Bracket

This describes both ready made and DIY brackets.

Making brackets is useful when:

- Something special is wanted

- Quick basic brackets are wanted

- Sufficient quantity of brackets are wanted to make a worthwhile saving

- Decorative brackets are wanted

Selection Table

Type Cost Load DIYable ---- ---- ---- ------- Metal ----- London M Med no Hi-load £2 Hi no Microwave £10 Hi no TV £10-20 V Hi no Mitred £2 Hi no Gallows £1 Med no Corner Brace 10p V lo yes Braced strip ~ 0 V lo yes Shrinkage Triangular ~ 0 Med yes Floating Lo-Med no Splash ~ £3 Low no Bookcase Support Med no Slotted Shelving Med no Rail Bracket Low-med no Hand Rail High no Wood all yes ---- Triangle ~ 0 v low uber-easy Braced ~ 0 Med easy Sheet Braced ~ 0 Med Med Lattice Braced ~ 0 Med an eternity Compound 10p Med easy Leg £1-2 High uber-easy Wedge ~ 0 Low awkward Square Frame ~ 0 Med so-so Multi-braced ~ 0 High so-so TV bracket £1-3 High easy Multimaterial £1-2 Med/hi easy Bookshelf £4-8 Med lot of cutting Plastic ------- Ring low low med

- 'DIYable' refers to ease of construction using only the more popular DIY tools, no welding kit or sheet metal bender.

- Prices are only ballpark.

Terminology

The following terms are used here:

___________ |___________| <----- Support | | / / | | <---------- Spine | | / / | | / / | | / / <----- Brace | |/ / | | / | |/ |_|

Metal Brackets

London Brackets

- Very popular

- Low cost pressed metal brackets

- Medium load ratings

- Unattractive

- Widely available in grey and white finish

- Barely sufficient strength for mass storage

- Brackets occasionally parallelled for greater load rating

High Load Bracket

Brackets of any design with high load rating.

Microwave Bracket

A metal bracket with high load rating, extendable support and no brace. These are made from thick sheet to achieve the required strength, and thick steel requires much heavier equipment to work it, hence the high price.

TV Bracket

Large metal high load bracket with swivel mechanism & equipment tray. Often extending and can fold flat against wall. Some have a second tray or strap for a video recorder.

- Can be used as a movable desk extension or bedside tray.

Mitred Bracket

A corner welded bracket. This enables larger profile steel to be used than bent brackets, giving higher load rating.

- High to very high load rating.

Gallows Bracket

- Braced metal bracket

- Generally more decorative than strength oriented

- Added strength from the brace, but these are often not high load rated brackets.

Corner Brace

Flat strip is bent 90 degrees to form a simple miniature bracket.

- Well suited to very small brackets upto a couple of inches.

- Such brackets are readily available from BMs for pence.

- Small ones can be made from scrap if stocks run out. (grind the edges & corners for a few seconds to avoid cuts)

- Can support heavy loads if the front of the load is also separately supported

- Only support very light loads if the front of the load is not separately supported

- Rounded corners or safe edge minimise the chance of snagging clothes or scratching hands.

- Related items that look more or less like corner braces can also be used, such as stretcher plates etc.

- If you want extra strong corner braces, these can be made by slicing heavy duty angle iron.

The angle brace is a short rounded version of the corner brace.

Braced Strip Bracket

This is as the corner brace above, but with an extra bracing section.

______ _____ | / | ) | / | / | / | / | / | / | / | / || || || ||

- The lower fixing screw also fixes the brace to the backplate.

- The front part of the bracket should be bent before the rear.

- A hole in the front enables screwdriver access for the upper screw

- Twisting the brace 180 degrees stiffens it and strengthens the bracket further.

Shrinkage Bracket & Stretcher Plate

Miniature bent sheet metal brackets

- Shrinkage bracket has 2 fixing slots at 90 degrees, allowing some movement.

- Stretcher plate has slots in one direction allowing movement.

Triangular sheet bracket

________ _|........| | : / | : / | : / | : / | : / | : / | : / |_:/

- Cut sheet metal to the above template.

- Fold 90 degrees along the dotted lines to form a triangle with right angle flaps along 2 sides.

- Drill 2 holes in each flap for fixing.

- Simple & cheap if you have basic metalwork equipment.

- Thin metal brackets are easy to make, thicker ones less so.

- Load rating varies widely depending on material and size.

Where highest possible load rating is desired, adding a 90 degree flap to the 3rd side increases rigidity, but is not as easy to fabricate.

Template:

________ _|________| | | /\ | | / / | | / / | | / / | | / / | | / / | | / / |_|/ / \/

Floating Shelf Bracket

These brackets lack a spine and slot entirely inside the shelf after fixing, thus being invisible when the shelf is fitted.

Load rating is low to medium, and the shelf must be thick to accomodate the bracket internally. The lever effect puts relatively high stresses on the wall when the shelf is loaded, requiring a strong fixing. Unsuitable for weak walls such as strawboard.

Splash Bracket

These consist of a short bulbous spine & support with an extra lip that sits above the shelf. These support a shelf only at the rear, giving low load strength.

Bookcase Supports

These consist of perforated strips fixed to the carcass plus metal tabs to support the shelves.

- Load: medium

- Adjustable

Slotted Shelving Strips

Popular adjustable bookshelf support systems. Consist of slotted metal strips plus shallow metal brackets that slot into the strips.

- Adjustable

- Medium load rating

- Twin slot steel strips bear more load than single slot or aluminium strips

- Wood versions also available

- Supports usually survive single point fixing failure

Rail Bracket

Extruded strip providing support at the back of the shelf. The strip should run the full length of the shelf for good support.

- Medium load

Hand Rail Brackets

2 metal discs joined by a cranked metal rod. Popular for supporting stair handrails.

- High load rating for loads close to wall

- Pleasant appearance

Wooden Brackets

Wood is not as strong as steel, so wooden brackets are bulkier to achieve the same strength. This makes them a good deal more visible. Also wood is relatively easy to shape, and because of these factors wooden brackets are often decoratively styled.

Wooden brackets are normally braced. Where lower profile is necessary, choose metal.

Simple Triangle Bracket

/

/

/

|_

___________

| .'

| .'

| .'

| .'

| .' <----

|.'

This is just a triangle of wood, minimum 3/4" thick. The 2 arrows show the position of screws, for which clearance holes are drilled.

The main advantage of these brackets is that they can be made in seconds.

- Low load rating

- Requires large screws (3" for a 5" bracket)

- Very simple

- Extremely quick to make

- Suitable for very light & small shelves only

- Small bracket sizes only

- When these brackets are fitted under the supported load, maximum strength is obtained with grain horizontal.

- When fitted above the supported load, maximum strength is obtained with grain parallel to the 45 degree side.

Fitting them with the bracket above the supported shelf:

|'.

| '. <---- screw

| '.

| '.

| '.

|__________'.

_

|

\

\

screw

Variations

- Thick Plywood improves strength

- Quarter round shape may be used instead of a triangle.

- A fairly large round hole may be made in the centre of the bracket

- A square bracket supports 2 shelves, but load capacity is very low. Sufficient for spice jars etc.

screw

/

/

|_

_______

| |

| |

| |

|_______|

_

|

\

\

screw

_____ | / | / | ( | \ |____\

_______ | ___ | | | | | | |___| | |_______|

______ | | | /\ | | / \ | | \ / | | \/ | |______|

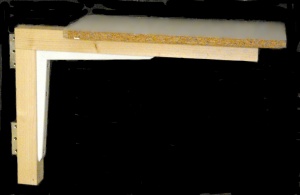

Braced Bracket

Most popular wooden bracket.

- Simple to make

- Good load rating

2 variations are shown

___________ |___________| | | / / | | <----/ | | / / | | / / | | / / | |/ / | | / | |/ | | <---- |_|

___________ |___________| | | / / | | <----/ | | / / | | / / | | / / | |/ / | | / | |/ <---- |_|

In the 2nd bracket, the lower wall fixing screw also attaches the brace to the spine.

Sheet Braced Bracket

___________ |___________| | | / | | <----/ | | / | | / | | / | | / | | / | |/ | | <---- |_|

Here ply is used as a brace. The spine is wider than the sheet to enable the bracket to be screw fixed to the wall.

- Use glue or multiple piloted screws when assembling

- Quarter round shape may be used instead of a triangle

- Stepped shapes can also be used for a somewhat 1930s look.

_____________ |_____________| | | | | | <--- __| | | | | | __| | | | | |__| | | <---- |_|

Lattice Braced Bracket

_____________ |_____________| | | . . __) | | * <> /' | | _ ( | | (_) ) | | /~ | |_/ |_|

The supporting triangle is latticed and may be made into a fancy shape to give a light and pleasant appearance.

- Wood grain of 1 piece latticework should be horizontal for best strength

- Using ply for the latticework makes the bracket stronger.

Compound Bracket

This uses wood and steel together to achieve good strength, a simple quick to make design and low cost.

This is an easy way to make large brackets with high load ratings from standard London brackets.

_______ |_______| <--- wood ,-- / / | <-/ / ---- Metal bracket | / / / / <--- wood brace / / / / / /

This is of course a variation of:

___________ |___________| | |,-- / / | || / / | || / / | | / / | | / / | |/ / | | / | |/ | | |_|

The metal bracket is able to take much higher than its rated load because

- Nearly all the loading is close to the wall, avoiding a lever effect

- The load is applied to the strongest part of the bracket

- The weakest part of the metal bracket is effectively bypassed

The compound bracket takes even more load because a lot of the load is carried by the brace and wooden support.

Timber may be anything from 2 x 1/2 for lightweight use to 2x3 for heavyweight loads. 2x2 is big enough for almost all household loads.

Leg

Legs are sometimes used in lieu of brackets. They are a simple way to achieve a high load rating.

Leg Support:

________

|________| <-- Load

_ |

| | <-- Mini bracket on wall

|

| <-- Leg

|

Wedge Bracket

A cube of timber is cut into 4 to make 4 wedge shaped brackets. Describing and drawing are both difficult, maybe someone will come up with a clearer diagram later.

Hold the cube of wood like so, and cut along the dotted lines as shown:

/|\ / | \ /__|__\ ...... cut horizontally \ | / \ | / \|/ : : cut vertically

Each resulting bracket has only 4 sides. In use the end user sees a wide angled wedge.

/|\ / | \ View perpendicular to the brace edge \ | / \|/

_______ | / | / Side View of bracket | / |/

________ \ / \ / Rear View (as if looking through the wall) \ / \/

- Suitable for small decorative brackets.

- Invisible fixings recommended.

- Relatively big timber needed - a 4x4x4" block makes 2.7" brackets

- Nearly impossible to clamp for cutting

- The block may be held in place with screws, and the one of 4 brackets with holes in then sacrificed.

Square Frame Bracket

These are braced square frames, and may be used to support 2 shelves, one above and one below.

- Strength depends on bracing detail.

Examples:

__________ |__________| | | / | | | | / /| | | | / / | | | | / / | | | |/ / | | |_|_/____|_| |__________|

_________________ |_________________| | |// \\| | | |/ \| | | | | | | |\ /| | |_|\\_________//|_| |_________________|

____________ |____________| | |\ \ / /| | | | \ \/ / | | | | \/\/ | | | | /\/\ | | | | / /\ \ | | | |/ / \ \| | |_|_/____\_|_| |____________|

___________________ |___________________| | | //\\ //\\ | | | |// \\ // \\ | | | |/ \\// \\| | | |\ //\\ //| | | |\\ // \\ // | | |_|_\\//____\\//__|_| |___________________|

___________________ |___________________| | | | | | | | | | | | | | |______| |______| | | |______ ______| | | | | | | | | | | | | | |_|______|_|______|_| |___________________|

__________________ |__________________| | | // // // /| | | |// // // //| | | |/ // // // | | | | // // // | | | | // // // /| | | |// // // //| | |_|/__//__//__//_|_| |__________________|

__________________ |__________________| | | /\ /\ /\ /| | | |/ \/ \/ \/ | | | |\ /\ /\ /\ | | | | \/ \/ \/ \| | | | /\ /\ /\ /| | |_|/__\/__\/__\/_|_| |__________________|

_______________ |_______________| | | \\ // | | | | \\ // | | | | \\ // | | | |==== O ====| | | | // \\ | | | | // \\ | | |_|_//_____\\_|_| |_______________|

etc

Multi-braced

_______________ |_______________| | |/ / \ \/ / | | / \/ / | |/ / / | | / / | | / / | | / / | |___/ / | |__/ / | | / / | |/ / | | / | |/ |_|

This construction increases the strength of large brackets primarily by reinforcing the joints, but triples the fabrication work. For high load applications only. Glue & screw for max strength, using a glue intended for loadbearing use.

- High load

- Large Brackets

Mixed timber/metal bracket

Its possible to mix metal and timber in one bracket. This is sometimes done to gain the size of a wood bracket with the strength of a metal bracket. Usually only the top support of the metal bracket is thus extended. In the picture above a wooden spine was also added to enable a custom fixing and improve appearance.

When a bracket is extended this way, the load is levered on the metal bracket, and a doubling of the length of the support gives the finished bracket half the load rating of the metal bracket alone.

TV Bracket

The exact configuration of a TV bracket depends on what movement is wanted from it, if any. The one pictured

- rotates on door hinges to move the monitor toward or away from the user

- the shelf has trimmed corners for safety & comfort

- the design is braceless to clear items placed below it.

Note the load rating should generally take into account people falling against the bracket, not just the weight of the tv.

Where hinges are used as above, avoid any low friction type of hinge. 3" door hinges were used for this LCD TV shelf, a CRT would require several 4" hinges for a large set.

Bookshelf strips

__ ___

| / \ |

| /_ _\ |

| / \ |

| /_ _\ |

| / \ |

| /_ _\ |

| / \ |

|_/ \_|

_______

/ \

/_________\

Carcass strips and moveable supports

These support bookshelves mounted in a furniture unit. Each end of the unit has 2 zigzag upright strips made of about 3x1 permanently fitted. Trapezoid pieces are placed in the cutouts to support a shelf.

A lot of cutting is needed. To be practical you need a machine with some sort of basic ad-hoc jig to allow the cuts to be made rapidly and repeatedly. Trying to make these with a jigsaw is not a good plan.

Timber Bracket Information

Grain

Avoid the main load stresses pulling timber across the grain, as wood is weakest in tension across the grain. Grain orientation is thus important.

Timber Types

Softwood

Most wooden brackets are made from softwood. It is very cheap and readily available. In most cases the wood is already to hand and costs nothing.

Hardwoods

These are generally significantly stronger than softwood, but are still weaker across the grain than along it. Hardwoods are mainly chosen for appearance and durability.

Ply

Wood brackets may be made from plywood to substantially increase their strength. Plywood has good strength in 2 directions, whereas plain wood can split due to weaker tensile strength across the grain. Beware of using non-WBP ply in damp locations, this can result in the ply delaminating where screws are used, and thus failing.

Chipboard

Chip is a relatively weak timber product, and is not suitable bracket material.

Assembly

Wooden brackets may be nailed, screwed or glued.

- Nailing is a weak option

- Screws enable immediate use

- Gluing brackets saves time when making quantity. However a glue suited for load bearing applications should be used, or failures may occur. Its not worth skimping here, one failure can cost more than the glue.

- Glue plus screws is the strongest option.

Screws should penetrate as much depth of the wood as possible to minimise the risk of splitting.

Pilot Holes

Where wood brackets are assembled using screws, clearance & pilot holes should be drilled to avoid splitting or prestressing the small size wood. If no pilot holes are used, choose thin shank screws and reject anything that begins to split.

Plasterboard screws are a good option, with these it is not usually necesary to predrill a countersink.

Invisible Fixings

- For wood brackets only

- Screw fixing screws into the rear face of the bracket, leaving around 1.5" protruding

- Cut heads off screws

- Drill fixing holes in wall

- Put resin in the holes

- Press the brackets into position

- Support each bracket with a stick while the glue dries

For very lightweight brackets, it may be simpler to screw a wood strip to the wall then glue the bracket to it.

Plastic

Commercial plastic brackets are seen on occasion.

Ring Brackets

Rings cut from PVC pipe are solvent welded into bracket shapes.

_ _ _ _ _ _ _ __ _ (_)(_)(_) (_)(_)(_) (_)/ \(_) (_)(_) (_)(_)(_) _( )_ (_) (_)(_)(_) (_)\__/(_)

_ _ _ (_)_(_)_(_) _(_)_(_) (_)_(_) _(_) (_)

- Light duty

- Can be painted wth household gloss topcoat

- Good for lightweight shelving in kids' rooms.

There are several options for fitting:

- A fairly large pipe size enables standard fitting method. Hexagonal screwheads are driven with a socket or ratchet spanner, or allen heads with an allen key.

- Where small pipe rings are used, keyholes can be cut in the plastic and the bracket is slotted onto the screwheads.

- The first row of rings are glued together and screwed to the wall. Then the remaining rings are glued in place. (To remove the bracket in the future, cut it & unscrew.)

- Deep screwdriver access holes are drilled from the front

- Deep screwdriver access holes are drilled from the top, thus will be out of sight once fitted. This means driving the screws into the wall at around 45 degrees.

- The column of rings next to the wall is wider and tapered, giving the bracket this profile seen from above:

\______

|

______|

/

Ring size

- Bracket strength is proportional to the length of the rings.

- Bracket rings may be tapered or stepped sizes for added visual effect.

For more information and ideas, see Make Things from PVC Pipe