Difference between revisions of "Taking electricity outside"

(→CPC sizing: Brain fart in equation) |

(→SWA Cable: spurious [) |

||

| Line 157: | Line 157: | ||

| − | Although these figures have been presented for SWA cable here, the values quoted are in general correct for other cable constructions. It is worth nothing however that these figures assume that the cable is operating at or near its maximum operating temperature. In designs where the maximum current load is significantly less that the capacity of the cable then these figures will be somewhat pessimistic. For these circumstance, it would be more appropriate to calculate voltage drops based on table 9A of the | + | Although these figures have been presented for SWA cable here, the values quoted are in general correct for other cable constructions. It is worth nothing however that these figures assume that the cable is operating at or near its maximum operating temperature. In designs where the maximum current load is significantly less that the capacity of the cable then these figures will be somewhat pessimistic. For these circumstance, it would be more appropriate to calculate voltage drops based on table 9A of the [http://tinyurl.com/32yb6h On Site Guide]. |

Revision as of 20:30, 5 June 2007

| This page is awaiting peer review and comment.

Please do not rely on any information presented here yet. --John Rumm 22:49, 4 June 2007 (BST) |

Taking electricity outside

This article discusses various ways power can be delivered to outbuildings like sheds and garages on a permanent basis. While in concept this does not sound as if it should be any more difficult than extending a power circuit from one room to another room in your house, there are a number of quite subtle details and safety issues that come into play as soon as you venture outside.

Note also that most of the work described here would be classed as a "notifiable work" under Part P of the building regulations.

Decide what you want to do

This is probably the most important phase of the project, since if you don't think this bit through well enough you could end up spending lots of time and money on a solution that will not do what you need.

The primary questions to answer are:

- What do you plan to do with it?

- How much power is required?

What you plan to do in the outbuilding will dictate the power required. If all that is needed is a socket or two and some lighting, then the power requirements are fairly modest, a 13A supply would probably be more than adequate. To power a full workshop including equipment, lighting and heating however may require a far more substantial power supply. For the purposes of this article we are going to limit our focus to supplies that can reasonably be taken from a normal domestic household supply. If you need more power than that, then you may need to approach your electricity supplier about providing a dedicated supply to your outbuilding.

To estimate the total power requirement, think of the likely activities, and what equipment will be involved. What devices could you conceivable need to use at the same time. For example in a workshop you may need to use 1kW of dust extraction, a couple of kW of power tools, a kW of heating, and perhaps allow another 400W for lighting. If you add on some contingency for future expansion you get say: 5kW total, so perhaps a 20A or maybe even a 30A supply would be needed.

Design

Design is the process of working out how you are going to achieve each part of the installation, and what type of equipment, and of what required current rating, is going to be required for each part. We need to look at three aspects of the design:

- Head end: This is how you will take power from the house electrical system

- Submain: How you will wire the connection between the house and the outbuilding

- Outbuilding equipment: How you will select and install appropriate equipment for the outbuilding.

Each of these areas have to be addressed to ensure that the final result meets the required regulations and standards, does what you need, and is above all safe.

Note to complete this design exercise correctly you will need access to copies of BS7671 (the wiring regs) and the IEE [On Site Guide (OSG)

What you need to know

Distance

One of the primary things you need to know is how far do you need to take power. This is not only the straight line distance between the house and the outbuilding, but also the distance from the consumer unit to the start of the electrical system in the outbuilding "as the cable runs", which may be significantly further.

The primary problem that distance introduces is that of voltage drop. The longer the cable, the bigger its resistance, and the more voltage drop introduced for any given load.

Earthing

There are three commonly encountered earthing systems in use: TN-S, TN-C-S, and TT (see Earthing systems for more detail). It is important that you establish what type of earthing your property uses and this will influence the rest of your design.

Usage

The pattern of power usage you expect to make in the outbuilding will also influence your design. A design intended to provide power to a storage shed with one light, and a socket for running the mower and other garden tools from, probably does not need to worry about details like ensuring that the light does not fail should some other fault cause the power to "trip". Whereas in a workshop where you may be working at night with power tools or machinery this is a far more serious concern. A garage supply that will be used to run a chest freezer will need to make sure there is very little likelihood of a nuisance trip (see RCD) causing the contents to defrost.

Head end design

From an existing circuit

Generally this form of supply should only be used for the simplest and smallest power feeds (i.e. no more than a 16A supply), since general purpose power circuits designed to supply sockets in the house, are not intended to provide power for heavy fixed equipment, or to supply substantial currents as a single "point load". You must also take into account the existing loading on the circuit before deciding to place additional demands on it. For example, many kitchen ring circuits often have existing loads that approach their full capacity.

This type of supply may be ideally suited to the provision of a single waterproof socket mounted on the outside wall of the building.

You will also need to take note of if the chosen supply circuit already has RCD protection. If it does not, then this must be provided for any socket outlets (with a trip threshold of no more than 30mA to offer adequate direct contact shock protection).

If it already has RCD protection, then this may make it difficult to meet your usage requirements since it might then be difficult to provide a lighting system that is not vulnerable to interruption in the even of another fault.

From a spare way in the CU

This is the more practical solution for most installations. It will allow you to take more power and in a way that will not affect other existing circuits. If you have a TN-S or TN-C-S system then you would ideally want to take power from a non RCD protected way on your consumer unit, this is to guard against the outside power feed increasing the likelihood of nuisance trips being caused on the household RCD, and also to prevent the RCD from making discrimination difficult for the outbuilding supply.

If your CU does not have a spare RCD unprotected way (or has a "Whole house RCD"), then consider using the independent supply method described below.

Using an independent supply

Where there is no available spare (or appropriate) way in the consumer unit, one can add a separate feed to a new consumer unit or switchfuse (this needs to be nothing more elaborate than a small DIN rail enclosure large enough to hold a switch and suitable protective device(s)).

To feed this new CU, a big junction box called a "service connector block" (or "Henley block") is used to split the exiting tails from the meter. The service connector block typically has room for five separate pairs of tails, so one pair of connections is used as the input and two pairs take power to the old and new consumer units. Probably the most elegant way to use this it to take the existing tails from the meter into a master switch first, and insert the Henley block after this. That way you retain the ability to kill the power to the whole installation with a single main switch.

(This picture shows a Service Connector block being used to split the tails from the electricity meter. Note the original PBJ tails from the meter enter at the top of the switch, and new tails feed out to the connector block)

The size of the tails used needs to match or exceed that of those used for the existing supply. This will typically be 16mm² for a 60A supply, or 25mm² for a 100A supply. If in doubt use the larger size since this will allow for a future upgrade to the supply without needing to replace all the tails. The new CU should have its earth terminal connected to the exiting main earth terminal using 16mm² earth single (6mm² on TT installations).

Choosing protective devices

It is necessary to provide protection for the submain since this will be vulnerable to damage, either en-route to the outbuilding, or in the outbuilding itself (especially where the building is readily combustible)

Provision of fault and overcurrent protection

Appropriate protection needs to be provided to protect the submain cable against fault and overcurrent. The most appropriate devices for this being either a MCB or a HRC cartridge fuse (fuse carriers are available in a MCB shaped enclosure for many brands of consumer unit). The fuse often has a slight advantage in that it will usually offer better discrimination with a downstream MCB. When using a MCB one often has to size it at least two ratings higher than the highest rating downstream device to ensure discrimination. This can be impractical in many designs.

The rating of the protective device will need to be selected so as to adequately protect the cable used. Note however that further calculations are needed to prove this devices is adequate (see submain design section)

Earth fault protection

For TN-S and TN-C-S installs one can usually rely on the fuse or MCB to also protect against faults to earth (i.e. spade through cable, or shed gone up in a puff of smoke errors!). With a TT install, additional protection will be required in the form of a RCD to protect against faults to earth, and maintain adequate shock protection from indirect contact faults. With the simplest outbuilding setups, it may be appropriate to use a 30 mA trip threshold device at the head end of the cable and forgo any further RCD protection in the outbuilding. Whilst this is a cheap solution, it is non optimal in many cases since it prevents the discrimination in the event of a fault to preserve lighting in the outbuilding, and also means that one has to return to the head end to reset the RCD should it be tripped. A more practical solution is to use a 100 mA trip time delayed device.

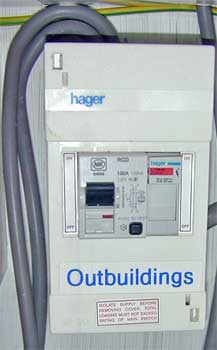

(This is a switchfuse on a TT head end, assembled from a small DIN enclosure. The incomer device is a 100mA trip RCD with time delay, and overcurrent protection is provided by a 30A HRC fuse in a fuse holder)

Sub main design

This section deals with choosing an appropriate cable type, and checking the design parameters to make sure it is adequately protected.

Cable choice

The most commonly used cable types are flat T&E, HiTuff, or Steel Wire Armoured (SWA) cable. For more details including current ratings for the different cable types please see the main Cables article.

Cable types

| Cable type | Useage |

|---|---|

| Flat T&E | Twin and Earth cable is not suitable for use outside unless protected inside conduit or trunking, since the insulation is neither robust enough for direct burial, and the PVC is attacked by the UV in sunlight which causes it to harden and crack.

T&E would usually only be used outside for short runs in protective conduit, often clipped to the outside of the main building. Typical applications being connections to outside lights. T&E is however often used for the first part of a submain that makes the journey from the house CU to the point of exit from the building. One weakness of T&E that needs to be considered, is that its CPC is usually smaller in cross section than its main conductors. This will have a negative impact on the overall earth fault loop impedance of the submain. |

| HiTuff | HiTuff is multicore flexible cable. While it is not suitable for direct burial it is robust enough for most other applications such as being clipped direct or suspended from a support wire. It will remain flexible under a wide temperature range, resists abrasion, and it is not affected by UV exposure. |

| SWA | SWA is usually the cable of choice for many installations since it is available in a good range of core sizes, it is very robust, and can be buried directly into the ground with no need for further protection. Note that SWA is available with two alternative types of outer insulating material: PVC, and XLPE. The XLPE variety has a higher maximum operational temperature (90° C) compared to PVC (70° C), and hence a higher maximum current carrying capacity.

SWA is frequently not brought right into the building at the head end since it is relatively inflexible and difficult to work with. |

Voltage drop

Your design must ensure the maximum voltage drop allowed between source and point of use is not exceeded when at full load. This is usually defined as 4% of the nominal supply voltage (about 9.2V at 230V AC).

You also need to allow some of this voltage drop "budget" for the final circuits in the outbuilding.

SWA Cable

| Conductor CSA (mm²) | PVC (max 70° C)

Voltage drop mV/A/m |

XLPE (max 90° C)

Voltage drop mV/A/m |

|---|---|---|

| 1.5 | 29 | 31 |

| 2.5 | 18 | 19 |

| 4.0 | 11 | 12 |

| 6 | 7.3 | 7.9 |

| 10 | 4.4 | 4.7 |

| 16 | 2.8 | 2.9 |

Although these figures have been presented for SWA cable here, the values quoted are in general correct for other cable constructions. It is worth nothing however that these figures assume that the cable is operating at or near its maximum operating temperature. In designs where the maximum current load is significantly less that the capacity of the cable then these figures will be somewhat pessimistic. For these circumstance, it would be more appropriate to calculate voltage drops based on table 9A of the On Site Guide.

Calculation Examples (PVC SWA): 1) 20m of 4mm², maximum load of 30A would drop 20 x 0.011 x 30 = 6.6V 2) 40m of 6mm², maximum load of 45A would drop 40 x 0.0073 x 45 = 13.14V 3) 10m of 1.5mm², maximum load of 16A would drop 10 x 0.029 x 16 = 4.64V (1) and (3) are adequately specified with respect to voltage drop. However (2) is out of spec and a larger cable will need to be selected, even though the current handling capacity of the 6mm² cable has not been exceeded. Upgrading to 10mm², gives a result of 40 x 0.0044 x 45 = 7.92V which is acceptable. It initially appears that this still only leaves just over 1V of remaining drop available for the outbuilding wiring, however since we will not be operating the larger cable anywhere near its maximum temperature, the situation is actually less tight than the calculation suggests.

Disconnection time

In the event of a short circuit fault in the sub main, the circuit protective device is required to disconnect the supply within 5 seconds. Two short circuit faults are possible: phase to neutral, and phase to earth. In the case of a TN-S or TN-C-S installation at the head end, we calculate the disconnect time for a phase to earth fault since this usually represents the worst case and the phase to neutral disconnect time will usually be the same or faster. For TT installations the phase earth disconnect time is dependant on the RCD, and hence can be ignored.

TN-S & TN-C-S Earthing at the head end

To establish the disconnect time we first need to calculate the earth fault loop impedance. This will comprise the sum of the impedance of the suppliers earth (Ze), plus the round trip impedance of the selected cable from the head to the location of the fault. Where a submain has more than one cable type (i.e. a T&E feed through the house, with a SWA section outside) the total impedance for each section should be added. In the absence of a measured value of the suppliers earth impedance one should take this as 0.8 ohms for TN-S and 0.35 ohms for TN-C-S systems (note that these values are pessimistically high, and may cause difficulties when designing sub mains for higher current supplies. In these circumstances is it advisable to actually measure the value and use the measured value in place of these worst case figures).

Example: A submain with 5m of 6mm² T&E and then 15M of 6mm² SWA on a TN-S supply protected by a 40A type B MCB. We will assume that the fault is at the far end of the SWA section, since this will represent worst case. From our Wire Resistance Table, we know the 5m of 6mm² cable will represent 10.49 mOhm/m or 0.052 ohms in total. From table 9A of the OSG, we know the 15m of SWA will give 6.16 mOhm/m or 0.092 ohms So total earth fault loop impedance Z(s) = 0.8 + 0.052 + 0.092 = 0.994 This gives a maximum prospective fault current of 230 / 0.994 = 231 A Reference to figure 3.4 in BS7671, shows the 0.1 to 5 second disconnect time for a 40A type B MCB will be achieved with a fault current of 200A (i.e. less than 231A) Therefore we can conclude that the design meets the disconnect time requirements.

If the required disconnect time is not met then the cable CSA will need to be increased or the protective device rating reduced.

CPC sizing

The final stage is to check that the CPC of the submain will withstand the duration of a fault condition for long enough to allow the protective device to operate. We know the section of T&E cable will have the poorest performance in this case, so we can check to see if its 2.5mm CPC is ok.

Continuing with the above example: s = sqrt( I² x t ) / k Where k is 115 for PVC insulated cable (table 54C of BS7671) s = sqrt( 231² x 0.1 ) / 115 = 0.64mm² Which is smaller that the 2.5mm² of the 6mm² T&E cable so we can conclude the cable's CPC is of adequate size.

Outbuilding equipment design

The final design stage to to select appropriate equipment for location in the outbuilding.

Know your environment

To make a sensible selection we need knowledge of the local environment. The phrase "outbuilding" can encompass anything from a damp draughty shed, to something as civilised as your front room.

Hence establish:

- How damp is the interior likely to get?

- Is it easy to make a good contact with earth? (i.e. A concrete floor in a garage that has no extraneous metal parts in contact with earth and no other services like water pipes entering the building will offer a good isolation from earth, whereas a greenhouse sat on damp ground would offer none.

Exporting an earth

The first major design decision to make is how the earth will be provided to the building. The options are to either export the house earth, or to use a local earth spike and create a local TT installation at the outbuilding.

| Earth Type | Limitations | Advantages | Disadvatages |

|---|---|---|---|

| Exported |

|

|

|

| Local |

|

|

|

When exporting an earth, the earth continuity must be maintained all the way through the installation from head end to submain, and into the final outbuilding circuits. With a locally (TT) earthed outbuilding this is not the case. Here the earth at the house end will typically be connected to the submain for the purposes of giving it fault and overcurrent protection for the run to the outbuilding, however it would be isolated at the destination. Here the local earth rod connection would be used for the outbuilding. One way to achieve this isolation when terminating at a CU is to use an insulated CU (i.e. plastic), and not fitting or connecting an earthing ring to the cable gland.

When something goes wrong

You need to consider how you are going to contain the impact of a protective device opening and cutting off power to a circuit, or the entire outbuilding.

With the simplest installations, RCD protection could be provided at the head end. This keeps the outbuilding install simple, but means in the event of a RCD trip all power is lost to the building. For a simple storage shed this may be acceptable.

With a workshop, more careful design is required to ensure that nothing short of physical damage to the submain will result in power being disconnected at the head end. Use of a split load CU, or emergency lighting could then ensure lighting remains on in the event of a power circuit trip.

When protecting power feeds to freezers or boilers in outbuildings, it may be appropriate to feed them from a dedicated circuit and treat them as fixed equipment. Thus the can be placed on the non RCD (or higher trip threshold) side of the outbuilding CU.

IT Equipment would be best protected with an uninterruptible power supply unit, and possibly a trip alarm.

Installation

Installing the head end

From an existing circuit

Turn off power to the circuit. An appropriate fused connection unit can then be inserted into the circuit to take power. In the case of non RCD protected circuits a RCD protected spur could be used (ideal for feeding external lighting circuits mounted on the outside of the house wall). For supplies to sockets on the outside wall of the house, it may be more appropriate to use a RCD protected socket. That way you would not have to come inside to in your muddy boots to reset the trip should it activate!

The cable from the spur can exit at a convenient point including from directly behind the FCU if a hole is drilled in a suitable place. Remember to drill any hole at a slight downward angle to prevent moisture ingress. Also construct a "drip loop" (i.e. ensuring the cable runs down first for a short distance at the exit point so that water can not run along the cable and be directed into the hole).

From a spare way in the CU

Turn off power at the CU. Remove a blanking plate and fit the protective device to the selected spare way. Remember when fitting a cable to a split load CU to connect the neutral conductor to the appropriate neutral bus bar.

Using an independent supply

Disconnect power to the CU. If you have a main switch available that can interrupt power to the CU then use this. Typically however this will not be fitted. In these circumstances it will be necessary to remove the suppliers main fuse that feeds the electricity meter. If the fuse has not been pulled previously then it will probably be sealed with a paper tape and/or wire seal. These will need to be broken or cut first.

It is vital that all loads are switched off before removing this fuse.

(The main fuse is shown on the right here, on this one the seals have already been removed)

Note that the main fuse is the property of the electricity supplier, and it is technically illegal for you to touch it. The "correct" way to arrange for disconnection of a supply is to contact your power distributor and book a visit from one of their contractors.

Most electricians will routinely pull main fuses without permission, and most suppliers will turn a blind eye to the practice (many would probably admit informally that they would rather the main fuse was pulled than someone attempted to work live).

With some designs of main fuse it can be advisable to cover the live end of the enclosure with insulating tape as a temporary safety precaution, since otherwise a live contact (now without fault current protection!) is relatively easily accessible to a misplaced finger or tool.

The existing meter tails can now be disconnected from the consumer unit and connected to the service connector block (preferably via a new "main switch" enclosure). Try to avoid breaking the seals on the meter end of the tails, by working only with the CU end. New tails can now be wired from the service connection block to the original CU and to the new CU. Remember to also use an appropriately sized earth single to connect the earth terminal in the new CU to the main earth terminal. Make sure that all terminals are well screwed down. Visually inspect your work, and then confirm all connections paths are as expected using a low ohms range on a multimeter. Refit the covers. Refit the main fuse (again ensuring there is no load present on any circuit).

Installing the sub main

In many cases the sub main will exit the building at the head end and vanish into the outbuilding at the destination. However with some of the heavier less flexible cables such as SWA this is not always easy. Here is is often easier to terminate the SWA at the outside wall of a building at a waterproof adaptable box using the correct waterproof gland kits, and join to a alternative cable such as T&E that will run the remainder of the distance inside the building. In some cases one may choose to just run the inner part of a SWA cable through the building to the head end (i.e. stripping the outer insulation and the armour) however an earth connection will need to be made to the armour when you do this.

Cable routing

Cables can be routed in anyway you like, so long as they are adequately protected, and supported along the route. Note that permanent cabling should not be run on a temporary structure such as a wooden fence.

Overhead

Cables can only be run a short distance in open space when unsupported. In most cases it will be necessary to erect a catenary wire first to support the cable. The cable is then tied to the wire at regular intervals to support it. This will prevent the cable stretching and the insulation being damaged or abraded at the point of support. The wire height shall be chosen to ensure that it does not pose any hazard to passing pedestrians or vehicles.

A cable supported like this must also be UV resistant, and of a flexible construction such as Hituf (T&E cable is not suitable)

Direct burial

Cables such as SWA are suitable for direct burial. There are no hard rules as to how deep a cable should be buried, but the depth should be appropriate for the situation. Under a path this may be as little as 400mm, but could rise to 700mm or more under part of a garden that may be "dug over". The cable trench should be cleared of any sharp stones that may damage the cable insulation. If this is not easy to achieve, then a lining of sharp sand or pea shingle can be laid in the trench first. After backfilling the trench the first 150mm, a PVC "Cable Below" tape should be laid before the rest of the trench is backfilled. That way anyone digging too close to the cable will hit the warning tape before hitting the cable.

Ducted

In some circumstances ducting may have been provided to take cables to the outbuilding. Note that it is not permissible to run power cables in the same duct as low voltage data and signal cables, unless it is a specially designed segregated duct designed for the purpose. Also note that ducting will probably require the derating of of the submain cables maximum current carrying capacity.

To feed a cable through a duct it is generally preferable to pull it through using a draw wire, rope or string (fishing line works well for this since it is slippery and string). To ease the process having an assistent push the cable from the other end can help. In extreme cases lubricating the cable can also help (there are dedicated cable lubricants available for this purpose, that will not damage the cable insulation).

Pulling the cable through may be easy, but that does leave the question of how to get the draw wire through in the first place! There are a number of options:

- The wire can be placed into the duct as it is assembled and buried

- For smaller ducts, a small section of rag tied to the end of the draw wire will enable it to be sucked through using a vacuum cleaner at the far end.

- Blowing it through with a supply of compressed air can also work - although you need to make a loose seal at the end you are blowing so as to keep most of the air in while letting the draw wire move freely.

- Using a set of push rods (or even drain rods on big ducts)

Installing the outbuilding equipment

A fundamental requirement for all electrical equipment selected for installation in your outbuilding is that it must be appropriate for the location and the expected use. This does not mean it has to be colour co-ordinated, but it does need to be moisture resistant if the building can not be assured of remaining completely dry. Some thought should also be given to impact resistance. In a workshop, that is to use surface mounted sockets, one of the "metal clad" range of sockets and accessories might be suitable since it offers better impact resistance. Adequate protection should be given to light fittings as well. Experience in my own workshop would suggest that the plastic diffusers on the fluorescent strip lights have save countless tubes from impact with over long planks etc.

Basic installs

The simplest systems to install are ones where there is just a feed to a small number of sockets and perhaps a light fitting. The overcurrent, fault, and RCD protection will have probably been taken care of at the head end of the supply. If the supply is not RCD protected then sockets with integral RCD protection could be used, or a RCD spur be installed to supply a small group of sockets.

Typically the incoming cable can be terminated in an adaptable box, and the wiring can continue directly to the sockets via flat T&E (radial circuit). In damp environments careful attention should be paid to fitting cable glands, grommets, and seals where needed (this also keeps out a good number of the small bugs that might otherwise seek to find a nice dry place to sleep!)

If the current carrying capacity of the interior wiring is equal to or greater than that of the overcurrent and fault protection provided at the feed cable head end, there will be no need for further protection at the transition.

To provide a supply to a lighting circuit a simple FCU protected with a 5A fuse can be used (or a switched fused FCU if you want to save the cost of a dedicated light switch!). It is better not to rely on switches integrated into the light fittings in most cases, since they may not respond well when groped with wet hands in the dark.

Mid range

Mid range installations will usually use a small "garage" CU. Small CU installs like this are useful for when it is necessary to provide local protection to various circuits rather than rely on blanket protection provided by the submain head end.

While these are a neat and simple solution, a failing of most of them is that they have a RCD which protects all circuits. While this will be a requirement for local TT installs (although a single 30mA trip RCD may not be the optimal solution), it may lead to unacceptable loss of lighting or other critical circuits. In these cases it may be necessary to look at full CU installs (see below), or to provide emergency lighting. Note for this reason this type of CU is not well suited to supply Freezer or boiler feeds in a garage.

The incoming submain cable can often be terminated directly into the CU. Alternatively an adaptable box can be used to change cable types to flat T&E if this makes the cable handling and routing (remember to allow for this in your design calculations).

Full consumer unit installations

In this catagory we will include any of a number of "roll your own" solutions that assemble CUs and protective devices from a range of parts, rather than using a packaged solution in a box.

A neat and simple solution for many installs of this type is the use of a simple non split load CU with a RCBO for the socket circuit. For TT installs the incomer switch can be replaced with a 100mA time delayed RCD, or alternatively a completely separate CU could be provided for non socket circuits with its incomer replaced by a conventional 100mA trip RCD.

For larger outbuilding installs with more than a couple of circuits, a domestic style split load unit may be more cost effective. This is an extension of the above.

Testing

Provision of a supply to an outbuilding should be tested as any new circuit should be. Special attention should be paid to insulation resistance checks, and also in the case of system with exported PME earths (TN-C-S head ends), the integrity of the local equipotential zone should be tested.

External Links

- Electrical Installations Outdoors article in IET "Wiring Matters"