Difference between revisions of "Single Shot heater control"

m (Implementation notes) |

m (→Principle of operation: slight re-word) |

||

| (4 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

There may be times where you need single shot control for a heater. The principle being that you can start the heating with the push of a button, and it will then run until a set temperature is reached, before shutting off completely until the next time it is manually started. | There may be times where you need single shot control for a heater. The principle being that you can start the heating with the push of a button, and it will then run until a set temperature is reached, before shutting off completely until the next time it is manually started. | ||

| + | == Hot water cylinder controls == | ||

| + | The following circuits describe single shot controls for use with domestic hot water cylinders heated by an immersion heater. They make use of either a separate cylinder thermostat or the internal thermostat present in the heater itself. The designs could be re-purposed for other single shot heating applications, but would need a different type of thermostat. | ||

| + | |||

| + | === Option 1 === | ||

[[File:Single Shot Heater Control.png|alt=Single Shot Control used with an immersion heater and cylinder stat]] | [[File:Single Shot Heater Control.png|alt=Single Shot Control used with an immersion heater and cylinder stat]] | ||

| − | === Parts required === | + | ==== Parts required ==== |

# A mains double pole relay, with a 230V coil, and contacts rated for a load of at least 13A | # A mains double pole relay, with a 230V coil, and contacts rated for a load of at least 13A | ||

| − | # A momentary action or "Push to Make" press switch | + | # A momentary action or "Push to Make" press switch rated at at least 8A |

# A normal "strap on" cylinder thermostat. | # A normal "strap on" cylinder thermostat. | ||

| − | === Principle of operation === | + | ==== Principle of operation ==== |

Pushing the spring return push to make "on" switch energises the relay which closes its contacts This powers the heater. | Pushing the spring return push to make "on" switch energises the relay which closes its contacts This powers the heater. | ||

| Line 16: | Line 20: | ||

The system will now stay in the heating state until the cylinder stat is satisfied, and opens its contacts. This will de-energise the coil, turning everything off. | The system will now stay in the heating state until the cylinder stat is satisfied, and opens its contacts. This will de-energise the coil, turning everything off. | ||

| − | Feeding the cylinder stat via a second set of contacts makes sure that there is no time where the heater could attempt to draw a high current through the contacts of either the on switch or the cylinder stat. | + | Feeding the cylinder stat via a second set of contacts makes sure that there is no time where the heater could attempt to draw a high current solely through the contacts of either the on trigger switch or the cylinder stat. |

| − | === Implementation === | + | ==== Implementation ==== |

Note that earth connections are omitted from the diagram for clarity, but should be included. Mains filter networks could also be included across the relay coil to reduce mains interference created by switching inductive coils. See this article on [[Extractor fan wiring#Using relay controls|using relay controls]] | Note that earth connections are omitted from the diagram for clarity, but should be included. Mains filter networks could also be included across the relay coil to reduce mains interference created by switching inductive coils. See this article on [[Extractor fan wiring#Using relay controls|using relay controls]] | ||

| Line 25: | Line 29: | ||

'''IMPORTANT:''' The temperature on the internal immersion thermostat '''must''' to be set '''higher''' than that set on the cylinder thermostat, otherwise the circuit will never be able to reach the selected final temperature, and will never turn off. | '''IMPORTANT:''' The temperature on the internal immersion thermostat '''must''' to be set '''higher''' than that set on the cylinder thermostat, otherwise the circuit will never be able to reach the selected final temperature, and will never turn off. | ||

| + | === Option 2 === | ||

| + | The following implementation does away with the external cylinder thermostat, and uses the internal immersion thermostat to end the heating cycle. It can also operate with a single pole relay. This is cheaper to implement, but has a couple of limitations. The first is that the "on" switch will need to be rated to take the full load current of the immersion heater, since it will briefly be the sole source of power to the heater. Also operation will stop the first time the immersion stat is activated. Normally this should be ok, however in some cases with well stratified cylinders, or immersion elements that are covered in hard water scale, you may not get a complete cylinder re-heat. | ||

| + | |||

| + | [[File:Single Shot Heater Control - no stat.png]] | ||

| + | |||

| + | ==== Parts required ==== | ||

| + | # A mains relay, with a 230V coil, and contacts rated for a load of at least 13A | ||

| + | # A momentary action or "Push to Make" press switch with contacts rated for a load of at least 13A | ||

| + | |||

| + | ==== Implementation ==== | ||

| + | Note that earth connections are omitted from the diagram for clarity, but should be included. Mains filter networks could also be included across the relay coil to reduce mains interference created by switching inductive coils. See this article on [[Extractor fan wiring#Using relay controls|using relay controls]]. Note that the connection to the live side of the relay coil must be taken from the connection on the immersion heater that joins the output of the thermostat to the input of the heater - not from the mains input to the whole heater. Note that some thermostats completely cover the terminals of the heater element itself, this may make access difficult. | ||

| + | |||

| + | ==== Principle of operation ==== | ||

| + | Similar to the first circuit, although this time the relay coil is wired in parallel to the immersion heater, so that any time it is powered, the relay will be energised. The internal thermostat is connected in series with the immersion heater in the normal way, however an additional connection wire will need to be taken from the connection shared between the thermostat and the heater element to provide the live connection to the relay. '''This is important, since without this connection from this position there will be no way to turn the circuit off when the thermostat is satisfied'''. | ||

[[Category:Electrical]] | [[Category:Electrical]] | ||

[[Category:Heating]] | [[Category:Heating]] | ||

| + | [[Category:Domestic Hot Water]] | ||

Latest revision as of 11:29, 19 November 2021

There may be times where you need single shot control for a heater. The principle being that you can start the heating with the push of a button, and it will then run until a set temperature is reached, before shutting off completely until the next time it is manually started.

Hot water cylinder controls

The following circuits describe single shot controls for use with domestic hot water cylinders heated by an immersion heater. They make use of either a separate cylinder thermostat or the internal thermostat present in the heater itself. The designs could be re-purposed for other single shot heating applications, but would need a different type of thermostat.

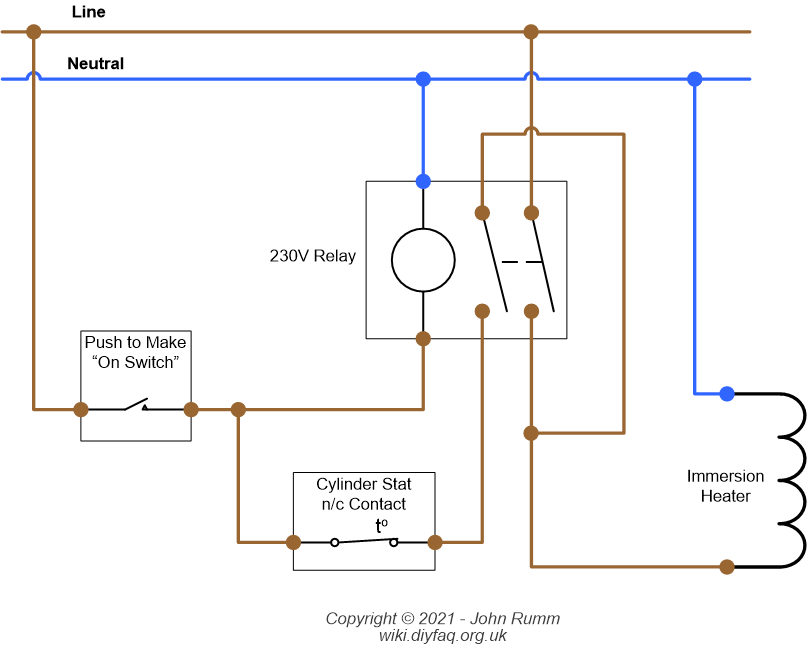

Option 1

Parts required

- A mains double pole relay, with a 230V coil, and contacts rated for a load of at least 13A

- A momentary action or "Push to Make" press switch rated at at least 8A

- A normal "strap on" cylinder thermostat.

Principle of operation

Pushing the spring return push to make "on" switch energises the relay which closes its contacts This powers the heater.

A feedback is taken from the relay's switched live output back to the input of the the second set of contacts. The output from this set is connected via the normally closed contacts of a cylinder stat to the coil of the relay. This is used to "hold on" the relay, allowing the heater to remain on after the push to make on switch is released.

The system will now stay in the heating state until the cylinder stat is satisfied, and opens its contacts. This will de-energise the coil, turning everything off.

Feeding the cylinder stat via a second set of contacts makes sure that there is no time where the heater could attempt to draw a high current solely through the contacts of either the on trigger switch or the cylinder stat.

Implementation

Note that earth connections are omitted from the diagram for clarity, but should be included. Mains filter networks could also be included across the relay coil to reduce mains interference created by switching inductive coils. See this article on using relay controls

Note most immersion heaters include their own thermostat, it is better to leave this with direct control of the element, and rely on the external cylinder stat to control the "single shot" system. That will allow the internal immersion stat to cycle if required (say when operating with a scaled up heating element), without tripping off the heating cycle before the whole cylinder is at the desired set temperature.

IMPORTANT: The temperature on the internal immersion thermostat must to be set higher than that set on the cylinder thermostat, otherwise the circuit will never be able to reach the selected final temperature, and will never turn off.

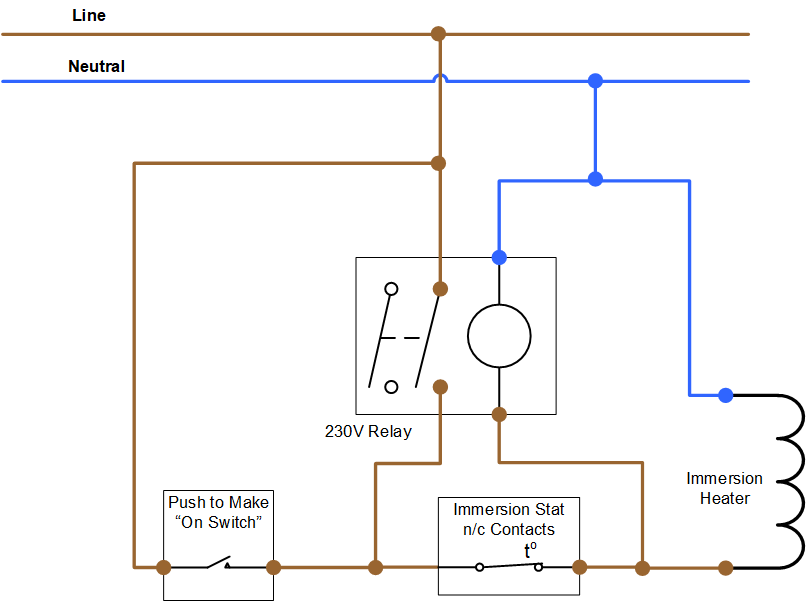

Option 2

The following implementation does away with the external cylinder thermostat, and uses the internal immersion thermostat to end the heating cycle. It can also operate with a single pole relay. This is cheaper to implement, but has a couple of limitations. The first is that the "on" switch will need to be rated to take the full load current of the immersion heater, since it will briefly be the sole source of power to the heater. Also operation will stop the first time the immersion stat is activated. Normally this should be ok, however in some cases with well stratified cylinders, or immersion elements that are covered in hard water scale, you may not get a complete cylinder re-heat.

Parts required

- A mains relay, with a 230V coil, and contacts rated for a load of at least 13A

- A momentary action or "Push to Make" press switch with contacts rated for a load of at least 13A

Implementation

Note that earth connections are omitted from the diagram for clarity, but should be included. Mains filter networks could also be included across the relay coil to reduce mains interference created by switching inductive coils. See this article on using relay controls. Note that the connection to the live side of the relay coil must be taken from the connection on the immersion heater that joins the output of the thermostat to the input of the heater - not from the mains input to the whole heater. Note that some thermostats completely cover the terminals of the heater element itself, this may make access difficult.

Principle of operation

Similar to the first circuit, although this time the relay coil is wired in parallel to the immersion heater, so that any time it is powered, the relay will be energised. The internal thermostat is connected in series with the immersion heater in the normal way, however an additional connection wire will need to be taken from the connection shared between the thermostat and the heater element to provide the live connection to the relay. This is important, since without this connection from this position there will be no way to turn the circuit off when the thermostat is satisfied.