Difference between revisions of "DIY Heat Bank"

Jump to navigation

Jump to search

(update image, add Components section) |

(add PHE data) |

||

| Line 13: | Line 13: | ||

* Thermostatic Mixing Valve (TMV) | * Thermostatic Mixing Valve (TMV) | ||

* Flow switch | * Flow switch | ||

| + | |||

| + | === PHE === | ||

| + | From: | ||

| + | GEA-Ecoflex | ||

| + | Unit 8, Waterside Business Park | ||

| + | Redwall Close | ||

| + | Dinnington-Sheffield | ||

| + | S25 3QA | ||

| + | Tel.: +44-(0)1909 551 107 | ||

| + | Fax: +44-(0)1909 550 885 | ||

| + | e-mail: info.uk@gea-ecoflex.com | ||

| + | |||

| + | Copper brazed plate heat exchanger model:- BP12M-20-G1G1 | ||

| + | |||

| + | ====Spec==== | ||

| + | Compact gasket-free Brazed Plate Heat Exchanger consisting of corrugated pressed stainles steel plates (1.4401), which are brazed together with copper in a special vacuum process. Designed, produced and tested in sites with quality systems in accordance with DIN ISO 9002 requirements. Pressure-Vessel Approval according TÜV and EC Pressure-Equipment-Directive (CE). | ||

| + | |||

| + | {| border=1; cellpadding=6 | ||

| + | !colspan=5|Specification for 1 x M12-20-GG | ||

| + | |- | ||

| + | !Operational data: | ||

| + | !Side A | ||

| + | | | ||

| + | !Side B | ||

| + | | | ||

| + | |- | ||

| + | |Media: | ||

| + | |Water | ||

| + | | | ||

| + | |Water | ||

| + | | | ||

| + | |- | ||

| + | |Condition: | ||

| + | |liquid | ||

| + | | | ||

| + | |liquid | ||

| + | | | ||

| + | |- | ||

| + | |Heat exchanged: | ||

| + | | | ||

| + | |50 | ||

| + | | | ||

| + | |kW | ||

| + | |- | ||

| + | |Mass flow: | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | | | ||

| + | |- | ||

| + | |Volume flow: | ||

| + | |0.64 | ||

| + | | | ||

| + | |0.24 | ||

| + | |l/s | ||

| + | |- | ||

| + | |Temperature inlet: | ||

| + | |82 | ||

| + | | | ||

| + | |10 | ||

| + | |°C | ||

| + | |- | ||

| + | |Temperature outlet: | ||

| + | |63 | ||

| + | | | ||

| + | |60 | ||

| + | |°C | ||

| + | |- | ||

| + | |Pressure drop: | ||

| + | |29.65 | ||

| + | | | ||

| + | |3.91 | ||

| + | |kPa | ||

| + | |- | ||

| + | |Surface margin: | ||

| + | | | ||

| + | |1.49 | ||

| + | | | ||

| + | |% | ||

| + | |- | ||

| + | |Content: | ||

| + | | | ||

| + | |0.5 | ||

| + | | | ||

| + | |l | ||

| + | |- | ||

| + | |Heat transfer area: | ||

| + | | | ||

| + | |0.22 | ||

| + | | | ||

| + | |m² | ||

| + | |- | ||

| + | |Design pressure: | ||

| + | | | ||

| + | |30 | ||

| + | | | ||

| + | |bar | ||

| + | |- | ||

| + | |Design temperature: | ||

| + | | | ||

| + | |200 | ||

| + | | | ||

| + | |°C | ||

| + | |} | ||

Revision as of 07:54, 17 March 2007

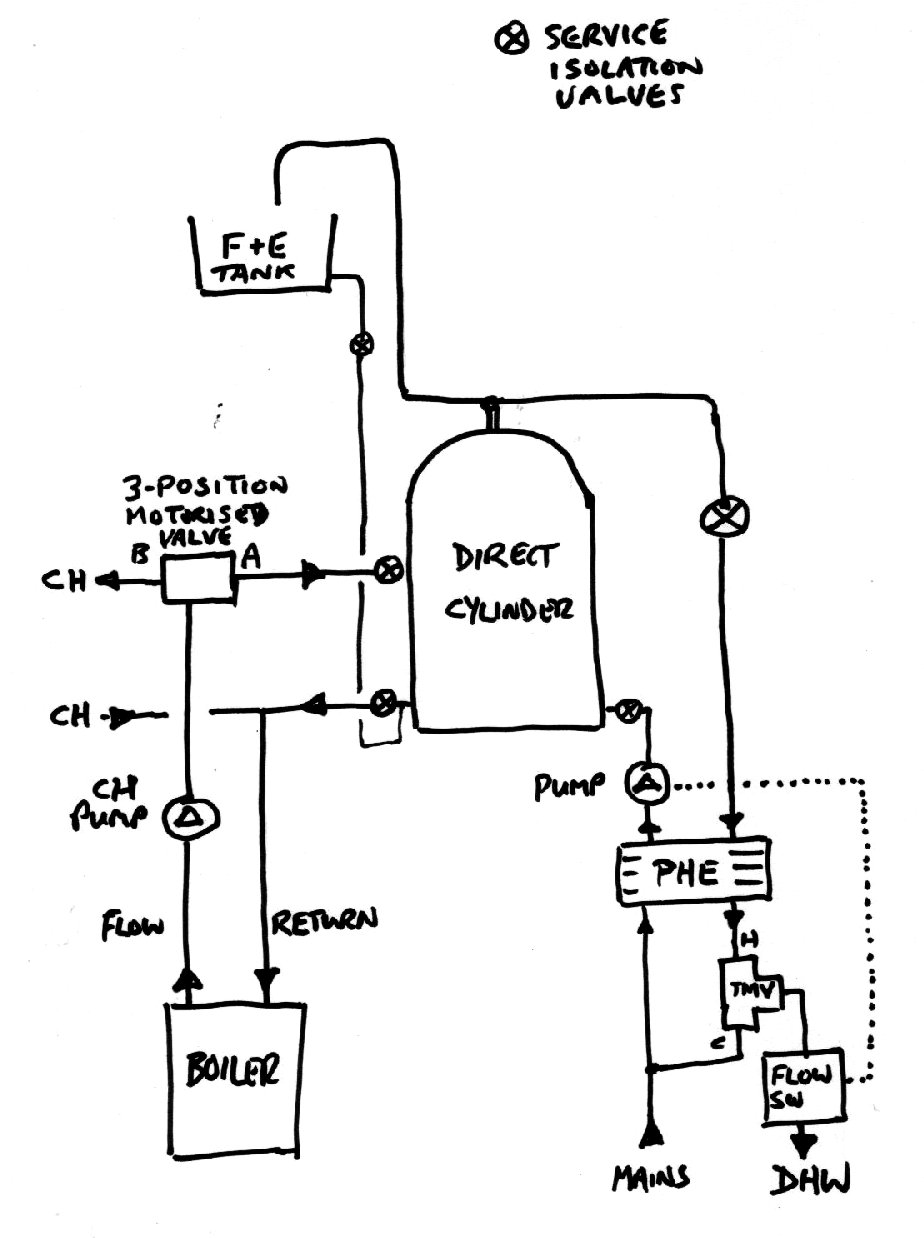

This article is about DIY Heat Banks.

Here's one we made earlier ...

Components

Normal Y-plan (or S-plan, W-plan etc) vented CH+DHW system with

- direct HW cylinder

- pump (CH circultor)

- Plate Heat Exchanger (PHE)

- Thermostatic Mixing Valve (TMV)

- Flow switch

PHE

From:

GEA-Ecoflex Unit 8, Waterside Business Park Redwall Close Dinnington-Sheffield S25 3QA Tel.: +44-(0)1909 551 107 Fax: +44-(0)1909 550 885 e-mail: info.uk@gea-ecoflex.com

Copper brazed plate heat exchanger model:- BP12M-20-G1G1

Spec

Compact gasket-free Brazed Plate Heat Exchanger consisting of corrugated pressed stainles steel plates (1.4401), which are brazed together with copper in a special vacuum process. Designed, produced and tested in sites with quality systems in accordance with DIN ISO 9002 requirements. Pressure-Vessel Approval according TÜV and EC Pressure-Equipment-Directive (CE).

| Specification for 1 x M12-20-GG | ||||

|---|---|---|---|---|

| Operational data: | Side A | Side B | ||

| Media: | Water | Water | ||

| Condition: | liquid | liquid | ||

| Heat exchanged: | 50 | kW | ||

| Mass flow: | ||||

| Volume flow: | 0.64 | 0.24 | l/s | |

| Temperature inlet: | 82 | 10 | °C | |

| Temperature outlet: | 63 | 60 | °C | |

| Pressure drop: | 29.65 | 3.91 | kPa | |

| Surface margin: | 1.49 | % | ||

| Content: | 0.5 | l | ||

| Heat transfer area: | 0.22 | m² | ||

| Design pressure: | 30 | bar | ||

| Design temperature: | 200 | °C | ||