Overhead rail goods lift

This is a design for a Goods Lift that occupies no floor space, is quick to construct, and costs very little. It uses an overhead rail and no goods cage, with goods being carried on a rope. The rope is fitted with hooks, and on these may be hung the goods to be lifted, or a sling or heavy duty bag. The lift mechanism fits overhead in a standard domestic stairwell.

Materials cost of these starts at about £100 for a basic 100kg lift, and they may be made and fitted in an afternoon once everything is to hand.

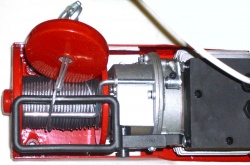

Hoist

The hoist is a standard 125kg electric hoist, and is fixed to the wall.

Hoist Fixing

Many hoists have M8 threaded sockets and can be fixed to the wall with M8 rod threaded throuh holes drilled in the wall. For exterior walls the rods could be resin fixed into the wall.

However such a basic setup makes for a noisy installation, and noise reduction is needed if its to be used more than just occasionally.

To decouple hoist from wall the following are mounted on the threaded rod in order: hoist, 3/4" tap washer, wall, 3/4" tap washer, penny washer, locknut. The hole in the wall is lined with soft flexible plastic tubing to decouple the threaded rod from the wall.

The 3/4" tap washers are drilled to produce a larger centre hole, enabling them to fit onto M8 rod. To do this the washer is held still by sandwiching it between a piece of wood underneath and a predrilled piece on top (with a larger hole). Its quicker to just stand on the wood pieces than to clamp it all up.

Endstop

Hoists may have automatic endstop devices that can interfere with their use in this position. Electric hoists are mostly designed for vertical lifting rather than lifting at an angle to the horizontal. There are 3 ways to resolve this:

- Modify the mounting of the autostop sensor ring so that the lifting wire passes through it without fouling.

- Mount the hoist at an angle to the wall, using a wood spacer behind the upper fixings, and wall holes drilled at the necessary angle for the threaded rods.

- Remove the autostop device and make a manual power switch available. For this to be safe there must be a physical stop device that prevents the lifting hook from being pulled round the lifting drum, plus a suitable fuse used which will rupture if the motor is persistently stalled.

Rail

The rail is mounted above head height parallel to the stairs. 2x4 PAR is good for 100kg loads, and is fixed at each end using coach screws. The rail must be free of cracks. Much longer than usual runs would require larger timber.

Smaller timber is unsuitable, as not enough wood remains above the coach screws.

3 screws are used at each end of the rail to give redundancy, as a safeguard against fixing failure. Large load spreading washers are used.

The rail should extend upward a foot beyond the edge of the upper floor, as the trolley can not reach the end of the rail, and the load may trail a little behind the trolley. The rail also extends a little beyond the bottom of the stairs because the rope can't travel to the rail end.

The rail is spaced away from the wall using a small piece of wood behind the rail at each fixing point. Matching spacers can be cut off the rail end, or smaller timber used.

The 4 long corners of the rail are routed round or planed to 45 degrees like so:

_______ / \ | | | | | | | | | | | | | | \_______/

In low strength walls, sufficient pullout strength may need to be tested. Resin fixing is the strongest option, if needed.

Its also possible to use a heavy duty sliding door mechanism as an alternative to the rail & trolley, but they don't look as nice and cost more. Light rail mechanisms for cupboard doors are unsuitable.

The rail is fitted to the wall parallel to the stairs.

For rails fitted at steeper than 45 degrees, load rating will be reduced non-proportionally. See Load Rating section for details.

The rail and the trolley are polished with silicone furniture polish to minimise friction.

Trolley

The trolley is a small sliding piece that rides on top of the rail. When the hoist is above the line of the rail, the hoist cable is attached to the top or the front edge of the trolley. When the hoist is below the line of the rail, the goods rope is looped under the trolley and the listing cable attached to it. The latter case requires a bottom to the trolley to prevent its sides being squeezed against the rail.

The trolley is a U or O shaped wood or metal collar. If metal it has its edges bent outward slightly to avoid catching on the wood. It may be possible to make one from a joist hanger.

The goods lifting rope loops over the trolley and is attached to it. The rope is attached at the bottom of the trolley's sides so that the weight being lifted prevents the trolley from tipping over. Rope may be attached to a wooden trolley by screwing through the rope with a couple of 3mm x 1" screws with washers. Rope is attached to a metal trolley using heavy duty cable ties, 2mm iron Wire, or crimp fittings.

For testing, a temporary wooden trolley can be used. This is simply a small block of wood riding on the top of the rail with the lifting rope attached to its top. This is not a permanent trolley as

- it has no sides, and the rope would gradually rub through & fail.

- it can fall off

Rope

Like everything else, the rope should be rated to well above 100kg. Since it can experience jerkiness under full load it should be rated to several times 100kg. Unrated rope can be tested. Sash cord has the advantage of a rounder profile, looking better in a domestic setting, and the few brands used have proven upto the job.

S hooks are tied to the bottom ends of the rope, and the load is hung on these. Butcher's hooks are not suitable, they're too sharp & thin.

Rope ends can be kept neat & prevented from fraying by holding the rope end in pliers with half an inch poking out, and applying a lighter to melt the end into a blob. The flame should not touch the rope, or burning occurs. This doesn't work with natural fibre ropes of course.

Maintenance

Any type of lift should be inspected periodically. There are no failsafe mechanisms, so a broken rope would result in dropped goods.

Check for visible damage, including worn rope, loose rope knots, damaged lift wire, or loose hoist fixings. The parts most liable to damage are the rope and lifting wire.

Safety

The fact that these are only used for goods avoids many safety issues, but the lack of backup support systems means that dropping of the load is possible if a fault occurs. Consequently the user should not walk under or below the load when in use, nor permit others to do so.

Although physically able to lift people, the design does not meet the safety and legal requirements for doing so. In situations where kids are liable to play with it, it should be fitted with some way to prevent use. Options include a key operated switch, or a removable control switch lead or power lead, preferably using an obscure connector, such as shown above.

Rope knot failure due to poor knot technique is possible, and knots should be checked and load tested before the machine is put into service.

The hoist's lifting wire should be attached to the goods rope as well as the trolley. This way, a trolley failure wouldn't cause dropped goods.

The risks involved with light goods lifts are tiny compared to passenger lifts, but in any DIY activity there is always scope to go wrong and end up causing injury. Falling or uncontrolled loads can cause injury, and only you are responsible for the results of your actions.

Readers should not rely on wiki articles for safety critical information. This is intended as an informational article describing a system in use, and no more. It does not constitute a recommendation of construction or use. You alone will live with the benefits and possible risks if you choose to implement or misimplement anything on a website.

Like any informational article, covering every possible issue and explaining it fully and clearly to every possible reader is a tall order, and can not be assumed. See Wiki Safety.

Weight Rating

A 125kg hoist with the above design gives a 100kg load rating.

For any given load rating, all load carrying elements must meet the rating, including hooks, rope, rail, hoist, and rail & hoist fixings. Some of these parts see higher forces than the load weight due to friction or forces acting in more than one direction, and these will need to handle above the system load rating. All items also need a large load safety margin. Note that this refers to survival rather than ability to lift, so the hoist need only be rated to 125kg lifting capacity in order to carry 100kg. (A 125kg hoist can survive load forces of several times its lifting ability.)

Hoists require a higher load lifting rating than the load to be lifted, since they have to overcome trolley friction as well as lift the goods. A 125kg hoist can lift 100kg with rail angles of 45° or less.

For rails fitted at steeper angles than 45° from the horizontal, load multiplication and increased friction occur, and the system load rating becomes significantly less than the load rating of each individual component. This design of lift is unsuitable for very steep stairs, such as alternating tread space savers.

Don't overlook the carrying capacity of the wall itself. Strawboard walls are inadequate for these systems. Timber stud walls must be reasonably well constructed to be strong enough, occasionally they're not. If in doubt the goods lift can be briefly tested with double the desired load rating, while keeping a safe distance - but be prepared to fix a large hole.

Noise

Many electric hoists are very noisy in use, but this is easily solved for domestic use with a little noiseproofing.

Ways to address this include:

- pick a quiet hoist

- Decouple hoist from wall & enclose hoist in a damped box.

Damped box

Since 1/2" sheet Materials are so common, a suitable box may be made from 1/2" sheet, preferably with a second layer of sheet glued on to give greater rigidity.

The box is then lined inside and out with damping materials. Carpet offcuts are a suitable readily available lining. 2 carpet layers internally gives excellant damping. Carpet is best glued in place.

The box interior is sized to give 2" clearance from the hoist all round. A slot in the front is needed for the steel lifting cable. This slot lines up with the centre of the hoist's cable drum. The slot is 2mm wider than the cable, and long enough to accommodate the cable at each end of its run (top & bottom of rail). Carpet covers this slot inside and out to maintain noise reduction: the carpet is slit but not cut away.

External finish is your call. An easy option is to line the box with carpet, which gives some extra sound filtering as well. This is easy to fit and completely hides the wood box, making it possible to use any Sheet Materials to hand without any attempt at neat cabinet making. When the box will be carpeted, the 2nd layer of sheet material attached to the box is made slightly smaller than the box all round. This gives rounded corners to the external carpet.

A continuous lip of thin wood is glued to the wall just inside where the wooden box sits, using no more nails or similar and about 5mm wide x 1/2" split wood strips. This is part of the noise reduction system, and blocks the direct sound path from inside to outside the box. These are fitted with a quarter inch gap between the strips and the box. This makes it easy to fit the box, and creates a noise reducing serpentine sound path from interior to exterior. To position the strips, the box is held in place and drawn round with pencil. The strips can then be attached the rihgt distance in from the pencil line.

The box can be fixed to the wall with 4 small corner braces. The carpeted exterior hides these.

Boxless hoist

Where absence of a visible box is required, the hoist box can often be mounted in the attic, the cable passing through a small slot in the ceiling. The slot must be steel lined, as cable fraying would quickly saw through plasterboard.

Supplies

- Toolstation hoist

- Screwfix hoist

- Goods hooks

- Rail: 2x4 redwood PSE, from any timber merchant.

- 16cm Coach screws