DIY Heat Bank

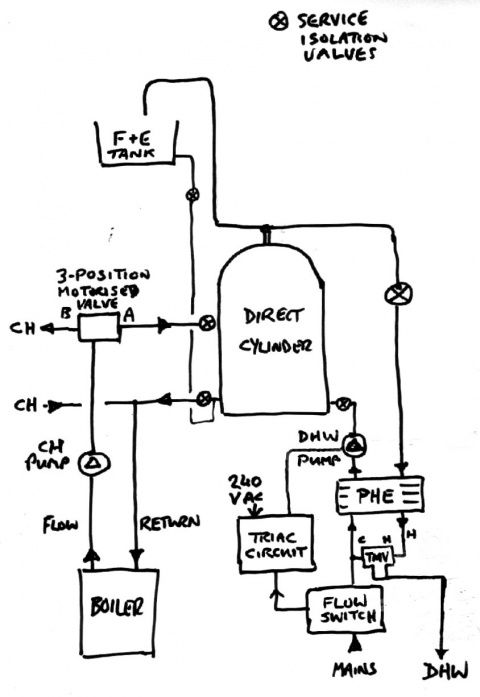

This article is about making a DHW Heat Bank using readily-available separate components.

Components

Normal Y-plan (or S-plan, W-plan etc) vented CH+DHW system with

- Direct HW cylinder (a standard Indirect cylinder could be used, either with extra tappings via e.g. Essex flanges, or Tee-ing the connections from the boiler into the top and (existing) bottom connections of the cylinder.)

- Pump (standard 15/50 CH circulator type)

- Plate Heat Exchanger (PHE)

- Thermostatic Mixing Valve (TMV) 22mm

- Flow switch wired to switch on pump when flow is detected

PHE

From:

GEA-Ecoflex Unit 8, Waterside Business Park Redwall Close Dinnington-Sheffield S25 3QA Tel.: +44-(0)1909 551 107 Fax: +44-(0)1909 550 885 e-mail: info.uk@gea-ecoflex.com

Copper brazed plate heat exchanger model:- BP12M-20-G1G1

Spec

Compact gasket-free Brazed Plate Heat Exchanger consisting of corrugated pressed stainles steel plates (1.4401), which are brazed together with copper in a special vacuum process. Designed, produced and tested in sites with quality systems in accordance with DIN ISO 9002 requirements. Pressure-Vessel Approval according TÜV and EC Pressure-Equipment-Directive (CE).

| Specification for 1 x M12-20-GG | ||||

|---|---|---|---|---|

| Operational data: | Side A | Side B | ||

| Media: | Water | Water | ||

| Condition: | liquid | liquid | ||

| Heat exchanged: | 50 | kW | ||

| Mass flow: | ||||

| Volume flow: | 0.64 | 0.24 | l/s | |

| Temperature inlet: | 82 | 10 | °C | |

| Temperature outlet: | 63 | 60 | °C | |

| Pressure drop: | 29.65 | 3.91 | kPa | |

| Surface margin: | 1.49 | % | ||

| Content: | 0.5 | l | ||

| Heat transfer area: | 0.22 | m² | ||

| Design pressure: | 30 | bar | ||

| Design temperature: | 200 | °C | ||

Note this is probably under-sized for this application: 100kW would be preferable.

Flow Switch

Farnell order code 730890 Manufacturer Part Number FS22 FLOW SWITCH, 22MM 3.75 L/MIN; Switch Poi £11.60 + VAT & p&p

This is a reed-switch whose contacts are rated 15VA, max 1A AC, into resistive loads.

The pump is rated 82W, 0.36A @ 230V AC and is an inductive load so the circuit shown is used to drive it.

----------+--- LIVE 240V AC

| |

| 100R

| |

------- === 0.1uF

| PUMP | | 600VDC

------- |

+----------

|

--100R-------+---------------

| | |

FLOW \ ------------ |

SW o | MT2 | |

| | | -----

------| G TRIAC | | MOV |

| | -----

| MT1 | |

------------ |

| |

+---------------

|

-------------- NEUTRAL

Triac: BTA16 600B (Maplin)

MOV 250V AC (Maplin)

Resistors 1W

Components wired up on strip of chock-block

- Discussion of design of circuit from sci.electronics.design

An alternative requiring no electronics would be to use a flow switch capable of switching the pump directly. These ara available from DPS.

TMV

This is a standard 22mm Thermostatic Mixing valve used for limiting the temperature of water to washbasins in hospitals, schools etc to prevent scalding. Available from Screwfix, Toolstation etc.

See Also

- Discussion: Home Made Heat Bank on uk.d-i-y

- Domestic Hot Water

- Domestic Hot Water Systems

- Thermal Stores and Heat Banks

- Central Heating