Oscillating tools

Introduction

The oscillating tool, is a concept that was originally made popular by the German manufacturer Fein with their Multimaster range of tools. In recent years, a number of similar tools based on the multimaster concept have become available. This article serves not only as a FAQ for this particular class of tool, it also documents the level of interoperability between the blades and accessories for the various makes.

What is it?

Its a small versatile tool designed to perform a wide range of tasks. They can be used for cutting, sanding, rasping, polishing, scraping and a number of other tasks. They make very effective tools for performing awkward cutting operations that are almost impossible with any other tool.

How does it work?

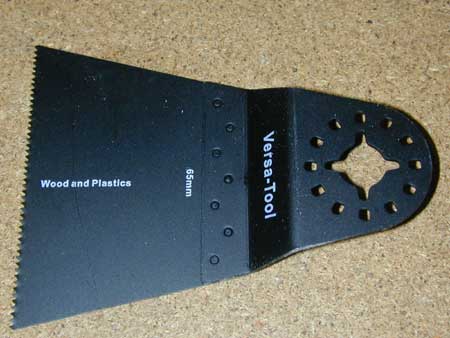

An oscillating tool, looks a little reminiscent of a detail sander, and in fact they do make very good detail sanders. However that is where the similarity ends. Rather than having a fixed sanding pad that orbits, they have a tool attachment post. The various tools are then firmly bolted or clipped to the post. When running the tool post rotates a very small amount in alternating directions, at a very high frequency (typically 20,000 oscillations per minute). Its this oscillation that does the actual work. The end of a saw blade for example will swing back and forth by a couple of millimetres. With its fine teeth, this is enough to cut any rigidly held material it comes into contact with. An abrasive will similarly work back and forth over a surface.

What can it do?

One of the unique abilities of this type of tool is the way in which it can cut. Equipped with the appropriate blade it can simply plunge into the surface of the material that is being cut, without touching or damaging anything adjacent to the thing being cut. Unlike for example a chisel, the cut also leave a very fine kerf. This makes it ideal for a number of jobs:

- Cutting floorboards prior to lifting - precise neat cuts can be plunged into a board directly above a joist with no risk to pipes or cables under the floor.

- Flush cutting; many of the blades include an offset of "crank" that enables them to cut flash with a surface. This is ideal for cropping pipes against a wall, or undercutting a door frame to allow a wood floor to slide under the jam.

- Sanding, scraping, polishing etc

- Rasping - a carbide rasp will quickly eat through rotten wood, tile glue residue, old putty etc.

Who will find a use for one?

Anyone doing general DIY, Handymen, Tilers, Glazers, Plumbers, Electricians.

The Tools

| Oscillating tool blades | |

|---|---|

|

b |