Putty & Mastic

Putties & Mastics are materials used for gap filling, waterproofing & sealing and glazing.

Types

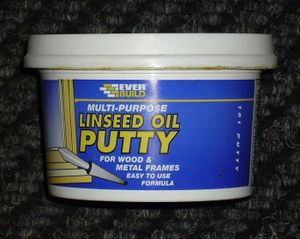

Linseed putty

Linseed putty is the traditional putty for window glazing.

- Make from linseed oil & whiting (chalk)

- Very slow setting.

- Easy to work, smooth with a wet or linseed oiled knife blade.

- Best not to overpaint until set.

- Do not leave unpainted too long or it will deteriorate.

- Using boiled oil makes putty set faster than raw oil.

- When buying, check the putty is still soft, partly hardened putty is sold too often. Just squeeze the tub.

- Old half hard putty may be made usable by adding a little linseed oil and mixing.

- Stiff putty can also be made workable by adding a tiny amount of water and working in well. Although this is on the face of it the wrong solvent, it still works well.

When painting linseed putty it is important to overlap the edge of the putty very slightly with paint. Failing to do this results in premature putty failure and water ingress, which may cause wood rot.

Old putty is hard and tough. It may be removed with a knife, though the going is usually slow. When it proves difficult, heating the putty softens it to some degree. A radiant IR heater heats the putty more than the glass, whereas heat guns heat both.

Alkyd putty

Alkyd putty is a linseed putty replacement

- Faster drying than linseed putty.

- Can be made by mixing household gloss paint & whiting (chalk powder)

Silicone sealant

Silicone has many uses, and there are a number of different types of product to choose from. For more detail & information see the Silicone Sealant article.

Main Properties

- Remains permanently elastic after curing.

- Long life expectancy in many applications.

- Does not shrink.

- Water based formula.

- Keeps its colour and is waterproof.

- Resists most chemicals and solvents.

- Is non toxic after curing.

- Has very good adhesion to glass and all commonly used building materials.

- Resists temperatures ranging from -60°C to +200°C

- Supports mould growth

Uses

- Sealing gaps round baths, showers, windows, worktops

- Fixing mirrors or glass to tiled surfaces

- Sealing gutters and downpipes

- Repairing rubber trim on cars

- Moulding into soft rubber goods of most shapes

- Making reusable flexible moulds

Burnt sand mastic

- Made from very dry silver sand & linseed oil. May contain driers for a quicker set.

- Coarser than linseed putty.

- Also known as Scotch Mastic.

- When made without driers, setting will be very slow and the mix should be stiff.

- Bonds well to brick, stone and timber.

- Burnt sand mastic was traditionally used around door & window frames, but is not in general use today.

- Looks much better with masonry than modern mastics.

- More elastic than cement mortar. Forms a tough skin with a flexible core.

- Very long lived, very slow setting.

- Some birds like to eat it while wet. Overpainting prevents this.

- How to use

Butyl putty

- Does not set like linseed

Acrylic

- Low cost sealant.

- Less durable and shorter lived than silicones.

Polyurethane

- Suitable for continuous immersion, used in marine applications.

- eg Sikaflex

Marine Sealants

Sealants for marine use need to be tougher and generally cost more.

Sealants often recommended in uk.rec.sailing include:

Adflex

- Black, white & brown

- From builder's merchants

Arc-Loyal

- MS polymer

- Slow curing

- Good for underwater use

Evostick Nail and Seal

- MS polymer

- Low cost, £3.99 from B&Q

- May be confused with similar named products with different formulae

Polysulphide

- Low cost

- B&Q used for

- Good for underwater use

Sikaflex

- wide range of colours

Storage

Before Opening

Some sealants, especially silicone, have limited shelf life. When unfit they may either be hardened in the tube, or else appear normal but fail to ever cure.

If your tube is past its best before date, a blob can be tested to see if it sets OK before doing the job.

After Opening

No method guarantees successful storage once the tube is opened, but the following work a lot of the time:

- Remove & clear nozzle, apply cling film or polythene sheet over the tube and refit nozzle.

- Wrap polythene round the nozzle, secure with a wire tie.

- Crumple ali foil over the nozzle, squeeze a little product into the foil and let set.

- Put a screw or nail into the nozzle end.

Once Set

Finally, if material in the tube has hardened, sometimes fresh unset gloop can be reached by drilling a hole into the hard set mass. This is likely to free lumps that repeatedly clog the nozzle, so is not a good option, but can occasionally be of use.