run, shows the inlet and outlet temeratures. No trip of the 10A MCB, so that's fine. It takes 5 minutes to start warming but once stabilised all | + | It powers up into standby, the screen shows the outside temperature. Push to run, shows the inlet and outlet temeratures. No trip of the 10A MCB, so that's fine. It takes 5 minutes to start warming but once stabilised all radiators are hand-hot, Factory settings give me readings of 39-42 before it switches to standby, it kicks back in at 39-39, runs up to 41-43, kicks out, and so on. Cycles about every minute on/off. This on one warmish October day when outside temperature reads 17 rising to 20 as the sun hits the greenhouse roof. I turn the pump down to 2nd position, then down to 1 but no flow fault results. I close the three TRVs: no problem. I close the towel rail which is my nearest by-pass, leaving only the 1m lounge radiator: this gives a flow fault. I turn the pump up to 3 but it doesn't help. Opening a TRV clears it and the ASHP self-resets and runs again. The rail has big tubes and is closest to the pump. I can close it if the TRVs are open so I'll just leave it always open for now as the bathroom is central in the flat and warms the central lobby. |

=== Conclusion. === | === Conclusion. === | ||

| Line 64: | Line 64: | ||

The towel rail and small radiator left on full flow, the three others had their TRVs set to 2. The bedroom rad got quite cool during the sunny periods. The system in/out readings near the beginning and end of the test were cycling as usual, between 39-39 and 41-45. Max differential about 6 degrees, min zero. | The towel rail and small radiator left on full flow, the three others had their TRVs set to 2. The bedroom rad got quite cool during the sunny periods. The system in/out readings near the beginning and end of the test were cycling as usual, between 39-39 and 41-45. Max differential about 6 degrees, min zero. | ||

| − | Readings taken at noon both days. Outside temperature reported by the compressor commenced at 11 degrees, dropped to 4 overnight according the the BBC, rose to 12 the following noon. Inside temperature by a thermocouple digital thermometer in the central lobby at about waist height, not touching the walls, commenced at 20, rose to 21 and stayed level all the final morning, just hitting 22 before the end when the sun hit the windows. Energy consumption for the day was 26kWh. | + | Readings taken at noon both days. Outside temperature reported by the compressor commenced at 11 degrees, dropped to 4 overnight according the the BBC, rose to 12 the following noon. Inside temperature by a thermocouple digital thermometer in the central lobby at about waist height, not touching the walls, commenced at 20, rose to 21 and stayed level all the final morning, just hitting 22 before the end when the sun hit the windows. Energy consumption for the day was 26kWh. So 26kWhr in 24 hrs is similar to running a 1kW heater continuously all day, as expected from the unit specification. |

| − | + | '''Test Repeated''' a few days later with similar weather conditions, ambient started at 11 degrees, dropped to a predicted 3 overnight, up to 12 next noon or 14 with the sun out. Used 28kWhr this time. at 30p/unit that's an all-over warm flat for under £9 a day. | |

| − | ===== | + | ===== After a Winter ===== |

| − | + | One year onward, the single male occupant is happy with the system and has never had to use the panel heater to top up the flat's heat. Project is a success!. | |

| − | |||

| − | |||

[[Category:Heating]] | [[Category:Heating]] | ||

[[Category:Air Conditioning and Heat Pumps]] | [[Category:Air Conditioning and Heat Pumps]] | ||

Latest revision as of 16:23, 6 December 2022

Monobloc Air Source Heat Pump (ASHP)

This article describes a project to replacing a gas combination boiler with a heat pump to run radiators directly. This is only possible under certain circumstances, see http://wiki.diyfaq.org.uk/index.php/Replacing_a_gas_combination_boiler_with_a_heat_pump

Introduction

Yes, you only need plumbing skills to replace your gas combi with an ASHP, if you use a monobloc unit.

This is a refurbishment of a 65 sq.m. ground floor 1-bed flat. It's 1980's era built, block with thermal cavity batts and thermalite inner wall and has another flat above, so not too much heat needed. Just a lounge, bedroom, kitchen and bathroom. The floors are screeded block and beam over a cavity. Kitchen, lobby and bathroom have floor tiles, the lounge has MDF laminate board, only the bedroom is carpeted. There's a lot of thermal capacity in that 65 sq.m. of tiling, so a bit of temperature cycling won't matter. The 20kW gas combi boiler on the bathroom wall used to cycle a lot and was tuned down to 50 degrees too. No bath here, the DHW heater on the combi just ran the shower and an occasional washing up bowl. The flat is over-radiatored with 4-off doubles totalling 5m long, so 10m by 900 high is 9 sq.m. of radiating surface, so all rooms stay at about equal temperature, given the insulated outer shell and the uninsulated internal studding. The door between the lounge and kitchen is often left open too.

So I decide to get rid of the gas forever. The DHW for shower, sink and basin can be done by an instant electric 9kW multi-point. Unlikely that they'll all be on at the same time. No water storage needed. So what's feasible for the CH here? This is West of England, 20 miles from the sea. A steady climate, we see about half-inch or less of snow maybe for a day or two, temperature rarely drops below -5. Cold snaps only last a day or two. It seems a good place for an ASHP. For cold snaps an electric panel in the lounge can add extra heat ad lib.

Step-1 Research.

Minimal practical information on the internet, only general descriptions. At first it looks like I am swapping one closed-shop trade-union for another, Gas-safe for F-gas. Both tight-lipped and opposed to all DIY. Installers are trying to sell me a split system with a buffer tank in the house. I don't want any tanks, no room in the flat. Then AHA! there's a DIY loop-hole called a monobloc system. It's just a large refrigerator, self-contained, no F-Gas fitting needed unless it breaks or needs a top-up. Refrigerators go on for years and then you just replace them.

Next I looked for a supplier/fitter. Here lies the real problem. The accredited MCS installers aren't interested in fitting a monobloc and won't touch a DIY installation, they want to do the whole system themselves and fit as shown in their books, not the way I want. Quotes were enormous. The main work is normal domestic plumbing. So it's to be a DIY job. But major ASHP suppliers won't sell units to individuals, or even qualified plumbers, only to company-trained fitters.

The only available DIY option was the ASHP units advertised on Ebay. Sold by a trader who buys them in from China re-branded as Dream Heatpumps. I find similar units and identical user manuals in several web searches, Swedish and German brands, Firefly was one. I ask the ebay seller about a Dream 5kW ASHP (air to water) unit. He isn't a lot of help, just sells them over the 'phone. No manual available in advance either. So I read a Daikin spec sheet for a similar one. Seems ASHPs are like air-con units, completely different from gas combi units.

Step-2 Design the system.

ASHPs run at about 40 degrees, lower than the 50-55 from a combi. But I already decided I have enough radiation area, 9 sq.m serving 65 sq.m. of floor space. Plus a towel rail too.

First check: water volume needs to be over 20 litres for a small ASHP boiler, I find, or I'd need a buffer tank for which I have no space. so I counted the radiator columns, 268, estimate 0.1 litres each, plus pipework and towel rad. So about 30 litres for the system. Should be OK without a buffer tank. I can add a small one in the return pipe later if the temperature cycles up and down too much. But I will fit an enormous towel-rail in the shower room, just in case.

Second check: flow rate about 12 litres/min. I won't use a check valve and I'll split the radiator load in half, making two 15mm spurs off a 22mm feed, I should be able to push a lot of flow through 268 columns. I bought a cheap pump, put it on the supply side and switched the speed to maximum. The radiator drain point gushed nicely, so I expect it'll be OK. If I need more flow I'll add another by-pass.

Project looking good so far, so I buy the 5kW unit. Cost me about a quarter of the MCS installer's quotes. Cross fingers that I'm not gambling for a loss.

Step 3. It arrives.

First chance to get hands-on information. No maker's data. From the part number I divine that it's probably made in Guangzhou. The wiring diagram is on the back of the cover panel and easy to understand. The enclosed manual only shows a basic fitting example, but it is good for explaining the digital control panel, readings and fault codes.

This ASHP is not a DC-inverter slow-start unit, just a bang-bang on/off compressor about triple the power of a big refrigerator. I see a 30 microfarad capacitor on the compressor. I'll get a current surge, but a 5kW unit is only 5A (1.2kW) running and start current peaks under 10A. So I run 2.5mm TWE cable from the recommended 10A MCB. If it trips I'll fit a type-C curve breaker. I also run cable for a panel heater in the lounge, just in case the 5kW ASHP isn't adequate for deep Winter.

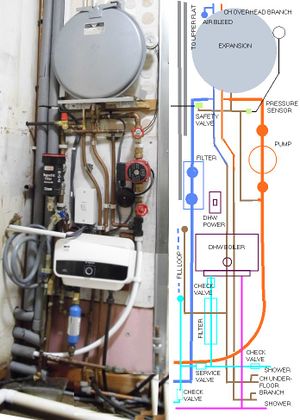

Step 4. Inside plumbing

The only water-side bit within the boiler is the flow switch on the output, I have to fit everything else inside the flat. I strip the old gas combi to get the expansion disc, the 3/4-inch ball-valves and the gauges. I board the inside of the bathroom cupboard, about 600 wide and 1800 high, in the space left when the bath was replaced by the shower cubicle. My old circulating pipes run floor to ceiling, an overhead pair to lounge and kitchen, underfloor to bedroom and bathroom, a vent tap at the top. I mount the expansion cylinder at head level, using the metalwork from the combi. Below goes the pump from the feed and the magnetic filter in the return, with their isolating valves. The old temperature and pressure gauges I mount between them on a spur-pipe to the expansion disc. I file slots in a copper pipe stub to take the retaining clip for the pressure sensor and ram it in with PTFE. Beneath I fit the instant hot water heater. At the bottom go all the service and check valves, drain points and piping. I fit junction boxes in the spare space. The rig uses the whole board and I hide the lot behind a false door panel. I fit a thermostatic shower-bar in the cubicle, I originally wired for overhead pull-switches for the ASHP and water heater, but I don't fit these. The DHW is on an old cooker switch on the mounting board and the ASHP must be always on, so I wire direct from the MCB to the isolator awitch on the unit.

Step-5. Outside.

The ASHP isn't a weather-proof unit. Strange, because it looks like any other outside air-con unit. Luckily I already have a small lean-to greenhouse behind the bedroom to take it. The extra solar gain from the polycarbonate roof will be useful. Must make sure no tomato plants get near the fan. I lay two big paving slabs on a cement base. I ignore the ludicrous space requirements in the manual and place it like I've seen many similar units on commercial premises, about 10 inches behind-space, plenty of frontage. There's a drainage pipe comes with the unit which won't fit properly and I discard: I'm happy for the condensed water to run out over the slabs into the garden gravel. I screw the unit down on its rubber pads, screw the old ball valves into it and run 4m of 22mm PVC barrier pipe along the wall to my entry point. I use two lengths of galvanised 150mm cable tray screwed to the wall above and below the pipes and box them in with 60mm Kingspan Styrozone XPS, which is tough. insulating and waterproof. I run a condit above for the three cables (supply, pump, controller).

Step-6. Controls.

There's a computer board in the ASHP with several sensors for self-protection and monitoring, including the flow switch. The unit controls the water pump and it's an always-on system, so it can self-start in case of frost and overrun for it's de-icing cycles. I was hoping to use the old room thermostat as the main control, but not possible unfortunately. A difference in philosophy between Europe and Japan it seems. Most air-con use a hand-held remote, like a TV set. The only user input here is by the digital panel on the unit. Fortunately that's removable and can be fitted indoors. Removal leaves a grommet hole so I drill the case and put the mains isolating switch over it.

The controller uses an unshielded 3-wire 0.5mm cable and has a connector on a stub. I clip both and fit it indoors instead of the old thermostat, then wire the connector back to the unit with ordinary 1mm TWE cable. That's a 6m run, but the controller seems fine with it. It has a time-switch and a power button for run or standby, but there is no OFF function. You can set water in/out temperature limits but that's seasonal really: it's not good for daily control so I'll have to use TRVs and a by-pass. I'll put the furthest lounge radiator and the towel rail permanently on full flow, that's one on each branch, the other three on TRVs. Curiously, the controller has settings for dehumidify and cooling too! Presumably it's a generic air-con model. Hope nobody accidentally sets the radiators to freeze the flat!

Step-7. Commissioning.

It powers up into standby, the screen shows the outside temperature. Push to run, shows the inlet and outlet temeratures. No trip of the 10A MCB, so that's fine. It takes 5 minutes to start warming but once stabilised all radiators are hand-hot, Factory settings give me readings of 39-42 before it switches to standby, it kicks back in at 39-39, runs up to 41-43, kicks out, and so on. Cycles about every minute on/off. This on one warmish October day when outside temperature reads 17 rising to 20 as the sun hits the greenhouse roof. I turn the pump down to 2nd position, then down to 1 but no flow fault results. I close the three TRVs: no problem. I close the towel rail which is my nearest by-pass, leaving only the 1m lounge radiator: this gives a flow fault. I turn the pump up to 3 but it doesn't help. Opening a TRV clears it and the ASHP self-resets and runs again. The rail has big tubes and is closest to the pump. I can close it if the TRVs are open so I'll just leave it always open for now as the bathroom is central in the flat and warms the central lobby.

Conclusion.

Yes, a DIY ASHP is not a problem to do with basic plumbing and DIY skills. Quite a lot of work though. Drilling holes for the external pipework, building a base and greenhouse for the unit, making up a board of water-side bits and fitting that into a box or cupboard space, running and protecting the external pipes, running the three cables, increasing radiator sizes probably too. I was lucky that I didn't need to change radiators or build a greenhouse and my pipe entry was exactly where the old gas boiler was hung.

I have already run the 22mm water pipes for the upper flat. One day I'll put a table over the first ASHP and mount another on top. They weigh about 70kg, not heavy.

Grumbles

Pity no plumbing firm in my area has enough courage and cash to buy in some monobloc units from Ghuangzhou, as advertised on the china business websites. They could replace a lot of gas boilers in small bungalows or 2-storey flats without needing either GasSafe or F-gas accreditation. Pity too that the big suppliers like Daikin and Mitsubishi won't sell direct to plumbers.

I did have one incident when I was playing with the flow-fault experiment. It once refused to self-correct and I had to go out and flip the main switch off-on to restart it.

Measured Test Results

A 24-hour test done in typical autumn conditions for this area in November. Partly sunny days, low wind. The 65 sq.m. flat was unoccupied and unfurnished, windows closed, curtains open, all internal doors wide open. Some solar gain from 3-4 hours of weak sunshine in the windows and there's a flat above which is well heated.

The towel rail and small radiator left on full flow, the three others had their TRVs set to 2. The bedroom rad got quite cool during the sunny periods. The system in/out readings near the beginning and end of the test were cycling as usual, between 39-39 and 41-45. Max differential about 6 degrees, min zero.

Readings taken at noon both days. Outside temperature reported by the compressor commenced at 11 degrees, dropped to 4 overnight according the the BBC, rose to 12 the following noon. Inside temperature by a thermocouple digital thermometer in the central lobby at about waist height, not touching the walls, commenced at 20, rose to 21 and stayed level all the final morning, just hitting 22 before the end when the sun hit the windows. Energy consumption for the day was 26kWh. So 26kWhr in 24 hrs is similar to running a 1kW heater continuously all day, as expected from the unit specification.

Test Repeated a few days later with similar weather conditions, ambient started at 11 degrees, dropped to a predicted 3 overnight, up to 12 next noon or 14 with the sun out. Used 28kWhr this time. at 30p/unit that's an all-over warm flat for under £9 a day.

After a Winter

One year onward, the single male occupant is happy with the system and has never had to use the panel heater to top up the flat's heat. Project is a success!.