Hex bits

Hex bits make life easier, quicker and cheaper, and are a must for almost any DIYer.

- By separating the screwdriving bit from the handle, they enable minimum cost worn bit replacement.

- By using an easy push-in fitting, they enable instant replacement of bits in tools.

- The wide range of hex bits available and the instant fitting makes repeated swapping between screwdriver bit and drill bit a doddle.

- The minimised cost of replacing only the driving bit enables even the humblest DIYer to buy good quality bits.

- The small size of the bits makes storage of a wide range of bits easy and convenient.

- The low bit cost makes pushing the bits hard not a problem

Types

A great range of hex bits is available, including:

- Screwdriving bits of every conceivable type

- Socket adaptors

- Nut drivers

- Hook & eye driver

- Drill Bits, in small to medium sizes

- Extension bars

- Quick release bit holders

- flexible drive shafts

- 90° drive adaptors

- Multi-section drill bits - can drill pilot, clearance and countersink in one go, but the short sizes and fixed size transition point make these a lot less useful than they first sound.

- Titanium coated bits for longer life than steel

Screwdriver bits include:

- All the usual bit types

- All the familiar security bit types

- Drywall bits - a shroud limits penetration

- reversible double ended bits

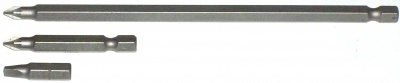

- 1" bits - most common size

- 2" bits

- 6" bits

- bits intended to drive screw heads at an angle (eg upto 15°)

Head Identification

Use in

- manual screwdriver

- stubby screwdriver

- codless screwdrivers & drills

- nearly all non-SDS drills

The bits will fit in a standard Jacob's chuck as well as in a hex bit holder. (FWLIW they can also be fitted to a socket bar using a 1/4" socket.)

Where access is so bad that only an inch of room to work is available, these bits can, if inconveniently, be used in waterpump pliers or mole grips. This can occasionally undo screws where nothing else will fit.

Holders & extension bars

Holders are available in short and extension formats, as well as manual screwdriver handles.

Waggle

Extension bars tend to introduce waggle, as hex bits aren't clamped where held. Putting an extension bar into another extension makes it worse.

How bits are held

Holders may hold the hex bit in any of 3 ways:

- Magnetic - instant easy pullout of bits, but bits occasionally fall out

- Sprung ball - a little more force required to remove

- Locking - a collar is pushed back by hand to release the bit. These are the ones to use with drill bits, otherwise the bit gets left in the workpiece as you pull out. They also prevent bits falling out and being lost, but are less convenient for frequent bit changes.

Driving

Slotted heads

Very low driving speeds reduce the tendency to jump off the screwhead, and minimise damage when it happens. Progress is usually slow when driving slotted heads.

Philips & Pozidriv

The 2 look similar, but aren't the same. Picking the right bit type gives much better grip with size 2. With size 1 the difference is less, and philips and pozi are usually swappable.

Slip

Most bit & screw damage occurs when the bit jumps out of the head recess and continues to rotate, going in and out noisily as it turns. This is called cam out. Apply enough force to prevent this. Philips heads are more prone to it than pozi.

Mains drills

Most of us have cordless drills now, but a mains drill can be used as a scrwedriver if necessary. Mains drills are not designed to drive hex screwdriver bits. They will do so happily, and with lots of speed and force, but control is very poor, with a lot of overrun.

- screwing to the right depth is hit and miss until you master the skill. Until then, expect some very recessed screws, which is no good for many applications.

- The drill doesn't stop when released, the drill continues to rotate on cam out. This kills hex bits prematurely, and ruins stuck screws. Lots of force and reduced speed help.

If you're not planning to get a cordless drill, a mains drill will do for rough work with a bit of care, but cordless are vastly better for screw insertion.

Quality

Quality is an issue with hex bits, with a lot of junk grade bits on sale.

Bits found in cheap kits, pound stores, special offer bins and so on are usually of dismal quality, often only surviving half a dozen of screw insertions when used with a power tool. Some don't even fit the screws they're designed for. Buying these is a waste of time for most of us.

Hardened chrome vanadium bits are similar quality to good manual screwdrivers, and will last a fair time in DIY use before they cease to perform properly. However these bits will see a fair rate of failure when used for heavy trade use, such as construction.

Titanium coated bits can last longer than steel if the underlying metal is of good quality, something that can't be assumed.

Diamond encrusted bits grip the screw recess better, resulting in less slippage and thus less bit damage. Brands include Wera.

Storage

Bit kits usually come with some sort of storage device, often either a plastic block or a small book format folding case. Kits including larger items (usually drill bits) have the advantages and disadvantages of everything being in one case.

There are several popular bit storage formats:

- Screwdriver with half a dozen bits arranged around the shaft. The bits are pushed into rubber which holds them loosely. These are convenient at point of use.

- Ditto with bits stored inside handle. Less convenient, but unlikely to lose bits if knocked about. Good for tools used only rarely.

- Dial box - a round box a few inches across storing upto a dozen bits. Dial the cover to get to the wanted bit. Breakable, limited capacity, but pocket friendly when going up a ladder

- Multi compartment tray - good for storage of a restricted range of bits in large numbers. Good for site storage, but ensure the latch is burstproof, and the tray always left closed!

- Paperback sized folding cases - Common cases for bit sets, these are a good way to store a small collection or a selection of bits. The case can be relabelled with dymo tape or a diagram stuck inside the lid. Painting each row or section a different colour (household gloss paint) can speed up finding the bit you want.

- Large format folding cases - typical cases for large drill bit sets, containing a mix of drill bits & screwdriving bits. Again the bits carried can be changed and the case relabelled as above.

- Custom large format folding cases - sheets of foam, polystyrene, drilled wood etc can be incorporated into a portable case to allow storage of any number and arrangement of bits. Many bits can be held individually, and an area for closed containers can be added for bulk storage. Emphasis should be placed on preventing spills. External rubber feet can reduce peak forces, reducing risk of damage & spills.

Regrinding

Regrinding can rarely be useful to make a bit to fit a special screw recess, when a suitable driver can not be located. A die grinder with carbide tools (grey) can be useful. Care should be taken not to heat the metal too much, or it will soften and become not very useful.

Dimensions

Hex bits use a 1/4" hexagonal fitting. (There are also larger sizes sometimes seen used with impact drivers, but these aren't common.)

Most screwdriving bits are 1" long. 2" & 6" are available for more reach or just straighter reach when the screw is close to some obstruction. The variety of long bits is more limited.

Bits lost in handle

Some tools have a deep bit holding recess designed for 2" bits, and 1" bits disappear inside. These can be converted to using the common low cost 1" bits by filling part of the depth of the recess.

- One simple remedy is to use 2 thin screws, such that the 2nd screws down the side of the first, locking the pair in place.

- Another possibility is to cut a dead bit to the required length and push it down the recess, holding it in with resin glue or a slip of paper down one side.

Limitations

Recessed screws

Recessed screws in plastic appliance cases often sit in narrow deep holes. Hex bit tools are often too fat. Long bits are one solution, but sometimes these don't fit. 1/8" hex bits or a conventional screwdriver work better.

Waggle

Hex bits aren't clamped in the holder, so waggle a bit. With drill bits this causes less than perfect behaviour, and limits them to low-medium speeds.

Drill bits

Decent hex shank drill bits are machined from one piece, but some are in 2 pieces just glued together. The latter come loose if significant force is applied, use such bits for light use only if at all.

Safety

When pushing bits hard, its possible for a lump to shear off the end, creating an uncentred sharp point, and throwing the bit off the workpiece. Keep hands (and legs) away from the bit when pushing them hard.

There is also the usual issue with slotted bits that they like to slip off the screwhead, and have sharpish corners.

One of the functions of the )( section of the bit is to deflect very slightly if necessary, helping to avoid the tip shattering in some circumstances.