Difference between revisions of "Wallplug"

(Incomplete article) |

|||

| (26 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

| − | + | [[image:Wallplugs selection 0175-4.jpg|400px]] | |

| − | |||

| − | |||

| − | [[image:Wallplugs | ||

| − | |||

==Plugs for solid masonry== | ==Plugs for solid masonry== | ||

===Standard plug=== | ===Standard plug=== | ||

| − | [[image: | + | [[image:Classic wallplug 0175-7.jpg|right|150px]] |

The standard moulded polythene wallplug is by far the most popular option. These come with recommended hole and [[Screws|screw]] sizes, and are simple to use. | The standard moulded polythene wallplug is by far the most popular option. These come with recommended hole and [[Screws|screw]] sizes, and are simple to use. | ||

| + | * Different sizes are usually colour coded, but different brands don't all follow the same colour code. | ||

| + | * These come in various styles/shapes, but all do the same job. | ||

| + | * Nylon plugs cost more and are tougher | ||

| − | |||

===Fibre plugs=== | ===Fibre plugs=== | ||

| − | [[image:Fibre wallplug | + | [[image:Fibre wallplug 0175-6.jpg|right|150px]] |

| − | Fibre plugs are straight sided compacted fibre plugs. | + | Fibre plugs are straight sided compacted cellulose fibre plugs. |

| + | * They're hard to find today. | ||

===Lipless plug=== | ===Lipless plug=== | ||

| − | [[image:Lipless wallplug | + | [[image:Lipless wallplug 0175-5.jpg|right|150px]] |

| − | Plugs with no lip are good when using 2 moulded plugs in a hole. Also used in tiles. | + | * Plugs with no lip are good when using 2 moulded plugs in a hole. |

| + | * Also used in tiles. | ||

===Sticks=== | ===Sticks=== | ||

| − | [[image:Wallplug stick | + | [[image:Wallplug stick 5046-2.jpg|right|150px]] |

| − | Long sticks are no longer common, but are still available. | + | * Long sticks are no longer common, but are still available. |

| + | * Allows you to cut a plug of any length. | ||

| + | * They come in plastic or fibre, about a foot long. | ||

===Sheet metal plugs=== | ===Sheet metal plugs=== | ||

| − | These are made from contorted thin sheet metal | + | These are made from contorted thin sheet metal |

| + | * Fire resistant. | ||

| + | * In soft masonry they have a lower pullout rating than a plastic plug, due to distributing the force on the masonry less evenly. | ||

===Metal anchor=== | ===Metal anchor=== | ||

| − | These use 2 cast halves of metal than expand when a bolt is [[Screws|screwed]] in. Not suited to use with regular wood [[screws]]. These put high forces on the masonry, so should not be used near edges. | + | These use 2 cast halves of metal than expand apart when a bolt is [[Screws|screwed]] in. |

| + | * Not suited to use with regular wood [[screws]]. | ||

| + | * These put high forces on the masonry, so should not be used near edges. | ||

==Plugs for hollow walls== | ==Plugs for hollow walls== | ||

===Expanding plastic plug=== | ===Expanding plastic plug=== | ||

| − | The cheapest type of hollow wall plug, these look similar to regular plastic plugs, but | + | The cheapest type of hollow wall plug, these look quite similar to regular plastic plugs, but the plug expands behind the [[Sheet Materials|plasterboard]] when [[Screws|screwed]] into, rather than along its whole length. |

===Universal plug=== | ===Universal plug=== | ||

| − | These are expanding plastic plugs that can be used with both solid and [[Partition Wall|hollow walls]] | + | These are expanding plastic plugs that can be used with both solid and [[Partition Wall|hollow walls]] |

===Redidrive=== | ===Redidrive=== | ||

| − | [[image: | + | [[image:Redidrive wallplug 0176-8.jpg|thumb|Redidrive]] |

| − | Available in metal and plastic | + | * Available in metal and plastic |

| + | * These [[Screws|screw]] into the [[Sheet Materials|plasterboard]] | ||

| + | * Aka Easidriver | ||

===Hammer in=== | ===Hammer in=== | ||

| − | [[image:Hammer in | + | [[image:Hammer in wallplugs 0176-7.jpg|thumb|Hammer in]] |

| − | 2 sheet metal legs spread when [[Screws|screw]] inserted | + | * 2 sheet metal legs spread when [[Screws|screw]] inserted |

| + | * No hole is drilled, they're just [[Hammers|hammered]] into position | ||

| + | * Fast to use | ||

| + | * Load rating so-so | ||

===Spring & gravity toggle=== | ===Spring & gravity toggle=== | ||

| − | [[image:Toggle wallplugs | + | [[image:Toggle wallplugs 0177-6.jpg|thumb|Toggle plugs]] |

| − | + | * Toggles use a metal bar behind the [[Sheet Materials|plasterboard]] to take the load. | |

| + | * Fairly good load rating for static loads | ||

| + | * With dynamic loads, such as coathooks, both toggle types tend to gradually eat through the plasterboard until it eventually fails | ||

| − | ===Lightweight | + | ===Lightweight hollow wall plugs=== |

| − | [[image: | + | [[image:lightweight hollow wall plugs 0176-6.jpg|thumb|Lightweight]] |

| + | * Minimum cost hollow wall plugs | ||

| + | * Small area of grip | ||

| + | * Low load levels only | ||

===Hollow wall anchor=== | ===Hollow wall anchor=== | ||

| − | [[image: | + | [[image:wall anchor metal 0178-6.jpg|thumb|Hollow wall anchor]] |

| + | A bolt type fixing for hollow walls. | ||

==Better than hollow wall plugs== | ==Better than hollow wall plugs== | ||

| − | Hollow wall plug fixings are only ever as strong as the [[Sheet Materials|plasterboard]]. Where greater strength is necessary: | + | Hollow wall plug fixings are only ever as strong as the [[Sheet Materials|plasterboard]]. Where greater strength is necessary, fix to anything but the plasterboard: |

| − | * fix through to solid masonry behind the plasterboard, if there is any | + | * fix through to solid masonry behind the plasterboard, if there is any (don't overtighten the screw) |

* fix to an upright or nogging on [[Partition Wall|frame walls]] | * fix to an upright or nogging on [[Partition Wall|frame walls]] | ||

* Replace the [[Sheet Materials|plasterboard]] with [[Sheet Materials#Plywood|plywood]], or fit ply to the surface | * Replace the [[Sheet Materials|plasterboard]] with [[Sheet Materials#Plywood|plywood]], or fit ply to the surface | ||

| Line 69: | Line 86: | ||

| − | == | + | ==Names== |

| − | + | All these fixings that take a separate screw are called wall plugs. The expanding ones with a captive bolt are anchors. | |

| − | |||

| + | Rawlplug is a famous brand of wallplug, and the name is often used regardless of brand. | ||

==Methods== | ==Methods== | ||

| Line 83: | Line 100: | ||

===Reduced hole size=== | ===Reduced hole size=== | ||

| − | Soft masonry tends to produce a | + | Soft masonry tends to produce a hole bigger than the drill bit. A drill bit half a mm smaller helps keep things tight. |

===2 plugs=== | ===2 plugs=== | ||

| Line 89: | Line 106: | ||

===Packing=== | ===Packing=== | ||

| − | Uneven or oversize holes will need packing to make them work. | + | Uneven or oversize holes will need packing or filling to make them work. Packing can be done with matchsticks or split wallplugs. These are hammered in, and if the screw doesn't grip tight when it goes in then the hole is packed again. |

| + | ===Filling=== | ||

| + | Any ordinary filler works fine, no need to use anything especially tough. Filler is needed if the hole disintegrates, which sometimes happens. Using filler is slow of course. | ||

| + | |||

| + | No more nails type adhesives aren't suitable as fillers, they're too soft for this task. | ||

==Troubles== | ==Troubles== | ||

| Line 98: | Line 119: | ||

* Blow dust out and reinsert plug | * Blow dust out and reinsert plug | ||

* Use a bigger plug that fits tighter | * Use a bigger plug that fits tighter | ||

| − | * Fill hole with filler, and when set re-drill | + | * Fill hole with [[filler]], and when set re-drill |

* Pack something round the plug before reinserting | * Pack something round the plug before reinserting | ||

| − | * [[Hammers|Hammer]] matchsticks into all available gaps. Matchsticks leave a lot of gaps so you need to pack every | + | * [[Hammers|Hammer]] matchsticks into all available gaps. Matchsticks leave a lot of gaps so you need to pack every available gap. Insert [[Screws|screw]], remove it again and hammer more matchsticks in. Now you'll get a good strong bite. |

* Insert [[Adhesive|resin glue]] into hole, refit plug, let set. | * Insert [[Adhesive|resin glue]] into hole, refit plug, let set. | ||

* Other bulking glues can also be used, such as polyurethane. They aren't as strong. | * Other bulking glues can also be used, such as polyurethane. They aren't as strong. | ||

* Put a quick set filler disc around the plug, reinsert the plug, let it set. | * Put a quick set filler disc around the plug, reinsert the plug, let it set. | ||

| − | |||

===Hole oversize or misshapen=== | ===Hole oversize or misshapen=== | ||

Either: | Either: | ||

* Drill deeper and use 2 plugs to get a deep fixing. | * Drill deeper and use 2 plugs to get a deep fixing. | ||

| − | * Blow all debris out of hole, fill with interior filler, try again tomorrow. | + | * Blow all debris out of hole, fill with interior [[filler]], try again tomorrow. |

* Use resin, with or without plug | * Use resin, with or without plug | ||

* Use a filler disc around the plug | * Use a filler disc around the plug | ||

| Line 117: | Line 137: | ||

===Some holes crumble=== | ===Some holes crumble=== | ||

| − | If some do some don't, | + | If some do some don't, coat all holes inside and out with glue (eg [[Adhesive|pva]]) and fix when the glue is set. The pva reinforces the crumbly material. If the PVA is diluted it soaks in better, but it works diluted or not. |

===Plug & screw pulls out=== | ===Plug & screw pulls out=== | ||

| − | If the whole fixing pulls out after the [[Screws|screw]] is in, then the plug & screw are too small for the hole. | + | If the whole fixing pulls out after the [[Screws|screw]] is in, then usually the plug & screw are too small for the hole. |

* Pack the plug | * Pack the plug | ||

* Use a much thicker screw | * Use a much thicker screw | ||

| Line 126: | Line 146: | ||

* fill the hole and retry once set | * fill the hole and retry once set | ||

* Use resin | * Use resin | ||

| + | |||

| + | The other possiblity is the masonry is very weak and has disintegrated. Glue or [[filler]] can solve this. | ||

===Screw jams=== | ===Screw jams=== | ||

[[Screws|Screw]] too thick for plug & hole. Use a thinner screw, or possibly a thinner plug or slightly increased hole size. | [[Screws|Screw]] too thick for plug & hole. Use a thinner screw, or possibly a thinner plug or slightly increased hole size. | ||

| + | |||

| + | If things turn out to be so far off that you don't have a screw thin enough to go in ok, the centre of the plug can be drilled, but don't drill it as big as the screw shank. | ||

===Hollow wall plug pulled out=== | ===Hollow wall plug pulled out=== | ||

| Line 141: | Line 165: | ||

==When plugs don't work== | ==When plugs don't work== | ||

| − | There are a couple of wall materials where plugs won't work no matter what. | + | There are a couple of wall materials where plugs won't work no matter what you do. The main types are earth & straw walls. With these walls another fixing method altogether is needed, normally one where the load is supported by the floor instead of the wall. |

| + | |||

| + | In some cases using a timber frame fixed to floor and ceiling is about the only safe option. This is true for example of a large screen TV mounted to an earth wall. | ||

| − | + | For lesser loads one can attach sheet ply to the wall, using plenty of fixings, and attach the load to that. | |

==Plug Material== | ==Plug Material== | ||

| − | Plastic is most popular and the cheapest. Plastics are vulnerable to heat, and in a fire | + | Plastic is most popular and the cheapest. |

| + | * Plastics are vulnerable to heat, and in a [[fire]] plastic plugged fixings are liable to collapse. Bear that in mind when fixing items along an escape route | ||

| + | * Plastics aren't affected by [[water]], making them good for outdoor use. | ||

| + | * Nylon plugs are tougher than lower cost polythene, and support a greater load. | ||

| − | + | Metal plugs | |

| + | * much better fire resistance | ||

| + | * vulnerable to rust outdoors | ||

| + | * weaker fixing than plastic in soft [[masonry]] | ||

| + | * stronger fixing than plastic in high strength masonry. | ||

| − | + | Wood plugs | |

| + | * better fire resistance than plastic. | ||

| + | * vulnerable to [[Wood Rot|rot]] outdoors, best avoided | ||

| − | + | Fibre plugs are tougher than plastic. | |

| − | |||

| + | ==Wallplug substitutes== | ||

| + | If no wallplugs are to hand, there are substitutes that can be used. | ||

| − | |||

| − | |||

===Commercial=== | ===Commercial=== | ||

Dowel | Dowel | ||

===Ad hoc=== | ===Ad hoc=== | ||

| − | + | When you've got nothing else to hand... | |

| − | + | * Matchsticks - [[Hammers|hammer]] in & snap off. Pack them tight, [[Screws|screw]] in, remove screw and repack. | |

| − | Matchsticks - [[Hammers|hammer]] in & snap off. Pack them tight, [[Screws|screw]] in, remove screw and repack. | + | * Bit of wood split off. [[Hammers|Hammer]] more slivers of wood into any gaps. Like matchsticks, a second packing is generally needed. |

| − | + | * Rolled paper - not a great performer but can work. | |

| − | Rolled paper - not a great performer but can work. | + | * Card - folded card works if packed well enough. |

| − | + | * Bits of plastic - another poor performer but can work if packed tight enough, ie they need to be [[Hammers|hammered]] in. | |

| − | Card - folded card works if packed well enough. | + | * Once I tried thin offcut strips of ceramic tile as a plug in a concrete wall, and was most surprised when they worked perfectly. |

| − | |||

| − | Bits of plastic - another poor performer but can work if packed tight enough, ie they need to be [[Hammers|hammered]] in. | ||

| − | |||

| − | |||

| Line 184: | Line 214: | ||

* Plastic aerated concrete nail - hammers into aerated blocks | * Plastic aerated concrete nail - hammers into aerated blocks | ||

* [[Adhesive|Resin]] fixing - higher load rating than any plug type - fill hole with resin, let set, drill & screw | * [[Adhesive|Resin]] fixing - higher load rating than any plug type - fill hole with resin, let set, drill & screw | ||

| − | * Wedge - remove some mortar from between bricks, | + | * Wedge - remove some mortar from between bricks, [[Hammers|hammer]] in wooden wedge) |

| − | |||

* In extremis, fix to floor or ceiling instead. | * In extremis, fix to floor or ceiling instead. | ||

| − | * Putties - various | + | * [[Putty|Putties]] - various [[filler]]s, [[glue]]s & putties can be used to fill a hole and [[screw]] into. Historic brands include Rawlplastic & Philplug. Good for uneven shaped holes. |

| − | |||

==See Also== | ==See Also== | ||

| + | * There are more types of wallplug you can see at for example [http://www.screwfix.com/cats/5/Fixings;jsessionid=LMBHR15SQ1EL4CSTHZOSFEY here] | ||

* [[Screws]] | * [[Screws]] | ||

* [[Adhesive]] | * [[Adhesive]] | ||

* [[Fixing to Plasterboard Walls]] | * [[Fixing to Plasterboard Walls]] | ||

| + | * [https://www.youtube.com/watch?v=mIEY3E4fiDk Plasterboard wall plugs, the good the bad & the useless] 10mins | ||

* [http://www.screwfix.com/search.do;jsessionid=NIRSN2IZCBZMUCSTHZOSFFQ?_dyncharset=UTF-8&fh_search=Fischer+Wet&x=0&y=0 Fischer filler discs] | * [http://www.screwfix.com/search.do;jsessionid=NIRSN2IZCBZMUCSTHZOSFFQ?_dyncharset=UTF-8&fh_search=Fischer+Wet&x=0&y=0 Fischer filler discs] | ||

* [[Special:Allpages|Wiki Contents]] | * [[Special:Allpages|Wiki Contents]] | ||

| Line 203: | Line 233: | ||

[[Category:Fixings]] | [[Category:Fixings]] | ||

[[Category:Basics]] | [[Category:Basics]] | ||

| + | [[Category:Masonry]] | ||

| + | [[Category:Shelving]] | ||

Latest revision as of 12:19, 7 December 2016

Plugs for solid masonry

Standard plug

The standard moulded polythene wallplug is by far the most popular option. These come with recommended hole and screw sizes, and are simple to use.

- Different sizes are usually colour coded, but different brands don't all follow the same colour code.

- These come in various styles/shapes, but all do the same job.

- Nylon plugs cost more and are tougher

Fibre plugs

Fibre plugs are straight sided compacted cellulose fibre plugs.

- They're hard to find today.

Lipless plug

- Plugs with no lip are good when using 2 moulded plugs in a hole.

- Also used in tiles.

Sticks

- Long sticks are no longer common, but are still available.

- Allows you to cut a plug of any length.

- They come in plastic or fibre, about a foot long.

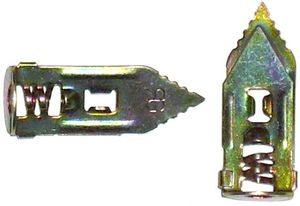

Sheet metal plugs

These are made from contorted thin sheet metal

- Fire resistant.

- In soft masonry they have a lower pullout rating than a plastic plug, due to distributing the force on the masonry less evenly.

Metal anchor

These use 2 cast halves of metal than expand apart when a bolt is screwed in.

- Not suited to use with regular wood screws.

- These put high forces on the masonry, so should not be used near edges.

Plugs for hollow walls

Expanding plastic plug

The cheapest type of hollow wall plug, these look quite similar to regular plastic plugs, but the plug expands behind the plasterboard when screwed into, rather than along its whole length.

Universal plug

These are expanding plastic plugs that can be used with both solid and hollow walls

Redidrive

- Available in metal and plastic

- These screw into the plasterboard

- Aka Easidriver

Hammer in

- 2 sheet metal legs spread when screw inserted

- No hole is drilled, they're just hammered into position

- Fast to use

- Load rating so-so

Spring & gravity toggle

- Toggles use a metal bar behind the plasterboard to take the load.

- Fairly good load rating for static loads

- With dynamic loads, such as coathooks, both toggle types tend to gradually eat through the plasterboard until it eventually fails

Lightweight hollow wall plugs

- Minimum cost hollow wall plugs

- Small area of grip

- Low load levels only

Hollow wall anchor

A bolt type fixing for hollow walls.

Better than hollow wall plugs

Hollow wall plug fixings are only ever as strong as the plasterboard. Where greater strength is necessary, fix to anything but the plasterboard:

- fix through to solid masonry behind the plasterboard, if there is any (don't overtighten the screw)

- fix to an upright or nogging on frame walls

- Replace the plasterboard with plywood, or fit ply to the surface

- Fix to floor instead

Names

All these fixings that take a separate screw are called wall plugs. The expanding ones with a captive bolt are anchors.

Rawlplug is a famous brand of wallplug, and the name is often used regardless of brand.

Methods

The standard method is to drill the hole size recommended, blow dust from the hole, insert the plug full depth, and use a screw of the thickness recommended. Of course this isn't the only option.

Other screw sizes

Where grip is likely to be poor, a thicker than recommended screw can increase compression on the plug and thus grip.

A thinner than recommneded screw can be used to ease driving where the recommended size is too tight.

Reduced hole size

Soft masonry tends to produce a hole bigger than the drill bit. A drill bit half a mm smaller helps keep things tight.

2 plugs

For a stronger fixing, a deep hole & 2 plugs are used. This is especially useful in soft masonry, and where the surface layer is weak, eg crumbly plaster.

Packing

Uneven or oversize holes will need packing or filling to make them work. Packing can be done with matchsticks or split wallplugs. These are hammered in, and if the screw doesn't grip tight when it goes in then the hole is packed again.

Filling

Any ordinary filler works fine, no need to use anything especially tough. Filler is needed if the hole disintegrates, which sometimes happens. Using filler is slow of course.

No more nails type adhesives aren't suitable as fillers, they're too soft for this task.

Troubles

It just keeps turning

If a wallplug just turns instead of tightening, the following sometimes work:

- Blow dust out and reinsert plug

- Use a bigger plug that fits tighter

- Fill hole with filler, and when set re-drill

- Pack something round the plug before reinserting

- Hammer matchsticks into all available gaps. Matchsticks leave a lot of gaps so you need to pack every available gap. Insert screw, remove it again and hammer more matchsticks in. Now you'll get a good strong bite.

- Insert resin glue into hole, refit plug, let set.

- Other bulking glues can also be used, such as polyurethane. They aren't as strong.

- Put a quick set filler disc around the plug, reinsert the plug, let it set.

Hole oversize or misshapen

Either:

- Drill deeper and use 2 plugs to get a deep fixing.

- Blow all debris out of hole, fill with interior filler, try again tomorrow.

- Use resin, with or without plug

- Use a filler disc around the plug

Hole keeps crumbling

Blow all debris out of hole, fill with interior filler, try again tomorrow.

Some holes crumble

If some do some don't, coat all holes inside and out with glue (eg pva) and fix when the glue is set. The pva reinforces the crumbly material. If the PVA is diluted it soaks in better, but it works diluted or not.

Plug & screw pulls out

If the whole fixing pulls out after the screw is in, then usually the plug & screw are too small for the hole.

- Pack the plug

- Use a much thicker screw

- Use a thicker plug if it'll fit

- fill the hole and retry once set

- Use resin

The other possiblity is the masonry is very weak and has disintegrated. Glue or filler can solve this.

Screw jams

Screw too thick for plug & hole. Use a thinner screw, or possibly a thinner plug or slightly increased hole size.

If things turn out to be so far off that you don't have a screw thin enough to go in ok, the centre of the plug can be drilled, but don't drill it as big as the screw shank.

Hollow wall plug pulled out

That's life, plasterboard isn't very strong. Some hollow plugs grip more area of plasterboard than others, but if these aren't tough enough you'll need to fix to something stronger than plasterboard. That could be

- solid masonry behind a gap behind the plasterboard

- wood or metal frame

- sheet ply on the wall

- fix to the floor

- in extremis build a wood frame fixed to floor & ceiling, and fix to that.

- or use a free standing appliance instead

When plugs don't work

There are a couple of wall materials where plugs won't work no matter what you do. The main types are earth & straw walls. With these walls another fixing method altogether is needed, normally one where the load is supported by the floor instead of the wall.

In some cases using a timber frame fixed to floor and ceiling is about the only safe option. This is true for example of a large screen TV mounted to an earth wall.

For lesser loads one can attach sheet ply to the wall, using plenty of fixings, and attach the load to that.

Plug Material

Plastic is most popular and the cheapest.

- Plastics are vulnerable to heat, and in a fire plastic plugged fixings are liable to collapse. Bear that in mind when fixing items along an escape route

- Plastics aren't affected by water, making them good for outdoor use.

- Nylon plugs are tougher than lower cost polythene, and support a greater load.

Metal plugs

- much better fire resistance

- vulnerable to rust outdoors

- weaker fixing than plastic in soft masonry

- stronger fixing than plastic in high strength masonry.

Wood plugs

- better fire resistance than plastic.

- vulnerable to rot outdoors, best avoided

Fibre plugs are tougher than plastic.

Wallplug substitutes

If no wallplugs are to hand, there are substitutes that can be used.

Commercial

Dowel

Ad hoc

When you've got nothing else to hand...

- Matchsticks - hammer in & snap off. Pack them tight, screw in, remove screw and repack.

- Bit of wood split off. Hammer more slivers of wood into any gaps. Like matchsticks, a second packing is generally needed.

- Rolled paper - not a great performer but can work.

- Card - folded card works if packed well enough.

- Bits of plastic - another poor performer but can work if packed tight enough, ie they need to be hammered in.

- Once I tried thin offcut strips of ceramic tile as a plug in a concrete wall, and was most surprised when they worked perfectly.

Alternatives

- Hammer fixings - hammer-in screw & plug in one.

- Frame fixings - long hammer fixings

- Masonry screw - eg multi monte - screw direct into masonry, no plug

- Masonry nail

- Plastic aerated concrete nail - hammers into aerated blocks

- Resin fixing - higher load rating than any plug type - fill hole with resin, let set, drill & screw

- Wedge - remove some mortar from between bricks, hammer in wooden wedge)

- In extremis, fix to floor or ceiling instead.

- Putties - various fillers, glues & putties can be used to fill a hole and screw into. Historic brands include Rawlplastic & Philplug. Good for uneven shaped holes.

See Also

- There are more types of wallplug you can see at for example here

- Screws

- Adhesive

- Fixing to Plasterboard Walls

- Plasterboard wall plugs, the good the bad & the useless 10mins

- Fischer filler discs

- Wiki Contents

- Wiki Subject Categories