Difference between revisions of "Unvented DHW"

m (→Checking and re-pressurising the expansion vessel: reword in English this time!) |

|||

| (19 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

| − | Like a conventional hot water cylinder fed from a tank in the roof, an unvented cylinder contains hot water (heated by a boiler or immersion heater) which directly supplies the hot taps. Unlike a conventional cylinder | + | Like a conventional hot water cylinder fed from a tank in the roof, an unvented cylinder contains hot water (heated by a boiler or immersion heater) which directly supplies the hot taps. Unlike a conventional cylinder however, the water in the unvented cylinder comes directly from the cold water main, and is at (or nearly at) mains pressure. |

| − | To contain this pressure the cylinder has to be physically much stronger than in | + | To contain this pressure the cylinder has to be physically much stronger than those used in gravity-fed systems. Unvented cylinders are made of thicker copper or stainless steel, and are usually more expensive than cylinders designed for vented operation. |

| + | |||

| + | This article describes a typical unvented cylinder installation of a size appropriate for meeting the hot water needs of a domestic property. There are some small unvented cylinders on the market (with a water capacity of 15 litres or less) designed for just providing hand wash facilities. These are in some circumstances subjected to fewer regulations and less complex system installation requirements. However they are not the primary focus of this article. | ||

| + | |||

| + | Any unvented hot water heater installation connected to the public water supply has to comply with the [http://www.legislation.gov.uk/uksi/1999/1148/contents/made Water Supply (Water Fittings) Regulations 1999] and more widely, a pressurised unvented water heater also has to be installed in accordance with The [https://www.planningportal.co.uk/info/200135/approved_documents/69/part_g_-_sanitation_hot_water_safety_and_water_efficiency Building Regulations (2016) Document G] and [https://www.planningportal.co.uk/info/200135/approved_documents/71/part_h_-_drainage_and_waste_disposal Document H (2015)] | ||

==Considerations for installation== | ==Considerations for installation== | ||

| − | When | + | When installed in appropriate situations, unvented cylinders are good at providing high flow rates of hot water, and can have the capacity for larger properties with multiple baths and showers. Hot water is supplied at (or near) mains pressure, and will drive showers without the need of additional pumps. |

When considering an unvented cylinder, there are several factors to check first. Failure to do this could result in unsatisfactory performance, or a system not well suited to the actual requirements. | When considering an unvented cylinder, there are several factors to check first. Failure to do this could result in unsatisfactory performance, or a system not well suited to the actual requirements. | ||

| Line 10: | Line 14: | ||

To function well, you need adequate mains pressure and an adequate flow rate (these are not the same thing). Ideally your mains pressure should be in the range of 2 - 10 bar (systems with less pressure may still work, but you will lose performance, and may find you get better results with a conventional header tank). | To function well, you need adequate mains pressure and an adequate flow rate (these are not the same thing). Ideally your mains pressure should be in the range of 2 - 10 bar (systems with less pressure may still work, but you will lose performance, and may find you get better results with a conventional header tank). | ||

| − | The mains flow rate should be a '''minimum''' of 20 lpm | + | The mains flow rate should be a '''minimum''' of 20 Litres Per Minute (lpm) - (although more is better). The mains supply will need to meet all the household demands concurrently - hot and cold. |

==Advantages of Unvented cylinders== | ==Advantages of Unvented cylinders== | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | :[1] i.e. water at | + | *Mains pressure hot water to all outlets |

| + | *High flow rates of hot water at "mix temperature" [1], ideal for properties with multiple showers / baths | ||

| + | *Fast reheat [2] | ||

| + | *No requirement for a header tank in the loft | ||

| + | *Work well in properties without adequate height available for gravity fed systems (flats, chalet style houses etc) | ||

| + | *Can be heated by multiple sources, e.g. gas boiler, immersion heater, solar collector. | ||

| + | |||

| + | :[1] i.e. Water that is supplied to the outlet hotter than is required so that it can be mixed with cold before use. This means the hot supply does not need to supply water at the full rate of use and hence there will have more spare capacity. | ||

:[2] Most cylinders are equipped with large high efficiency indirect coil heat exchangers that can transfer heat at over 20kW (if the boiler is capable of supplying it). The reheat time of electric only cylinders will be dependant on the number and power of immersion heaters fitted. | :[2] Most cylinders are equipped with large high efficiency indirect coil heat exchangers that can transfer heat at over 20kW (if the boiler is capable of supplying it). The reheat time of electric only cylinders will be dependant on the number and power of immersion heaters fitted. | ||

==Disadvantages== | ==Disadvantages== | ||

| − | * More complex controls required than with a conventional vented system or combination boiler | + | |

| − | * More expensive component costs (although total system price may be similar depending on the labour required) | + | *More complex controls required than with a conventional vented system or combination boiler |

| − | * Need an adequate and reliable mains water supply (they can't supply water without a mains feed) | + | *More expensive component costs (although total system price may be similar depending on the labour required) |

| − | * Need annual servicing, possibly incurring extra cost | + | *Need an adequate and reliable mains water supply (they can't supply water without a mains feed) |

| − | * Can't be heated by solid fuel stoves etc. | + | *Need annual servicing, possibly incurring extra cost |

| + | *Can't be heated by solid fuel stoves etc. | ||

| + | |||

| + | ==Selecting cylinder size== | ||

| + | Typical unvented domestic cylinders start at around 125L and many makers do a range of sizes up to 300L or more. The smaller sizes being adequate for properties that have a single shower/bathroom. Larger sizes become more appropriate for larger properties with more baths and showers to cater for. Specifying the "right" size is not an exact science. See the [[Sizing a hot water cylinder]] article for more details. | ||

==The components of an unvented cylinder== | ==The components of an unvented cylinder== | ||

| Line 34: | Line 43: | ||

[[image:TypicalUnventedCylinder.png]] | [[image:TypicalUnventedCylinder.png]] | ||

| + | [[image:UnventedCylinderMFValveLabel.png|right|thumb|caption|Example Multifunction Valve as fitted to a Unistor Cylinder. Showing the equivalent parts as shown in the main diagram (note this valve has no secondary return connection since that is fitted to the cylinder itself)]] | ||

| − | # Temperature and pressure relief valve | + | #Temperature and pressure relief valve |

| − | # Expansion relief valve | + | #Expansion relief valve |

| − | # Pressure limiting valve (usually combined with a filter / strainer) | + | #Pressure limiting valve (usually combined with a filter / strainer) |

| − | # Connection for a secondary return (often provided by an extra tapping on the cylinder) | + | #Connection for a secondary return (often provided by an extra tapping on the cylinder) |

| − | # Balanced pressure cold water outlet | + | #Balanced pressure cold water outlet |

| − | # Main cold supply inlet | + | #Main cold supply inlet |

| − | # Outlet to DHW | + | #Outlet to DHW |

| − | # Tundish | + | #Tundish [1] |

| − | # Drain Point | + | #Drain Point |

| − | # Expansion Vessel | + | #Expansion Vessel |

Connections to the primary heating flow and return are shown to the left (with two port zone valve). | Connections to the primary heating flow and return are shown to the left (with two port zone valve). | ||

| + | |||

| + | [[image:Tundish15mm.png|200px]] | ||

| + | |||

| + | [1] A tundish (pictured above) is a device that introduces a visible air break into a pipe. In an unvented DHW system it serves two purposes; Firstly it adds to the protection of incoming public water main, reducing further the possibility of contamination from your hot water system, secondly, it gives a visible indication of any water being released from any of the safety valves fitted to the system. | ||

| + | |||

===Valves=== | ===Valves=== | ||

| − | |||

| − | |||

| − | ( | + | *A check valve (which is usually implemented as part of the pressure reduction valve). |

| + | *A pressure reduction valve typically set to around 3 bar (although other pressures are sometimes used). | ||

There may also be a cold water outlet point after the pressure reducing valve to supply e.g. shower mixing valves which work better when their hot and cold supplies are at the same pressure. | There may also be a cold water outlet point after the pressure reducing valve to supply e.g. shower mixing valves which work better when their hot and cold supplies are at the same pressure. | ||

| − | * A pressure relief valve (typically set to 6 bar), this is mounted on the inlet to the cylinder. | + | *A pressure relief valve (typically set to 6 bar), this is mounted on the inlet to the cylinder. |

The above items are often found combined into a single multifunction unit. | The above items are often found combined into a single multifunction unit. | ||

| − | * A combined over pressure and temperature relief valve. This is always on the side of the cylinder. It will typically be set to 7 bar and 90C. The thread that is used for this fitting is unique to this type of device to avoid the hole being used for any other purpose and so that the only way to block the hole is to install the valve. | + | *A combined over pressure and temperature relief valve. This is always on the side of the cylinder. It will typically be set to 7 bar and 90C. The thread that is used for this fitting is unique to this type of device to avoid the hole being used for any other purpose and so that the only way to block the hole is to install the valve. |

| − | (The reason for the ''temperature'' limiting valve in addition to a pressure limiting one is so that if a heating source fails to cut out, it is possible for the pressure rise will remain quite modest until the water reaches well over 100C (even 1 bar will raise the boiling point to around 120C). So neither pressure relief valve would open and yet the contents of the cylinder would be lethal and will 'flash' boil to steam when pressure in the system is reduced by opening a tap. Should this valve operate, it will dump some | + | (The reason for the ''temperature'' limiting valve in addition to a pressure limiting one is so that if a heating source fails to cut out, it is possible for the pressure rise will remain quite modest until the water reaches well over 100C (even 1 bar will raise the boiling point to around 120C). So neither pressure relief valve would open and yet the contents of the cylinder would be lethal and will 'flash' boil to steam when pressure in the system is reduced by opening a tap. Should this valve operate, it will dump some of the contents of the cylinder (containing water at 90C!) into the relief discharge pipework. The valve will only close when cooler water from the mains supply has reached it. This is also why there are stringent requirements for the size, length and routing of the discharge pipe. |

===Thermal Cutouts=== | ===Thermal Cutouts=== | ||

| Line 70: | Line 84: | ||

===Discharge Pipe=== | ===Discharge Pipe=== | ||

| − | The pressure relief and over temperature valves discharge into an emergency relief discharge pipe. They are usually combined and connected to a tundish, which in turn feeds the discharge pipe. The tundish provides an air gap required between anything connected directly to a mains water supply, and a drain so as to prevent any possibility of back contamination of the mains supply. It also provides a visible indication of any loss of water via the safety valves. The discharge pipe must be metallic (or certified as capable of handling a significant flow of near boiling water) and of at least 22mm diameter. | + | The pressure relief and over temperature valves discharge into an emergency relief discharge pipe complying with Water Regulations Section 8 Schedule 2 G19 ''Discharge pipes from safety devices''; G19.1; G19.3; & G19.4. They are usually combined and connected to a tundish complying with ''WRAS test code sheet number 221210'', which in turn feeds the discharge pipe. The tundish provides an air gap required between anything connected directly to a mains water supply, and a drain so as to prevent any possibility of back contamination of the mains supply to comply with Water Regulations section 6.3 – ''Regulator’s specification for backflow prevention arrangements and devices for the requirement for fittings'' – and section 6.4 ''Guidance clauses related to schedule 1 : Fluid categories''; and Paragraph 15 of ''Schedule 2: Backflow prevention''. It also provides a visible indication of any loss of water via the safety valves. The discharge pipe must be metallic (or certified as capable of handling a significant flow of near boiling water) and of at least 22mm diameter. |

[[image:UnventedDischargePipe.png]] | [[image:UnventedDischargePipe.png]] | ||

| Line 76: | Line 90: | ||

The maximum effective length of pipe from the tundish is also specified: | The maximum effective length of pipe from the tundish is also specified: | ||

| − | {| | + | {| style="text-align:center" cellspacing="0" cellpadding="6" border="1" |

|- | |- | ||

| − | ! Minimum size of discharge | + | !Minimum size of discharge |

pipe pipework from tundish | pipe pipework from tundish | ||

| − | ! Maximum effective | + | !Maximum effective |

length | length | ||

| − | ! Effective length of | + | !Effective length of |

each elbow or bend | each elbow or bend | ||

|- | |- | ||

| − | | 22mm || 9m || 0.8m | + | |22mm||9m||0.8m |

|- | |- | ||

| − | | 27mm || 18m | + | |27mm||18m||1.0m |

|- | |- | ||

| − | | 35mm || 27m | + | |35mm||27m||1.4m |

|} | |} | ||

| − | There must be a vertical drop of pipe after the tundish (minimum length of 300mm) before any bends. The discharge pipe must terminate outside of the building in a safe place such as a gully where it can't cause injury | + | There must be a vertical drop of pipe after the tundish (minimum length of 300mm) before any bends. The discharge pipe must terminate outside of the building in a safe place such as a gully where it can't cause injury (Building Regulations G3 (3)(b)) (other discharge positions may be acceptable so long as measures are taken to minimise risk of injury to bystanders). In blocks of flats and similar, an internal discharge to the soil waste may be used providing precautions are taken against back-contamination (Building regulations H1 Guidance: c). The [https://hotun.co.uk/hotun-dry-trap-solution-for-large-unvented-water-heaters/ Hotun dry trap tundish] may be used in such circumstances. |

===Expansion vessel=== | ===Expansion vessel=== | ||

| − | An expansion vessel usually required to absorb the expansion of the water as it is heated. The volume of this will vary with the size of the cylinder. This is also normally connected to the multipurpose valve described above. The expansion vessel is pre pressurised with air (or nitrogen) contained in a bladder. There is typically a shrader valve (like that on a car tyre) fitted to the vessel to allow its pressure to be checked and if necessary replenished). | + | An expansion vessel usually required to absorb the expansion of the water as it is heated. The volume of this will vary with the size of the cylinder. This is also normally connected to the multipurpose valve described above (although other fitting locations are also allowable, see the manufacturers instructions for your particular cylinder for recommendations). |

| + | |||

| + | The expansion vessel is pre pressurised with air (or nitrogen) contained in a bladder. There is typically a shrader valve (like that on a car tyre) fitted to the vessel to allow its pressure to be checked, and if necessary replenished). | ||

| + | |||

| + | Note some unvented cylinders may have an internal pressure relief bladder or "bubble" - although these are less common now. | ||

| − | Note some unvented cylinders may have | + | (Note, that some small unvented storage cylinders of 15 litres or less, may not be required to have these, since the small amount of expansion can be accommodated by backing the water back into the mains. The only requirement is to check that all stop valves upstream are not of the 'loose jumper' type which could act as a non-return valve and block the expansion. However consult manufacturers documentation for specific details). |

===Other requirements=== | ===Other requirements=== | ||

| − | * The indirect heating coil connection must contain at least one 2-port zone valve. | + | *The indirect heating coil connection must contain at least one 2-port zone valve. |

| − | * The use of solid fuel heating is forbidden. | + | *The use of solid fuel heating is forbidden. |

| − | + | *Most manufacturers will require the fitting of an anti scaling device of some description when used in hard water areas. | |

| − | |||

| + | Note that qualification for working on these units is known informally as a "G3" card since Part 3 of the building regs approved document G used to specifically cover just the installation of unvented hot water vessels. Later versions of approved document G however now cover '''all''' hot water storage systems, not just unvented systems. | ||

==Safety of unvented systems== | ==Safety of unvented systems== | ||

| − | A properly installed and maintained system will be as safe (or in many cases safer than) | + | A properly installed and maintained system will be as safe as (or in many cases safer than) any other hot water system. |

Water expands as it is heated. Since the outlet of the cylinder is to DHW taps which are normally closed, and the inlet is from the cold water main which may incorporate non-return (check) valves or other devices preventing expansion back into the supply pipe, measures have to be provided to accommodate the expansion of the hot water which could otherwise give rise to enormous pressure in the cylinder. These take the form of some type of container of gas which can be compressed as the water expands. This may be arranged as a bubble of air in the cylinder or a separate expansion vessel. | Water expands as it is heated. Since the outlet of the cylinder is to DHW taps which are normally closed, and the inlet is from the cold water main which may incorporate non-return (check) valves or other devices preventing expansion back into the supply pipe, measures have to be provided to accommodate the expansion of the hot water which could otherwise give rise to enormous pressure in the cylinder. These take the form of some type of container of gas which can be compressed as the water expands. This may be arranged as a bubble of air in the cylinder or a separate expansion vessel. | ||

| − | At normal atmospheric pressure water boils at 100C. At higher pressures the boiling point increases so that pressurised water can be heated to over 100C and remain liquid. However if the pressure is released it will rapidly turn to steam, expanding greatly and causing a steam explosion. In the days of steam the explosion of boilers or pipework in locomotives, shipping and industry was rightly feared for the destruction and loss of life it caused. If the water in an unvented hot water cylinder is allowed to rise above 100C then the reduction of pressure when a tap is opened could cause a steam explosion. For this reason unvented systems must have safety systems to control the temperature and pressure of the water, these systems must be checked annually, and their installation and servicing must be carried out by technicians with adequate knowledge and training for these tasks. | + | At normal atmospheric pressure water boils at 100C. At higher pressures the boiling point increases so that pressurised water can be heated to over 100C and remain liquid. However if the pressure is released it will rapidly turn to steam, expanding greatly and causing a steam explosion. In the days of steam power, the explosion of boilers or steam pipework in locomotives, shipping and industry was rightly feared for the destruction and loss of life it caused. If the water in an unvented hot water cylinder is allowed to rise above 100C then the reduction of pressure when a tap is opened could cause a steam explosion. For this reason unvented systems must have safety systems to control the temperature and pressure of the water, these systems must be checked annually, and their installation and servicing must be carried out by technicians with adequate knowledge and training for these tasks. |

| − | |||

==Servicing requirements== | ==Servicing requirements== | ||

Regular service and maintenance of unvented systems is vital and should typically be carried out annually. Maintenance tasks should include: | Regular service and maintenance of unvented systems is vital and should typically be carried out annually. Maintenance tasks should include: | ||

| − | # | + | #Cleaning and inspection of the strainer in the cold water supply to the Pressure Reduction Valve |

| − | # Inspection of pressure / temperature relief valve and expansion relief valve | + | #Inspection of pressure / temperature relief valve and expansion relief valve |

| − | # Manual operation of each relief valve to ensure that water flows freely to the tundish, and that they reseat correctly. | + | #Manual operation of each relief valve to ensure that water flows freely to the tundish, and that they reseat correctly. |

| − | # | + | #Checking of the pressure in the expansion vessel, and topping up if required (see below) |

| − | == | + | === Checking and re-pressurising the expansion vessel === |

| − | + | With most cylinders, you can only test the pressure in the vessel correctly when there is no water pressure being applied to it. So to check, do the following: | |

| + | # Turn off the cold inlet valve to the system (typically feeding pipe 6 shown above) | ||

| + | # Open a hot tap, to draw off water. The water should only flow until all the water in the wet side of the expansion vessel has been expelled. Leave the hot tap open. | ||

| + | # Now check the pressure in the expansion vessel using a car tyre style pressure gauge on the Shrader valve. It should usually read around 3 bar (but check the installation instructions, or the label on the vessel for your cylinder). | ||

| + | # If the pressure is low, then add air with a suitable pump. | ||

| + | # When at the right pressure, turn off any open hot taps, and turn the main inlet valve back on. You should hear some water flow into the pressure vessel as until the pressure in the both halves balances again. | ||

| + | |||

| + | ==Manufacturers:== | ||

| + | There are many manufacturers of unvented cylinders including: Telford, Albion, Heatrae Sadia (the market leader whose model ''MegaFlo'' is used as a synonym for all other makes and models), Santon, Gledhill, Elston, IMI, & Vaillant. | ||

==See Also== | ==See Also== | ||

| − | |||

| − | |||

| − | |||

| + | :[[Special:Allpages|Wiki Contents]] | ||

| + | :[[Special:Categories|Wiki Subject Categories]] | ||

[[Category: Plumbing]] | [[Category: Plumbing]] | ||

Latest revision as of 21:20, 5 May 2021

Like a conventional hot water cylinder fed from a tank in the roof, an unvented cylinder contains hot water (heated by a boiler or immersion heater) which directly supplies the hot taps. Unlike a conventional cylinder however, the water in the unvented cylinder comes directly from the cold water main, and is at (or nearly at) mains pressure.

To contain this pressure the cylinder has to be physically much stronger than those used in gravity-fed systems. Unvented cylinders are made of thicker copper or stainless steel, and are usually more expensive than cylinders designed for vented operation.

This article describes a typical unvented cylinder installation of a size appropriate for meeting the hot water needs of a domestic property. There are some small unvented cylinders on the market (with a water capacity of 15 litres or less) designed for just providing hand wash facilities. These are in some circumstances subjected to fewer regulations and less complex system installation requirements. However they are not the primary focus of this article.

Any unvented hot water heater installation connected to the public water supply has to comply with the Water Supply (Water Fittings) Regulations 1999 and more widely, a pressurised unvented water heater also has to be installed in accordance with The Building Regulations (2016) Document G and Document H (2015)

Considerations for installation

When installed in appropriate situations, unvented cylinders are good at providing high flow rates of hot water, and can have the capacity for larger properties with multiple baths and showers. Hot water is supplied at (or near) mains pressure, and will drive showers without the need of additional pumps.

When considering an unvented cylinder, there are several factors to check first. Failure to do this could result in unsatisfactory performance, or a system not well suited to the actual requirements.

To function well, you need adequate mains pressure and an adequate flow rate (these are not the same thing). Ideally your mains pressure should be in the range of 2 - 10 bar (systems with less pressure may still work, but you will lose performance, and may find you get better results with a conventional header tank).

The mains flow rate should be a minimum of 20 Litres Per Minute (lpm) - (although more is better). The mains supply will need to meet all the household demands concurrently - hot and cold.

Advantages of Unvented cylinders

- Mains pressure hot water to all outlets

- High flow rates of hot water at "mix temperature" [1], ideal for properties with multiple showers / baths

- Fast reheat [2]

- No requirement for a header tank in the loft

- Work well in properties without adequate height available for gravity fed systems (flats, chalet style houses etc)

- Can be heated by multiple sources, e.g. gas boiler, immersion heater, solar collector.

- [1] i.e. Water that is supplied to the outlet hotter than is required so that it can be mixed with cold before use. This means the hot supply does not need to supply water at the full rate of use and hence there will have more spare capacity.

- [2] Most cylinders are equipped with large high efficiency indirect coil heat exchangers that can transfer heat at over 20kW (if the boiler is capable of supplying it). The reheat time of electric only cylinders will be dependant on the number and power of immersion heaters fitted.

Disadvantages

- More complex controls required than with a conventional vented system or combination boiler

- More expensive component costs (although total system price may be similar depending on the labour required)

- Need an adequate and reliable mains water supply (they can't supply water without a mains feed)

- Need annual servicing, possibly incurring extra cost

- Can't be heated by solid fuel stoves etc.

Selecting cylinder size

Typical unvented domestic cylinders start at around 125L and many makers do a range of sizes up to 300L or more. The smaller sizes being adequate for properties that have a single shower/bathroom. Larger sizes become more appropriate for larger properties with more baths and showers to cater for. Specifying the "right" size is not an exact science. See the Sizing a hot water cylinder article for more details.

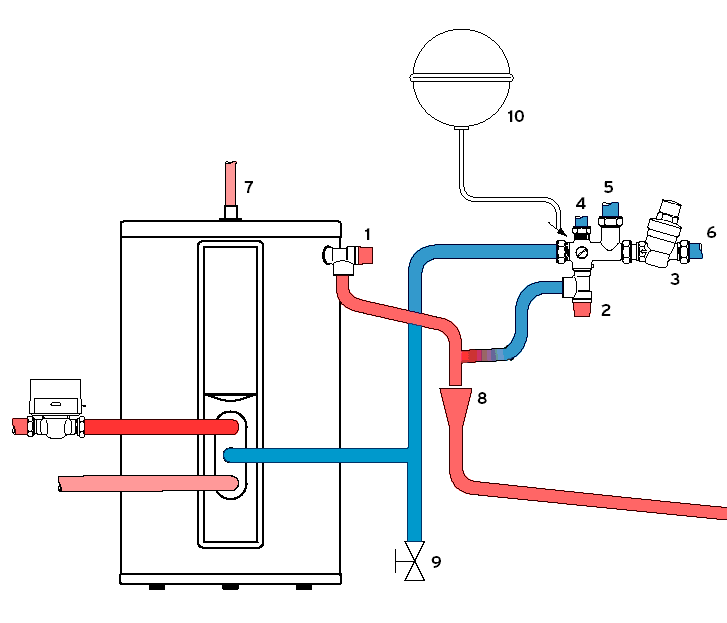

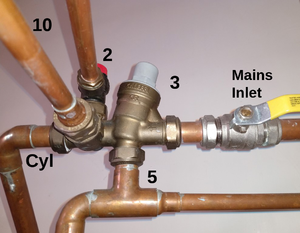

The components of an unvented cylinder

In addition to the cylinder itself, there are several other components needed to form a functional system.

- Temperature and pressure relief valve

- Expansion relief valve

- Pressure limiting valve (usually combined with a filter / strainer)

- Connection for a secondary return (often provided by an extra tapping on the cylinder)

- Balanced pressure cold water outlet

- Main cold supply inlet

- Outlet to DHW

- Tundish [1]

- Drain Point

- Expansion Vessel

Connections to the primary heating flow and return are shown to the left (with two port zone valve).

[1] A tundish (pictured above) is a device that introduces a visible air break into a pipe. In an unvented DHW system it serves two purposes; Firstly it adds to the protection of incoming public water main, reducing further the possibility of contamination from your hot water system, secondly, it gives a visible indication of any water being released from any of the safety valves fitted to the system.

Valves

- A check valve (which is usually implemented as part of the pressure reduction valve).

- A pressure reduction valve typically set to around 3 bar (although other pressures are sometimes used).

There may also be a cold water outlet point after the pressure reducing valve to supply e.g. shower mixing valves which work better when their hot and cold supplies are at the same pressure.

- A pressure relief valve (typically set to 6 bar), this is mounted on the inlet to the cylinder.

The above items are often found combined into a single multifunction unit.

- A combined over pressure and temperature relief valve. This is always on the side of the cylinder. It will typically be set to 7 bar and 90C. The thread that is used for this fitting is unique to this type of device to avoid the hole being used for any other purpose and so that the only way to block the hole is to install the valve.

(The reason for the temperature limiting valve in addition to a pressure limiting one is so that if a heating source fails to cut out, it is possible for the pressure rise will remain quite modest until the water reaches well over 100C (even 1 bar will raise the boiling point to around 120C). So neither pressure relief valve would open and yet the contents of the cylinder would be lethal and will 'flash' boil to steam when pressure in the system is reduced by opening a tap. Should this valve operate, it will dump some of the contents of the cylinder (containing water at 90C!) into the relief discharge pipework. The valve will only close when cooler water from the mains supply has reached it. This is also why there are stringent requirements for the size, length and routing of the discharge pipe.

Thermal Cutouts

The thermostats for the immersion heater(s) (if fitted) need to be of a type that includes a second higher temperature cut-out requiring manual resetting if it operates.

The connection to a boiler (if provided) must be via a zone valve connected controlled by both a normal cylinder thermostat (or equivalent electronic sensor). It should also be connected via also a second high temperature cutout.

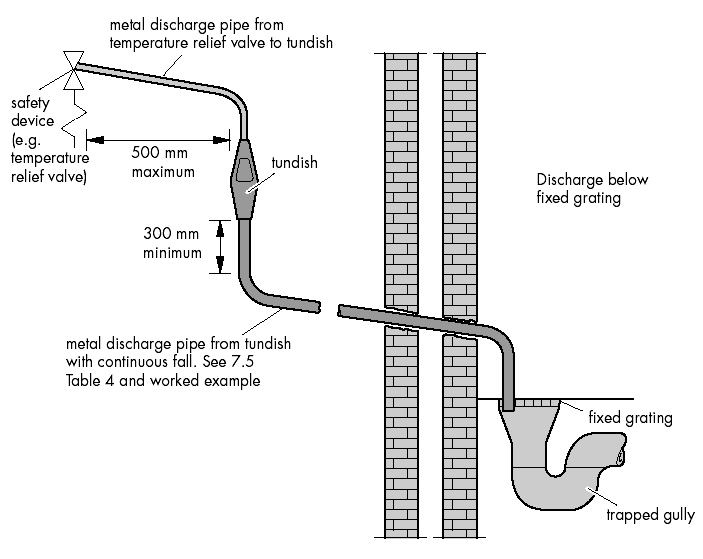

Discharge Pipe

The pressure relief and over temperature valves discharge into an emergency relief discharge pipe complying with Water Regulations Section 8 Schedule 2 G19 Discharge pipes from safety devices; G19.1; G19.3; & G19.4. They are usually combined and connected to a tundish complying with WRAS test code sheet number 221210, which in turn feeds the discharge pipe. The tundish provides an air gap required between anything connected directly to a mains water supply, and a drain so as to prevent any possibility of back contamination of the mains supply to comply with Water Regulations section 6.3 – Regulator’s specification for backflow prevention arrangements and devices for the requirement for fittings – and section 6.4 Guidance clauses related to schedule 1 : Fluid categories; and Paragraph 15 of Schedule 2: Backflow prevention. It also provides a visible indication of any loss of water via the safety valves. The discharge pipe must be metallic (or certified as capable of handling a significant flow of near boiling water) and of at least 22mm diameter.

The maximum effective length of pipe from the tundish is also specified:

| Minimum size of discharge

pipe pipework from tundish |

Maximum effective

length |

Effective length of

each elbow or bend |

|---|---|---|

| 22mm | 9m | 0.8m |

| 27mm | 18m | 1.0m |

| 35mm | 27m | 1.4m |

There must be a vertical drop of pipe after the tundish (minimum length of 300mm) before any bends. The discharge pipe must terminate outside of the building in a safe place such as a gully where it can't cause injury (Building Regulations G3 (3)(b)) (other discharge positions may be acceptable so long as measures are taken to minimise risk of injury to bystanders). In blocks of flats and similar, an internal discharge to the soil waste may be used providing precautions are taken against back-contamination (Building regulations H1 Guidance: c). The Hotun dry trap tundish may be used in such circumstances.

Expansion vessel

An expansion vessel usually required to absorb the expansion of the water as it is heated. The volume of this will vary with the size of the cylinder. This is also normally connected to the multipurpose valve described above (although other fitting locations are also allowable, see the manufacturers instructions for your particular cylinder for recommendations).

The expansion vessel is pre pressurised with air (or nitrogen) contained in a bladder. There is typically a shrader valve (like that on a car tyre) fitted to the vessel to allow its pressure to be checked, and if necessary replenished).

Note some unvented cylinders may have an internal pressure relief bladder or "bubble" - although these are less common now.

(Note, that some small unvented storage cylinders of 15 litres or less, may not be required to have these, since the small amount of expansion can be accommodated by backing the water back into the mains. The only requirement is to check that all stop valves upstream are not of the 'loose jumper' type which could act as a non-return valve and block the expansion. However consult manufacturers documentation for specific details).

Other requirements

- The indirect heating coil connection must contain at least one 2-port zone valve.

- The use of solid fuel heating is forbidden.

- Most manufacturers will require the fitting of an anti scaling device of some description when used in hard water areas.

Note that qualification for working on these units is known informally as a "G3" card since Part 3 of the building regs approved document G used to specifically cover just the installation of unvented hot water vessels. Later versions of approved document G however now cover all hot water storage systems, not just unvented systems.

Safety of unvented systems

A properly installed and maintained system will be as safe as (or in many cases safer than) any other hot water system.

Water expands as it is heated. Since the outlet of the cylinder is to DHW taps which are normally closed, and the inlet is from the cold water main which may incorporate non-return (check) valves or other devices preventing expansion back into the supply pipe, measures have to be provided to accommodate the expansion of the hot water which could otherwise give rise to enormous pressure in the cylinder. These take the form of some type of container of gas which can be compressed as the water expands. This may be arranged as a bubble of air in the cylinder or a separate expansion vessel.

At normal atmospheric pressure water boils at 100C. At higher pressures the boiling point increases so that pressurised water can be heated to over 100C and remain liquid. However if the pressure is released it will rapidly turn to steam, expanding greatly and causing a steam explosion. In the days of steam power, the explosion of boilers or steam pipework in locomotives, shipping and industry was rightly feared for the destruction and loss of life it caused. If the water in an unvented hot water cylinder is allowed to rise above 100C then the reduction of pressure when a tap is opened could cause a steam explosion. For this reason unvented systems must have safety systems to control the temperature and pressure of the water, these systems must be checked annually, and their installation and servicing must be carried out by technicians with adequate knowledge and training for these tasks.

Servicing requirements

Regular service and maintenance of unvented systems is vital and should typically be carried out annually. Maintenance tasks should include:

- Cleaning and inspection of the strainer in the cold water supply to the Pressure Reduction Valve

- Inspection of pressure / temperature relief valve and expansion relief valve

- Manual operation of each relief valve to ensure that water flows freely to the tundish, and that they reseat correctly.

- Checking of the pressure in the expansion vessel, and topping up if required (see below)

Checking and re-pressurising the expansion vessel

With most cylinders, you can only test the pressure in the vessel correctly when there is no water pressure being applied to it. So to check, do the following:

- Turn off the cold inlet valve to the system (typically feeding pipe 6 shown above)

- Open a hot tap, to draw off water. The water should only flow until all the water in the wet side of the expansion vessel has been expelled. Leave the hot tap open.

- Now check the pressure in the expansion vessel using a car tyre style pressure gauge on the Shrader valve. It should usually read around 3 bar (but check the installation instructions, or the label on the vessel for your cylinder).

- If the pressure is low, then add air with a suitable pump.

- When at the right pressure, turn off any open hot taps, and turn the main inlet valve back on. You should hear some water flow into the pressure vessel as until the pressure in the both halves balances again.

Manufacturers:

There are many manufacturers of unvented cylinders including: Telford, Albion, Heatrae Sadia (the market leader whose model MegaFlo is used as a synonym for all other makes and models), Santon, Gledhill, Elston, IMI, & Vaillant.