Difference between revisions of "Lighting Circuits Without an Earth"

(→Reducing risk: clarify re class II fittings) |

(→Extending the circuit: exaplain some more) |

||

| Line 34: | Line 34: | ||

===Extending the circuit=== | ===Extending the circuit=== | ||

| − | Not having | + | Not having an earth wire on a lighting circuit makes it impossible to extend the circuit for extra lighting points in a way that meets current wiring regulations. Extension can in principle be done safely if all switches, [[pattress]]es and lights are insulated, but regulations have demanded an earthed lighting circuit since 1966. |

| + | |||

| + | One viable workaround to add lighting points, is to feed them via another circuit that does have an earth wire. This can be another more recent lighting circuit, or can be a socket circuit via an fused connection unit (with appropriate [[fuse]]). | ||

===Consumer unit upgrades=== | ===Consumer unit upgrades=== | ||

Revision as of 23:19, 26 February 2011

Background

Many lighting circuits (usually installed pre 1966) are still in use that have no earth (aka Circuit Protective Conductor (CPC)). Whilst the rewiring of these circuits is the preferable solution, for many people the cost of installation and redecorating can be prohibitive.

Safety

Metal light fittings or switches on an unearthed circuit are a shock risk. If insulation fails, and that's not a rarity, the fitting will often become live. Touching that is a risk to life. One cause of insulation failure is buildup of dirt at conenction points, something that generally happens over the years.

Since unearthed lighting circuits are generally around half a century old, they tend to lack other safety features expected in a modern installation, some of which are very basic and necessary. These include:

1. Badly perished rubber insulation.

2. Light switches that can sit in mid position, and if luck deserts you, sit in an almost on position and arc. This either burns the switch out or causes a fire.

3. Non-EEBAD installation. Such installations can fail to blow a fuse when necessary, occasionally resulting in risk to life.

4. Dirt buildup at connection points. This can cause insulation breakdown, a fire & shock risk.

5. Poor connections. Connections can deteriorate due to decades of thermal cycling, wire corrosion, or lses than ideal fitting design & construction.

6. Flammable wiring enclosures, such as wooden pattresses behind light switches.

Reducing risk

If a rewire is not an option then the following steps should be taken for safety reasons

- Metal (Class I insulated) light fittings and metal accessories should be replaced with (Class II) fittings, which are either plastic, or metal and marked with the [[]] Class II symbol.

- Insulation Resistance Test. The circuit should be tested between the line conductor (line and neutral connected together) and the earth terminal of the consumer unit. The resistance should be at least 1 Megohm. If the resistance is less that 1 Megohm the circuit must have additional RCD protection. The test should also be repeated between the line conductor and any exposed conductive part of the circuit (eg the screws for a lightswitch with a metal backbox). Again if the readings are less than 1 Megohm then additional RCD protection will be required.

- RCD protection. It is advisable to have 30mA RCD protection on lighting circuits that have no cpc and essential if the resistance readings are lower than 1 Megohm.

- 2 and 3 pin sockets. Any 2 or 3 pin sockets connected to the lighting circuit that may be used for portable equipment should be disconnected.

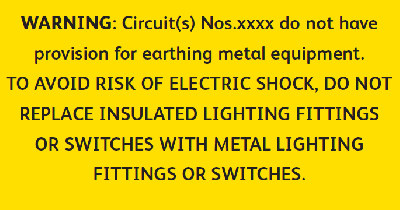

- A warning notice similar to the one below should be fixed on or adjacent to the CU or fusebox:

Potential problems

Extending the circuit

Not having an earth wire on a lighting circuit makes it impossible to extend the circuit for extra lighting points in a way that meets current wiring regulations. Extension can in principle be done safely if all switches, pattresses and lights are insulated, but regulations have demanded an earthed lighting circuit since 1966.

One viable workaround to add lighting points, is to feed them via another circuit that does have an earth wire. This can be another more recent lighting circuit, or can be a socket circuit via an fused connection unit (with appropriate fuse).

Consumer unit upgrades

Many electricians may also refuse to swap a fusebox for a CU unless the old lighting circuit is also rewired.