Central Heating Controls and Zoning

This article is about Central heating systems using hot water as a heat-carrying medium. It is part of a set of articles about:

which you may wish to read first.

There are also articles about:

- Central heating operation for help maintaining a working CH system

- Central Heating Repair for diagnosing and fixing a faulty system.

- Motorised Valves

Zones

A zone is an area whose heating is under control of one time and one temperature controller, i.e. one timer and one thermostat, or one programmable thermostat. For example heating in a large house may be divided into one zone comprising living rooms and another zone comprising bedrooms, with a timer and room thermostat (or programmable thermostat) for each zone.

Underfloor heating is usually run as a separate zone from radiators.

Where Domestic Hot Water is heated by the boiler the water heating may be considered as a zone.

Always-on/Bathroom radiators

In some older systems it was common for the bathroom radiator to be connected across the flow and return pipework to the hot water cylinder, keeping the bathroom warm and towels hung over the radiator dried and warmed at all times. Where DHW is heated by gravity circulation the pipework to this radiator had to be arranged to allow gravity circulation through the radiator: typically the radiator would have a flow connection at the top and return at the bottom.

In some fully-pumped systems one radiator (often in the bathroom) was arranged to be open at all times (with lockshield valves on both connections) so as always to provide a path for hot water even if all other radiators are closed. In S-plan systems or where the boiler manufacturer specifies a bypass loop such an always-on radiator may be connected directly across the boiler flow and return, before the zone valve(s).

As a matter of design choice a bathroom towel radiator can be connected directly across boiler flow and return, before zone valves, to allow towels to be dried and warmed when either space heating or DHW re-heating is in operation. As long as the radiator is not acting as a mandatory bypass for the boiler it can be fitted with a TRV so that it does not waste heat in hot weather.

Zone control configurations

One zone

The simplest arrangement for a small house or flat with a combi boiler is to have all the radiators heated at the same time under control of TRVs and (usually) a room thermostat linked to the boiler (if the boiler has a time control built-in) or a programmable thermostat (which provides time and temperature control in one unit).

CH and DHW zones: Y-plan

Where Domestic Hot Water is provided from a cylinder (or similar) it is necessary to control the flow of primary water heated from the boiler so that the cylinder can be heated without the radiators (and vice versa). The usual arrangement in this case uses a 3-port "mid-position" Motorised Valve to direct the pumped flow from the boiler to either the central heating circuit or the hot water cylinder, or both simultaneously. This is known as a Y-plan system.

Schematic

Wiring

Internal workings of the valve

CH and DHW zones: S-plan

An alternative to the arrangement described in Y plan above, uses two 2 port zone valves in place of a single three port valve. This achieves a similar level of control as a Y plan system, but allows for further expansion into multiple heating zones at a later date (say to include discretely controlled under floor heating). One complication of a S-Plan system is that the boiler will need a separate bypass to allow water to pass through the system when all the valves are closed.

Schematic

Wiring

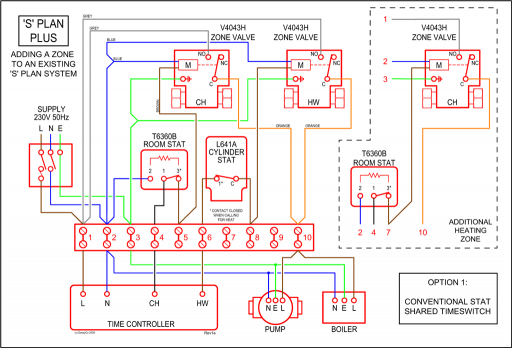

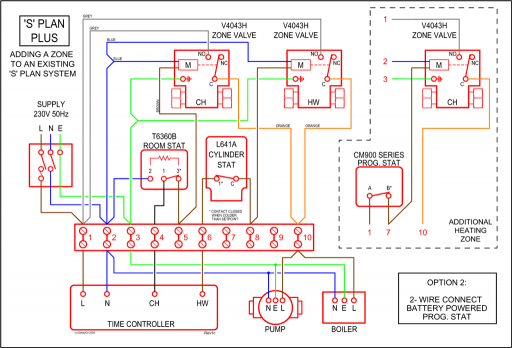

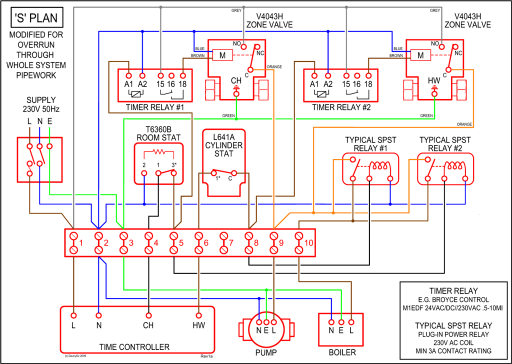

Multiple heating zones: S Plus-plan

This is an extension of the S-Plan arrangement described above. For houses with floor areas above a certain size building regulations require that the space heating is divided into multiple zones. In a conventional house layout the upper floor (bedrooms etc) is connected as one zone and ground floor as another. Each zone is controlled by its own thermostat (as well as TRVs where appropriate). Since larger houses will usually have stored hot water systems this will also require independent control. Where some parts of a CH system use Underfloor Heating and others use radiators the UFH is usually run as a separate zone. It may also be appropriate to treat kickspace heaters as separate zones.

In these cases 3 (or more) 2-port Motorised Valves are used connected in an S-plan configuration.

Schematic

Wiring

Note that the wiring for this plan is effectively the same as for S-Plan, but with additional thermostat and zone valve for each additional zone.

Bypass Valves

When demand from all the zones in an S-plan system has ceased and the zone valves have closed the boiler may still need to run on for a while to dissipate heat in its heat exchanger. In this case it is necessary to fit a bypass valve directly between the flow and return, before the zone valves. In older installations a gate valve was usually used, sometimes a type which could only be operated by a square-head key rather than having a wheel-head. This was adjusted to try to allow sufficient flow to let the boiler dissipate heat when the zone valves were closed, without diverting too much flow away from the heating circuits when the valves were open. In modern installations an automatic bypass valve is mandated. These let water flow from flow to return when the pressure generated by the pump is high due to the zone valves being closed, but don't pass a flow when any of the zone valves are open.

Note many modern system boilers now include automatic bypass valves built in as standard.

Gravity DHW: C-Plan

Older systems may be found to have gravity circulation to the DHW cylinder controlled by a 2-port (usually 28mm) zone valve in a C-plan system.

Schematic

Wiring

DHW priority: W-Plan

A variation on Y-Plan uses a 3-port Diverter (rather than Mid-Position) valve which switches all flow to either DHW or CH, never to both simultaneously. This is suitable for use with fast recovery DHW systems and is known as W-plan

Schematic

Wiring

Pump Plan

An alternative to using motorised valves to control the flow from a single pump is to use multiple pumps, one driving each zone. A packaged 2-zone Pump Plan system is available from Grundfos [1]. Pump Plan systems can also be constructed from individual components for two or more zones.

Adding Zones

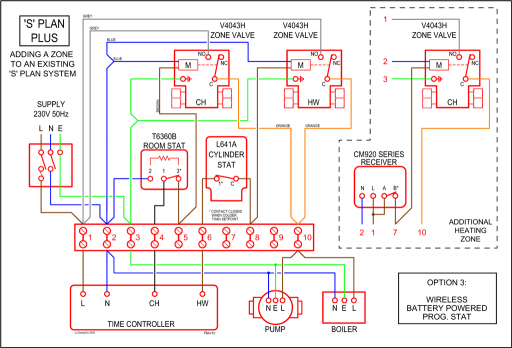

The following illustrations show how the control wiring for the above classic systems can be altered to allow additional zones to be incorporated into an existing system.

Adding a zone to a S Plan system

S Plan systems are relatively easy to extend. The first option uses the existing programmer / time switch, but adds an additional conventional thermostat for the new zone:

The second version shows a similar system but by using a programmable thermostat to give independent control of temperature and time in the new zone:

The next one, shows a variation using a wireless battery powered room stat:

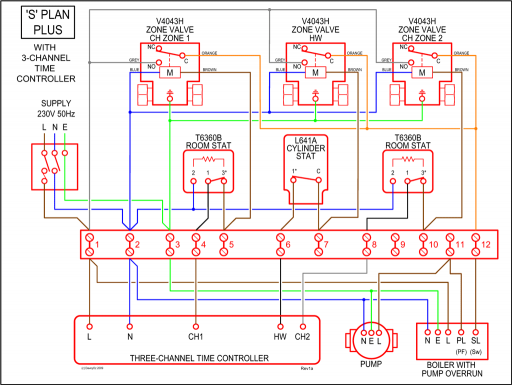

It is also possible to get multi channel programmers / timers that will allow direct control of more than one heating zone. This version also shows how the control wiring is modified to suit boiles that integrate their own pump overrun facility (see below for more detail on pump overrun):

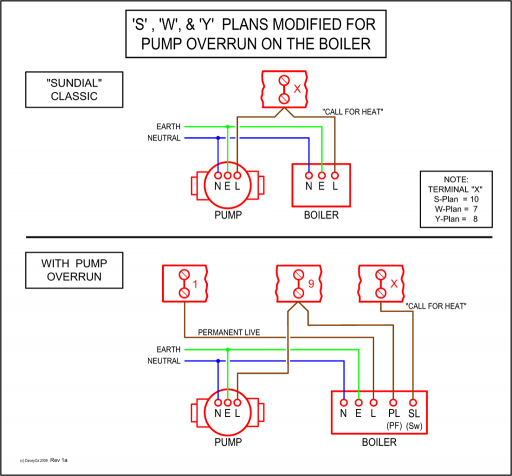

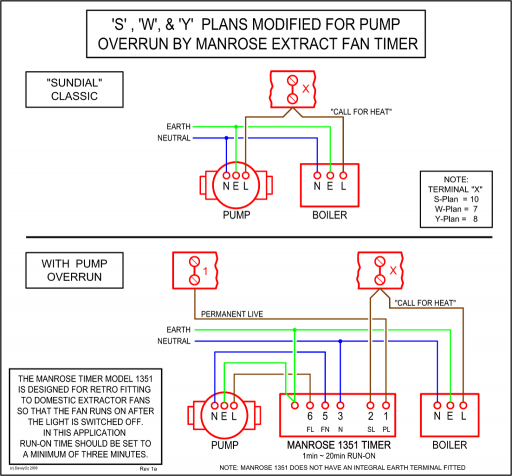

Adding Pump Overrun

The "classic" Sundial systems illustrated above are widely used and offer good functionality. However a weakness shared by each of them is the lack of provision for "pump overrun". Pump overrun allows the pump to continue to circulate water round the system after the room thermostat temperature demand has been satisfied and the boiler switched off. This improves the fuel efficiency of the heating system by allowing the hot water in the boiler, plus the residual heat in its heat exchanger to be extracted into the house, rather than simply allowing it to drift out of the flue. It can also reduce scaling and kettling in the boilers heat exchanger.

The simplest modification is for a boiler that has built in support for pump overrun. Note that on S Plan type systems you will normally require a automatic bypass valve to allow water to continue to circulate after the main zone valves have closed.

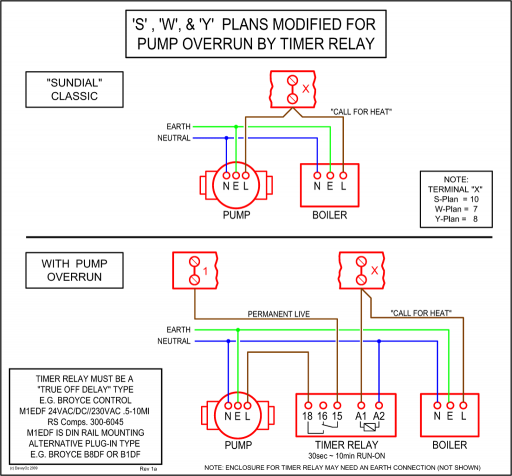

A similar arrangement can be used for boilers without an internal overrun timer by adding an external timer relay:

A variation on this makes use of a commonly avilable timer module designed to provide overrun on extractor fan systems:

One of the disadvantages of the simpler overrun systems is that once the stat has ceased calling for heat, not only is the boiler turned off, but also the zone valves may be closed. This then forces the overrun to flow through a system bypass (sometimes built into the boiler). This is good for the boiler and system, but its not as fuel efficient as allowing the spare heat to be used in the radiators. To achieve this is however a bit more complex since the timer needs to also keep the zone valves open to allow the water to flow through the rads, but at the same time inhibit the boiler from being triggered to fire at the same time. One solution is to use a pair of timers and relays like this:

Timers, programmers, thermostats, programmable thermostats

Programmers and Timers

The term "programmer" is often used for CH timers. There is no real difference between something described as a time switch or a programmer for a heating system. The purpose of the device is to pre-set at what times of the day you want the heating system to be operational.

The simplest programmers are mechanical devices with push in tabs on the periphery of a time wheel. This rotates once per day, and the position of the tabs dictates whether the heating is enabled or not. More modern devices are typically electronic, and usually allow the heating to be on, off, on once per day, and twice per day (where the time limits for the on/off periods can be set).

The programmer will also allow one to choose when the water cylinder (if fitted) is reheated.

Thermostats

A thermostat is a simple device that will typically turn the heating on when the temperature falls below the temperature it is set to. Then off again once that temperature is reached. They typically have no control over the actual rate at which the boiler can heat the house - all they can control is for how long the heating is run - the longer it runs, the warmer the house gets. Turning a stat "up" to warmer than the desired temperature, will not warm up the place any faster!

Older systems may not include a room stat - these instead rely on the presence of a stat built into the boiler. This cycles the boiler burner on and off to prevent the maximum water temperature from being exceeded. While this will allow the boilers water temperature control to be used as a crude house temperature control, it is not very effective since it does not react to the conditions in the same way as a room stat. Hence you will need to make frequent adjustments to it depending on how cold the weather is. Its also not very fuel efficient since it has no way of actually turning the heating off once the house is warm enough and the boiler is left cycling, wasting fuel, and possibly over heating the house.

Programmable stats include some of the capabilities of a timer as well as a stat. These usually allow the demanded temperature to be automatically changed at different times of the day, to suit the patterns of use of the occupants. The simplest ones have two temperatures - a heating one, and a setback one. More sophisticated ones may allow multiple different temperatures. Typical use may be to ensure the house is warm when people are getting up, then allow it to cool a little during the day, and raising the temperature during the evening before letting it fall to a "mostly off unless really cold" setting for overnight.

Additional Thermostats

Some houses have areas with quite different heat loss profiles. One example would be a partly underground building, where the upper storeys are exposed to exterior air temperature, but the underground floors are exposed to near constant soil temp all year round. Conventional heating control setups can not deal effectively with wide variations in relative heat output between areas. TRVs improve the situation, but they can not balance a system effectively, as too large an air temp variation is needed to achieve the large degree of flow modulation these situations require.

For such applications, 2 or more thermostats are required, one controlling the heat in each zone. Generally one timer will control both areas.

Thermostatic Radiator Valves (TRVs)

A Thermostatic Radiator Valve varies the flow of heating water through a radiator according to the temperature of a sensing element in the head of the valve (usually: a few models are available with remote sensing elements). This allows some automation of the control of the room temperature. Although the control is far from perfect, TRVs are a great improvement over manual valves for maintaining comfortable room temperatures in an energy-efficient way.

Bidirectional TRVs

A result of the design of TRVs is that they are liable to cause water hammer if fitted the "wrong" way round with respect to the flow of water through them. Most modern TRVs are designed to minimise the probability of this occurring and are described as bi-directional. One model (Danfoss' RAS-C revolver) has a design which allows the flow through the valve to be easily switched to the correct direction.

Where to fit TRVs

TRVs may be fitted to all radiators except at least one in the area sensed by the zone thermostat. Where only a few TRVs can be fitted (for whatever reasons) the greatest benefit is likely to be gained by fitting them to bedrooms (with the largest, hardest to heat first) followed by large halls and stairways, and WCs. All these can ideally be run at lower temperatures than main living areas so using TRVs to maintain lower temperatures saves more energy.

In a standard system if TRVs are fitted to all radiators and there is no room thermostat then energy will be wasted by the boiler cycling when all rooms are up to temperature. (There are, however, unusual systems employing thermal stores or other measures in which an all-TRV setup is intentional and energy-efficient.) The same problem can occur if TRVs are fitted to all radiators in a system that does have a room thermostat: if the TRV in the area with the thermostat closes down while the thermostat is still calling for heat it will continue to keep the boiler firing even when all the TRVs are closed.

TRVs and balancing

Fitting TRVs to radiators is not a substitute for properly balancing a system. They can mask, and to some extent ameliorate, the effects of poor balance.

Mixed Radiator and Underfloor layouts

UFH needs to be run at temperatures (circa 30°C) well below those used in radiators (c. 80°C). The standard way of reducing the temperature of water in mostly radiator systems uses a thermostatic mixing valve and a separate pump to circulate the UFH loop. Various cheaper schemes exist using e.g. a thermostat which blocks flow from the main CH pipework to the UFH when the UFH is up to temperature. Where a thermal store or heat bank is used to supply space heating it is often arranged with a take-off loop towards the bottom of the store supplying water at lower temperatures suitable for the UFH.

Special controls

Generally available controls are On/Off: they control the boiler with Demand or No-Demand signals.

Proportional controls (with analogue sensors) are available with some high-end boilers. They tell the boiler what the current temperature is so the boiler can determine how much heat to produce to acheive the desired temperature.

Weather compensation controls are also available with some boilers: an outdoor temperature sensor provides advance warning to the boiler of the likely heat demand of the building.

See Also

In this Wiki

External Links

- Downloadable PDF document containing all pipework diagrams from this page

- Downloadable PDF document containing all the wiring diagrams from this page

- Discussion of zoning on uk.d-i-y