Large tenon jig

Introduction

This is a simple jig making project for your router. The large tenon jig is designed to allow you to cut large tenons with a router (e.g. the type used for making gates and doors), without being limited to a depth dictated by the length of your router cutter - as is the case with many traditional tenon jigs.

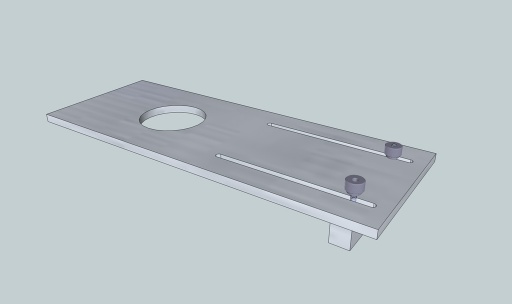

Construction

You will need a piece of sheet material approx 150mm wide, and say 450mm long. 9 - 12mm thick is ideal. You can use MDF, Ply, or ideally Acrylic for better visibility.

Start by cutting a clearance hole to match that in the base of your router. You can also mark out the positions of the fixing holes in your router base, and drill and countersink hole through the jig so that it can be fixed to the router.

Mill a couple of slots to allow the fixing and adjustment of the end stop / fence.

Make the fence from a small 130mm long block of wood say 25 x 19mm is cross section. Part drill a couple of clearance holes inthe base for the bolt heads, and then through drill for the bolt shafts.

Place the fence under the jig, feed the bolts through the fence and the jog, and screw down the hand tightened locking nuts.

In use

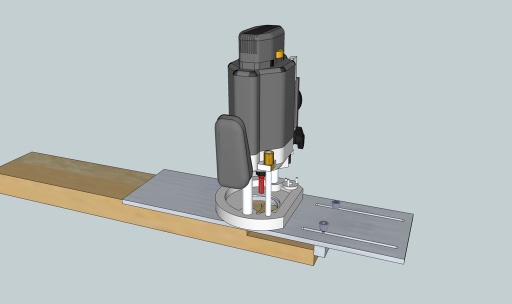

Fit a straight fluted cutter or rebating cutter to the router.

Mark out your tenon in the usual way. Offer the jig and router to the timber, and place parallel to the timber such that the edge of the cutter just reaches the shoulder of the tenon. Slide the fence up to the end of the timber and tighten the position.

Now slide the jig over so you can make a test plunge with the cutter beside the timber. Set the depth stop on the plunge so that the cutter just reaches the required depth of the tenon rebate.

Adjust the plunge to take your first pass, start the router, and make your first cut across the cull width of the timber adjacent to the shoulder. Keep a hand on the free end of the jig to hold it down flat on the work. Once the shoulder is cut, you can now cut away most of the rest of the tenon. Leave a little section at the far end to give more support to the jig though. Plunge deeper and repeat until the full depth is cut. Finally place a bit of scrap stock under the free fence end of the jig to add some support, and route away the end of the tenon, brining it down level with the rest.

Finally flip the timber over and repeat for the other side.