Drawers

Material

Most modern drawers are made from a melamine veneered chipboard camlocked together. The 4 drawer sides are grooved near the bottom, and a 3mm hardboard base sheet sits loose in the grooves. Metal runners sit in cutouts along each side.

Better quality drawers may be made from wood. Some are dove tail jointed. These often have a plywood base. They often run on wood rails. If properly made, wood furniture can last centuries. Flimsy wood furniture can usually be improved to make it robust enough to last.

All plywood drawers are sometimes seen on old furniture. If well constructed these can be especially tough.

Metal drawers are not currently covered here.

Drawer kits

Kits are available containing drawer sides connected to runners. These can be fitted into all sorts of spaces, and only require a front, back and base to be added once in place. No grooves need to be machined for the drawer base, it sits on a lip running down each side. These kits make drawer construction quicker.

Runners

From worst to best...

Plastic strips

Low cost plastic strips are used in economy furniture. These are moulded plastic strips fixed to the carcass, usually with staples.

They are weak when the drawer is fully open. Strength can be improved with additional fixings, with more at the front than the rear, but they won't become properly robust.

This design is prone to the drawers coming off the runner due to lateral bending of the carcass. This can be improved by adding lateral restraint of the carcass to prevent the sides moving or bowing outwards. Sometimes just tightening of carcass fixings is enough, sometimes a strip of wood, metal or wire can be added running across near the front at around half way up.

Metal inset runners

Most drawers use low profile metal runners sat in cutouts along each side of the drawer. Ball bearings provide very smooth action. They last longer than plastic strips, but generally fall apart in time. Once one fails more will follow, and the cost of replacing them all is often uneconomic. You might get another few years by replacing 1 or 2.

Bottom fix & side fix metal runners

Non-inset runners may be used where insetting into a groove in the sides of the drawers is impractical. They take up more space, and on kitchen units they might foul the door below. These typically use plastic wheels & have less load rating & robustness than inset metal runners.

Wood rails

Real wood rails are much more robust than other types, and if done properly should last a lifetime. Simple and effective, but not low friction, and there is lateral movement in use. Polishing the sliding parts with soap, wax or silicone polish makes them run a bit better. Simple wood rails don't prevent a drawer being pulled out, blocks or small metal braces can generally be added to prevent that eg for toddlers' rooms.

Tiny wood rails that fit in drawer side slots aren't nearly as robust.

Castors

Castors are used on underbed drawers that aren't connected to the bed frame. Large castors eat into the available height, small ones bog down in carpet and catch on uneven floorboards.

Load rating

The load rating of runners affects life expectancy in real world use. IME most fail at some point, except proper wooden rails.

Sizes

Metal runners are commonly available in 40cm, 45cm and 50cm lengths. Use the correct length to maximise the opening distance. A shorter length can be used if necessary, the drawer opens less distance.

Broken runner conversion

The best option when runners fail is normally to add wood strips under each drawer as runners. This is easy, free or nearly so, and should last forever. A minority of drawers are full height all round, leaving no space to do this. These can be converted to wood rails if sides & back are cut down a bit.

Drawer Bottoms

Material

Most drawers use 3mm hardboard for the bottom sheet. This is usually veneered to give it a wood-like or white appearance. Hardboard isn't fully rigid, but the all round edge support helps keep it near enough flat. Normal loading gives you a sagging bottom, heavy loading can make the bottom pop out. Water causes bad staining as the colouring in the hardboard migrates.

Thin plywood is a stronger option used in better quality drawers. It's thicker, stronger, and fully rigid.

Solid wood drawer bottoms are much thicker and strong, and tend to be found on old fashioned furniture and high quality furniture.

Support

Drawer bottoms should be supported on all 4 sides. Anything less risks failure.

Gluing

Wood drawers (eg pine or oak furniture) aren't completely dimensionally stable, and the bottom should never be glued in place in these, or splitting can occur.

Chipboard (eg melamine, imitation wood & ply) drawers are dimensionally stable, and gluing the bottom in place improves strength.

Knobs

A wide array of knobs is available, in both 1 hole and 2 hole fixings.

Sometimes it's possible to restyle furniture by doing no more than replacing the knobs. New knobs and sometimes an accessory or two can make a chest of drawers look very different, and can transform cheap, tired or unfashionable furniture.

Non-matching but similar furniture may be turned into apparently matching sets by fitting a unified knob style. This is mainly useful for melamine furniture.

Generally plastic knobs are weaker than wood and metal, and better avoided where heavy loads are anticipated.

Wood knobs may be waxed, oiled, varnished or painted. Uncoated wood is harder to clean.

Round holes or short sections of very thick rope are alternatives to knobs occasionally seen. Making the bottom of drawer fronts finger accessible allows a knobless minimal look.

Strength

Strength is an issue when domestic drawers are used for heavy loads, such as DIY tool storage. Such tasks take most such drawers beyond their design load rating. The usual weakpoints in flatpack drawers are thin drawer bottoms, weak runners and lateral spread of the carcass.

Thin bottoms can be cured by:

- gluing the hardboard bottoms in place

- laying thin plywood on top of the existing bottom, and attaching the ply to the drawer sides using plastic blocks or wood strips

- disassembling the drawer, rerouting, fitting a ply base and adding extra support to the sides as above.

- Fixing strengthening strips across the interior base, and attaching them to both drawer bottom and sides.

Weak runners can be fixed by:

- Adding more screws to plastic runners

- Adding a secondary wooden runner strip under the drawer base

Lateral spread can be prevented by fitting tie bars across the carcass. These can be rigid bars or just iron wire. They need to be positioned to avoid fouling the drawers. Small metal braces can also work, but check clearances, they don't always fit.

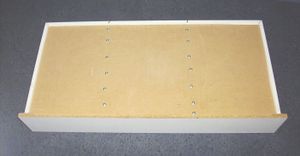

The pictures show a set of drawers able to take several times the load they were originally designed for due to fitting of additional fixings to the plastic rails, addition of wood secondary rails, lateral carcass restraint with iron wire and added bars to the drawer bottoms. None of the extra carcass hardware is visible in use, only the bars inside the drawers show. Non-visible drawer reinforcement by using plywood would take more work.

Special purpose drawers

Ironing board

This looks like a drawer, but contains a folded ironing board. a place to put a board away can be useful in a very small kitchen, but they offer no choice as to position of the board in use.

Secret drawers

Non-obvious drawers are occasionally enocuntered on old writing desks. They may be anything from 1/2" - 2" deep. The concept may be used to provide a little extra space in excessively compact rooms. They're very simple to make, being little more than sheet material with a front strip attached. Where lateral carcass support is lost, the wooden restraint strip may be replaced with thin metal strip.

Fake drawers

These are fixed panels that look like drawers. They often have a drawer handle. These are sometimes used in front of sinks. Fake drawer fronts are sometimes connected to the cupboard doors underneath them. Fake drawers are a means to make an unopenable space look well utilised and match the rest of the units.

Stair drawers

These are used on small boats where space is at a premium. The space under each step is a drawer, accessed by pulling it out onto the step below and in front of it.

These aren't used in houses as they're a safety risk. A lot of people are seriously injured in stair falls each year.

Dividers

Drawer dividers may be used to keep different types of item apart, or to facilitate tidy storage of eg socks, cutlery etc.

Plastic divider trays

Cutlery trays are popular. Might not fit your drawer, no layout flexibility, but cheap & instant.

Plastic dividers

User configurable plastic dividers come in straight interlocking strips. Flexible layout, but take time to assemble, and cost more. Can be made from stripwood or cladding.

A wavy corrugated type of divider is also available. The compartments are good for stuffing socks, but are the wrong shape for most other tasks, and no user reconfiguration is possible. These can also be used on walls, and where space is extremely tight even built into stud wall cavities.

( )( )( )( )( )( )( ) ( )( )( )( )( )( )( ) ( )( )( )( )( )( )( ) Corrugated divider

Tupperware type boxes can be used to create lidded compartments.

Mini trays can be placed to create compartments. Cut down small cardboard boxes do the same job, less prettily.

Fruit tray inserts (from apples, melons etc) will separate some types of item. They aren't robust, user configurable, or suitable for many things, but they're free and have occasional uses.

Fronts

Drawer fronts can be readily replaced on kitchen cabinets. This along with any carcass repairs can be far cheaper than a total refit.

It's also possible to replace the fronts on some veneered chipboard furniture. However they aren't designed for this so on some units it's not so easy. Timberboard drawer fronts give units a mainly pine look, with some white as well.

Locks

Key operated drawer locks are occasionally seen, and can be bought from builders merchants and retrofitted. Don't expect good security though.

Childproof catches can prevent toddler access, if you're lucky. Of course they have a lot more time to figure them out than you do.

Soft closers

These provide a slow graceful closing action, and are currently popular on new kitchen units. Failure rate & results remain to be seen.

Self closers

Self closers are rarely needed or used on drawers.

If needed they may be implemented with fishing line attached to the drawer rear, passing through an eye screwed into the carcass, and a weight on the line. Putting the weight and line behind a false back makes it tidy. A spring in the line reduces shock forces. The thin line is hardly noticeable if you use clear or smoky nylon monofilament. This type of self closer only works with metal runners.

Liners

Liquids can spill & perishables can rot, badly staining drawers. To reduce the risk drawers may be loose lined with paper, vinyl wallpaper or plastic film. The latter are non-permeable, so there is more chance of the spill drying before it reaches the drawer. Paper upper side and plastic lower (eg upside down vinyl wallpaper) gives the most spill retardation.

Something different

If you fancy something special, curvy tilted drawer units can be made on a bandsaw.