Introduction

The oscillating tool or "multitool", is a concept that was originally made popular by the German manufacturer Fein with their Multimaster range of tools. In recent years, a number of similar tools based on the multimaster concept have become available. This article serves not only as a FAQ for this particular class of tool, it also documents the level of interoperability between the blades and accessories for the various makes.

What is it?

Its a small versatile tool designed to perform a wide range of tasks. They can be used for cutting, sanding, rasping, polishing, scraping and a number of other tasks. They make very effective tools for performing awkward cutting operations that are almost impossible with any other tool.

Tools on the market are available in both mains-operated and cordless (Li-Ion powered) models, at a wide range of price points.

How does it work?

An oscillating tool, looks a little reminiscent of a detail sander, and in fact they do make very good detail sanders. However that is where the similarity ends. Rather than having a fixed sanding pad that orbits, they have a tool attachment post. The various tools are then firmly bolted or clipped to the post. When running, the tool post rotates a very small amount in alternate directions, at a very high frequency (typically 20,000 oscillations per minute).

Its this oscillation that does the actual work. The end of a saw blade for example will swing back and fourth by a couple of millimetres. With its fine teeth, this is enough to cut any rigidly held material it comes into contact with. An abrasive will similarly work back and forth over a surface.

What can it do?

One of the unique abilities of this type of tool is the way in which it can cut. Equipped with the appropriate blade it can simply plunge into the surface of the material that is being cut, without touching or damaging anything adjacent to the thing being cut. Unlike for example plunge cutting with a chisel, the cut has a very fine kerf. This makes it ideal for a number of jobs:

- Cutting floorboards prior to lifting - precise neat cuts can be plunged into a board directly above a joist with no risk to pipes or cables under the floor.

- Flush cutting; many of the blades include an offset or "crank" that enables them to cut flush with a surface. This is ideal for cropping pipes against a wall, or undercutting a door frame to allow a wood floor to slide under the jamb. Undercutting skirting.

- Cutting objects, such as pipework, in confined spaces e.g. cutting copper pipe where there is insufficient access for a pipeslice, hacksaw, sabre saw etc: one can even cut a section out of a damaged pipe in an excavated chase.

- Cutting grout out from between ceramic wall tiles (either using a grit-edged blade or an old wood or metal blade) to pry away a single tile (or small group of tiles) for access or repair.

- Sanding, scraping, polishing etc

- Rasping - a carbide rasp will quickly eat through rotten wood, tile glue residue, old putty etc.

Who will find a use for one?

Anyone doing general DIY, Handymen, Tilers, Glazers, Plumbers, Electricians.

Disadvantages

Blades can be expensive, and they can be relatively fragile - for example hitting masonry with a timber cutting blade will frequently damage it.

They are also relatively slow cutting - typically favouring fine teeth and small amounts of cutting movement, they will cut slower than a jigsaw or circular saw for example.

Safety

Multitools are one of the safer power tools to use. When fitted with a saw blade, they are unlikely cut human flesh even if deliberately applied to the skin, this is because the skin simply tends to vibrate and move with the blade rather than being torn by it (although skin pulled tight over a bone etc may be more vulnerable). Note that the tools used in hospitals for removing plaster casts often use the same oscillating cutting technique.

When sanding, one must still take adequate protection from the dust.

Ear protection is also advised for prolonged use, since they produce a fairly loud noise with much of the sound concentrated into a narrow frequency band that quickly dulls the hearing.

The Tools

| Oscillating tool blades

|

(universal mounting)

|

A narrow plunge cut blade for wood and plastics etc. Ideal for floorboard lifting, cutting holes for electrical back boxes in plasterboard etc. This one is a "Bi-metal" type that can be used on composites and some non ferrous metals.

|

(universal mounting)

|

A wide plunge cut blade for wood and plastics etc. Uses as above - but for wider cuts.

|

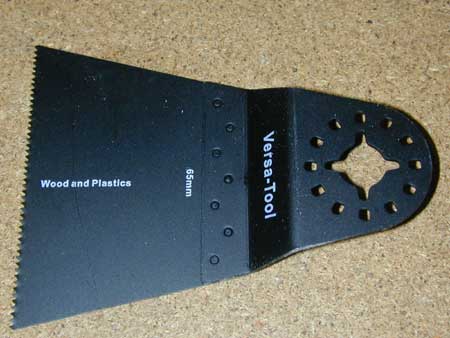

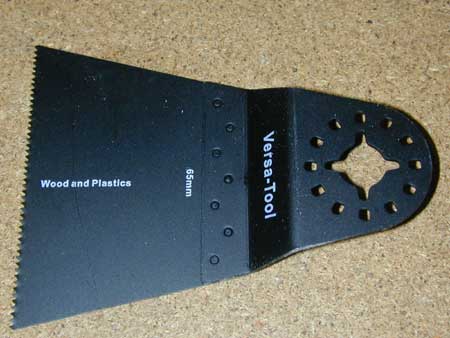

(universal mounting)

|

This is a wood and plastics cutting plunge cutting blade. This one has larger more aggressive teeth for fast cutting. These are best suited to cutting things that are well supported and fixed, like floorboards since otherwise they tend to just catch and vibrate the work!

|

(Fein mounting)

|

A Sharp untoothed scraper blade. These are designed for getting under sticky stuff - scraping glue residue, or adhesive backed plastics off hard surfaces.

|

(Fein mounting)

|

A hook and loop sanding backing pad designed for the felt backed sanding pads. Note that unlike traditional delta pads these have a slight radius to each side that matches the arc of rotation of the machine. This enables you to sand right up to an adjacent surface with no risk of straying onto it, or hammering against an edge as you would with a traditional delta sander.

|

(Fein mounting)

|

A vented version of the sanding pad designed for use with vacuum extraction.

|

|

The original Multimaster and many of the clones don't have any built in ducting for dust extraction. They typically have an additional cowl that fits against the side of the machine and under the tool post. A felt washer maintains a close seal between the cowl and the back of the sanding pad. While no sander has perfect dust collection, this is one of the more effective collection systems you will encounter. Mess is also reduced since the oscillating action tends to drop the dust straight down rather than throwing it into the air as much as other sanding actions.

|

(universal mounting)

|

This is a depressed centre HSS segment saw for cutting woods, composite, and metals. The depressed centre will allow flush cutting, and the segment allows you to cut up to neat finish at an edge without the traditional overcut one associates with a circular blade. Note that one is better off using a round blade if this close cutting facility is not required, since the teeth near the segment will tend to wear first, and this is the most useful bit of the blade.

|

(universal mounting)

|

This is a flat version of the above. The flat blade can't cut flush to a surface, but can in some cases cut a little deeper. These blades are often a little cheaper than the depressed centre versions.

|

(universal mounting)

|

A circular HSS blade. Ideal for general cutting from any part of the blade. Note that since the tool does not rotate the blade in use, it is worth rotating it manually from time to time to spread the tooth wear around all the teeth.

|

(Fein mounting)

|

Even broken blades can be worth keeping if the mounting part is still serviceable!

|

|

Wrap a bit of sandpaper round a multitool blade and secure with a dab of superglue. Makes a detail sanding finger that will reach into places other sanding solutions can't reach!

|

(Fein mounting)

(Fein mounting)

|

A carbide edged segment saw. These are ideal for cutting ceramics, glass, cast iron and other hard materials. Particularly good for neatly cutting holes in the middle of tiles or tiles that are already fixed to the wall - say when cutting in electrical accessory boxes, or making access to shower valves. They are also very effective for removing old grout from between tiles. For even longer life, there are diamond versions of these available.

|

(Fein mounting)

|

The carbide rasp is also a very handy tool for tilers, It allows the quick and effective removal of old set tile adhesive for example. Combined with this and the carbide segment saw, removing broken or damaged tiles for replacement becomes very straightforward.

The rasp is also effective at removing badly flaked old paint, or putty residue from window frames when re-glazing.

Can be used on wood for coarse shaping, or for quickly removing rotten wood from window frames etc prior to filling.

|

(Fein mounting)

|

This is an adaptor blade designed for holding mini blades and rasps. These are aimed at detail work, and are handy for activities such as model making, and sharpening of small tools.

|

|

A variety of blades and rasps for use with the above tool holder.

|

Tool Interchangeability

One of the disadvantages of oscillating tools is the cost of the blades, combined with the fact they are easily damaged if not treated with care (attempting to plunge a wood blade against a nail or masonry for example will very quickly reduce it to something that ceases cutting wood and attempts to burn its way though!

The rise in availability of similar tools however has meant that blade prices have fallen, and there there are new sources of blades. Hence the question arises regarding blade interchangeability.

Most brands produce the basic plunge cutting and scraping blades. Many also have the carbide blades. However Fein still produce the widest range of blades with some very specialist blades as well as the more run of the mill ones.

Initial reports seem to suggest that blade quality is generally good, regardless of the source.

| Machine

|

Blade Mounting

|

| Original Fein Multimaster

|

The original Multimaster used a basic screw fixing for the blades without any further registration lugs or pins. The blades simply had a 10mm mounting hole that sat over the flange on the tool post, and the fixing screw with clamp plate tightended down onto them. This system allowed the blade to be installed at any angle. However it does require the screw to be securely done up with the supplied allen wrench, or the blade position can wander in use.

One advantage of the earlier Fein machine mounting is that it allows use of all the various blade designs available.

|

| Current Multimaster

|

The current models use a quick release blade fixing system that retains a stud with a lever action mechanism. The tool post also has registration lugs that engage with notches cut around the periphery of the main 10mm mounting hole. Hence the new machines can use Fein blades, and universal blades.

|

| Bosch Multitool

|

Bosch do a couple of tools, a green bodied DIY class machine that is mains powered, and a blue "pro" range cordless tool. These have a ring of registration pins that match the Bosch blade patten:

Bosch tools can hence use Bosch blades and universal blades.

|

| Ferm, Powercraft (Aldi)

|

The Ferm and Aldi Powercraft branded tool has a similar arrangement to the Bosch system but with fewer pins:

As a result these tools can use their own branded blades, as well as Bosch, and universal ones.

|

| Rockworth (Makro and other places)

|

These relatively low cost tools use the same mounting as the original Fein multimaster. Hence can use any blades.

|

| Universal Adaptor

|

Bosch have also produced this little adaptor - it supposedly allows Bosch blades to fit on any machine! (it may also allow other blades to be used more interchangeably (yet to be confirmed!)

|

Blade Sharpening

Steel oscillating tool blades are easy to resharpen. A flat file gets all the tooth tips the same height, then a triangular file cuts the spaces between the teeth.

See also