TT Earthing

Introduction

This article is about the building and testing of TT Earth systems for electrical installations. Note we are not discussing earthing systems designed to offer protection from the effects of lightening strikes.

What is a TT Earth and why would I want one?

If you refer to the Earthing Types article you will see there are a number of ways that an earth can be provided for an electrical installation (there are some nice graphical illustrations of the different types in this article). Of the available types TN-S and TN-C-S, where your electricity supplier also provide an earth, are by far the most common. The next most common category is the TT type. You will encounter this situation where the electricity supplier does not provide any connection to allow the installation to be earthed, or you are working on an electrical installation in an outbuilding where it was not appropriate to export the main earth (see Taking electricity outside for more info). In either of these cases you are responsible for providing your own earth connection.

Since a TT earthing system will safeguard both lives and equipment it is important that a correctly designed system is installed. It should have:

- Low enough electrical resistance to earth to ensure correct operation of the circuit earth fault protection device (typically a RCD).

- Good repeatability (i.e. it should be able to carry fault currents repeatedly, and its performance should remain in spec all year round, irrespective of varying soil conditions)

- High resistance to corrosion

- Long life expectancy

Types of earth electrode

The usual way to provide an earth is to place an electrode into the soil. There are a number of ways of doing this, and how well each of them will work will depend to a large extent on the local soil conditions.

Earth Rods or Spikes

Earth rods are commonly used since they are easy to retrofit to properties and also work well for a relatively small overall rod area. A typical earth rod is 1.2m long and something like 9 to 14mm in diameter, and usually made from copper clad steel, solid copper, or sometimes stainless steel. This is driven into the ground and an electrical connection made to the top of it via an earth clamp. If the resistance achieved with one rod is too high, then most rods have a threaded section that will allow an additional one to be connected to it, and then that too driven into the ground. (Note that the overall length of the electrode has far more effect on the resistance than the diameter).

The connection to the earth rod should be protected with a suitable enclosure, and this must feature a warning label stating that "this is a safety electrical connection and should not be removed."

Driving an earth rod

The usual solution to this is to hit it with a hammer, and keep doing so until it is nearly all gone. However a modern and much simpler equivalent is to use a SDS drill set to hammer only (i.e. rotation stop) mode, fitted with a square drive adaptor and a socket. The socket will keep the drill centred on the spike and should allow you to "power drive" it into the soil.

For many rod sizes you may also obtain a "driving head". This is a cover that will protect the top end of the rod from damage while driving, which will be important if you need to attach and drive further rods to the first one.

You should choose a section of ground that is away from other service pipes and drains, and preferably is comprised of ordinary soil rather than builders rubble. This will not only make driving the spike easier, but will get a lower resistance electrode as a result.

If the spike hits something immovable and will not drive any further you may be able to pull it out and try elsewhere, or if you managed to drive mostly home before it stopping then it may be worth testing as is and cutting off the excess if the result is good enough. If one rod position on its own is not good enough then additional rods can be driven in other locations and "paralleled up" to lower the overall resistance.

It is wise to try an keep a few meters away from other rods so as not to overlap their resistance area (how far, will depend on how good a conductor the local soil is. The poorer it is the closer they can be together).

Earth Plates

These are typically either solid copper plates, or lattice like plates made from copper rods. These need to be buried in suitable ground. They can not be "driven" later, and require excavation of soil to fit.

Alternative earth types

Alternative systems are sometimes used such as earth tapes or wires that are run through long channels dug in the ground. Again difficult to retrofit, and not suitable for soils that require deep penetration to reach permanently damp and frost free conditions. There is also an earthing system constructed using the foundation slab of some building types called an Ufer Earthing

Quality of earth

The quality of the earth obtained will depend to a large extent on the soil moisture content. Soils that stay damp all year round (like heavy clay) will often perform well in this context. You may need more than one rods length to reach the permanently damp soil.

Different soil types will affect the performance. Marshy ground will perform best, with loam, clay, peat and often chalk also working well when damp. Dry sand and rocky ground however can be much harder to get good results with.

Pay attention to temperature range as well. Frozen ground can be ten times less effective than warmer soil.

Soils with high mineral salt content in their moisture will usually perform noticeably better than "ordinary" damp soil.

Testing the electrode resistance

The aim of the exercise is to achieve a reasonably low resistance path to earth. Usually with this type of earth it is unrealistic to expect to achieve a resistance as low as that you would get from a supplier provided earth (i.e. under 1 ohm), however it is usually possible to achieve a resistance well under 100 ohms, which when combined with an RCD will offer adequate protection.

When testing the resistance of an earth electrode it is important that any parallel connections to earth (such as main equipotential bonds to water or gas mains) are disconnected when the reading is taken. Note that any occupants of the premises should be warned since they may be exposed to increased shock risk for the duration of the testing. Any disconnected equipotential bonds must be reinstated once testing is complete

With an electrode tester

There are a number of proprietary earth electrode testers available which automate the manual current and voltage sensing approach described later. Refer to the specific units documentation for instructions on use, since the procedure differs a little between devices.

With an earth loop tester

You can use an earth loop tester to directly read the resistance of an earth electrode (or at least read a result close to it). Here you connect your loop meter to a suitable socket, and push the "test" button. Note, you may have to bridge out the RCD protection for the socket (depending on the sophistication of the test meter). This will give you a reading of the whole earth fault loop impedance rather than just that of the earth electrode. However this will be a good approximation to the resistance of the electrode since it will usually be significantly greater than that of the extra wiring introduced by this test (you can always estimate or measure the resistance of the circuit wiring to subtract from the measured result to obtain a more accurate figure).

Without specialist test gear

Anyone with a bit of electrical common sense, knowledge of Ohm's law, and a decent multimeter can measure earth electrode resistance quite easily. You need to isolate the electrode in question and then find a way of getting some current to flow into it. A safe way to do this is to use a double-wound mains transformer with a secondary voltage of around 24V (exact value not critical). It is preferable to use AC for this test since that eliminates any electrolytic effects (if you must use DC source such as a car battery, then conduct two readings, reversing the polarity for the second).

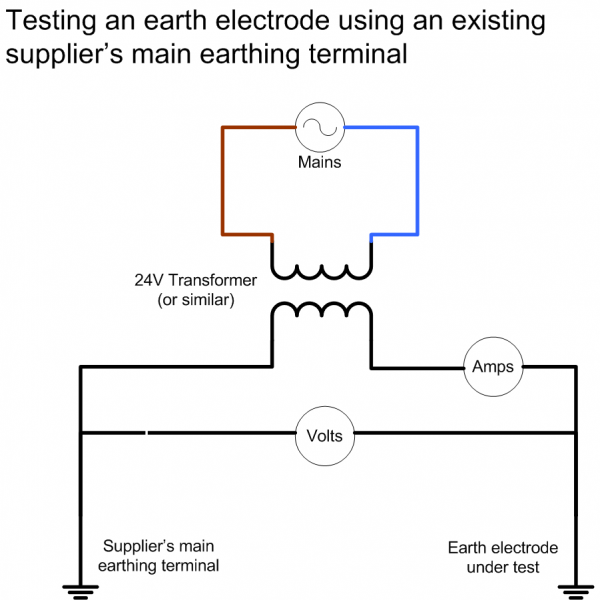

Using an existing supplier's earth

Exactly how you wire this up will depend on the circumstances. If you have a TN system installation where you are adding an earth electrode for an outbuilding etc, then you can make use of your existing supplier provided earthing point as a return path: Connect one end of the secondary via a suitable length of wire to the main earth terminal in the house and connect the other end to your earth electrode via an ammeter:

Energise the primary of the transformer, and the secondary current which flows will immediately give you a rough idea of the total resistance in the circuit, most of which will be attributable to the electrode under test.

For a more accurate result, drive a second temporary earth electrode (a 2ft offcut of 15mm water pipe will do) into the ground at a distance of at least 10m from the one you're measuring. Then use the meter on an AC volts range to measure the voltage drop between the two electrodes. Dividing this figure by the electrode current measured earlier, gives you the earth electrode resistance. Move the temporary reference electrode to a second position and repeat. Average the two values obtained, but if they are significantly different, try further positions for the reference electrode.

(as long as the temporary electrode is far enough away from the electrode under test, you can assume that your voltage measurement is a direct measurement of the potential difference between that of the general mass of the Earth, and the electrode under test. Since your voltmeter will not draw any significant current for the measurement, you can ignore the resistance of the temporary test electrode since the voltage drop due to this will be negligible)

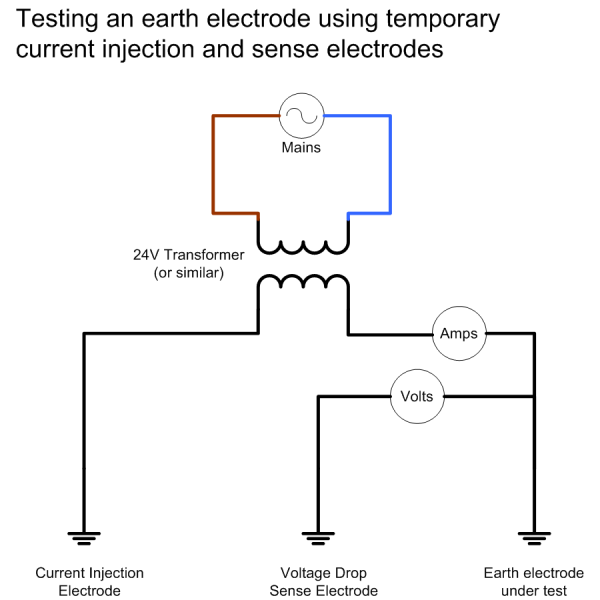

Using temporary current injection and voltage sense electrodes

If your whole installation is TT system to start with or you can't easily make contact to an existing reliable earth connection, then you will need to adopt an alternative approach. For this you will need two temporary electrodes. One positioned at least 20m from the one under test, and a second one in a straight line initially placed midway between them:

Upon energising the transformer, a current should flow between the first temporary electrode (shown as the Current Injection Electrode in the diagram above) and the electrode under test. However since we don't know the resistance of this temporary electrode, we will need to use a second temporary electrode (the Voltage Drop Sense electrode as shown above) to take the voltage reading. Put this one roughly half-way between the other two, and take a measurement. Repeat the test moving first a metre or so closer to the first temporary electrode, and then toward the electrode under test. The readings should be very similar. If there is more than 10% difference, then is likely that your electrodes are too closely spaced, and their resistance areas are overlapping too much, hence making it difficult to get a reading relative to the Earth's true potential. Once you have a reliable voltage reading, dividing this figure by the electrode current measured earlier, gives you the earth electrode resistance.

Connecting to your earth

Table 4.2 in the OSG provides the cable cross sectional areas required for a TT main earth connection. These are:

| Installation method | Minimum cross section (mm²) |

|---|---|

| Not buried, unprotected | 4 |

| Not buried, Protected against corrosion | 4 |

| Not buried, Protected against corrosion & Mechanical damage | 2.5 |

| Buried, unprotected | 25 |

| Buried, Protected against corrosion | 16 |

| Buried, Protected against corrosion & Mechanical damage | 2.5 |

Note these values apply when the earth electrode resistance is 1 ohm or greater. TT systems with electrode resistances of less than one ohm, should be treated as TN systems.

External Links

Furse, well known manufacturer of earthing products

IEE Wiring Matters article (see PDF page 13).