Microwave repair

Some microwave faults are fairly easy to repair.

Safety

Microwaves contain more dangers inside the workings than most household appliances, and even experienced techs have occasionally been killed working on them. As with any DIY task, some competence is required.

If in any doubt about your ability to do such work safely, don't.

Responsibility for safety is entirely yours. This article gives info, but anyone can edit it at any time, opinions on safety do vary, and in real life assumptions get made.

Capacitor discharge

The HV capacitor should always be safely discharged before working on a nuke. They're normally designed to discharge themselves, but when they fail to the results are liable to be deadly.

Attach a wire from the metal case to a screwdriver shaft (one with an insulating plastic head!). Check its connected to the case and prod both capacitor terminals at the same time with the screwdriver. Repeat.

Another way to do it is with 2 insulated screwdrivers and no wire.

Live working

We can't recommend it. A mains shock has only a slight risk of death, but over a thousand volts at high current in a microwave is a very different story.

Bodges

Sometimes buying the right parts isn't worth it, but there are other options that work. Ones that are safe & usually work are mentioned here.

Fault Finding

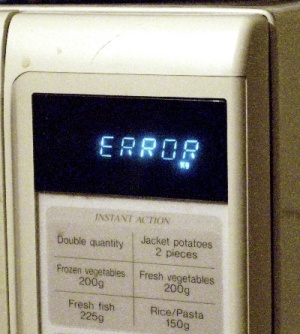

No sign of life

Usually the main fuse failed, often due to an interlock fault. This often takes out the interlock resistor. Don't replace the fuse until correct operation of interlock parts has been verified, and the interlock resistor tests good.

Sometimes the interlock fail is caused by door misalignment. Adjust hinges slightly so it aligns correctly.

Sometimes door realignment is beyond the end user. An easy bodge is to glue a bit of a sheet material to the uderside edge of the door so the shim lifts the door slightly to its correct position as it closes.

Burning waveguide cover or magnetron cover

Nukes either have a metal waveguide to conduct the microwaves into the cooking cavity, with a waveguide cover, or the magnetron is positioned right next to the cooking cavity with no guide, and a moulded plastic magnetron cover.

Burning waveguide cover

In waveguide equipped ovens the microwave rf energy enters the cooking cavity through a waveguide cover made of mica or fibreglass. The cover is on the roof or high up on the side of the cooking cavity. If burnt muck builds up on this it eventually arcs and burns.

Remove the burnt waveguide cover and check the oven now works properly, heating only water. Don't continue using it without its cover, or it won't last long. Cut a new piece to shape and fit.

Use waveguide cover material, not random plastic. The wrong stuff is likely to catch fire, and deposit muck in the waveguide, which is very difficult to clean out - and with muck in there, the oven simply shorts out.

Occasionally the oven still arcs with the waveguide cover removed, due to muck in the mouth of the waveguide. Remove muck and it should be good - but you need to be thorough.

Burning magnetron cover

The problem is much the same as a burning waveguide cover.

If you catch it soon enough, with little damage done, clean the plastic cover thoroughly, cut out any carbonisation and refit.

If the cover is beyond repair, it can be replaced with a new one that fits the model.

A bodge option is to just not refit a cover. Any muck that lands on the red hot magnetron is instantly burnt off, but muck can over many years build up around it and eventually short the microwave output or burn. This situation is a real pain to sort out, access is very difficult.

Uneven heating

No nuke is perfect at this, but excessively uneven heating creates a risk of food poisoning. Causes are turntable not turning, and (when fitted) stirrer not turning.

The most even cooking machines have both turntable and stirrer.

Turntable doesn't turn

Usually the turntable isn't engaging correctly with the turntable motor spindle, often due to the wrong bits being used. Get the right part that interfaces the 2, or get the right turntable, or modify a plastic part to get them to work with each other.

If the turntable motor doesn't slowly revolve (at 3 or 6 rpm), it can be replaced with one from almost any other microwave.

Access to this motor is via an access flap under the machine. Some covers are screwed on, some you have to cut out and refit in a different position afterwards with screws. Refitting these takes patience.

If you find there's no motor there, you might have a belt drive turntable. Some old machines geared down the main fan and ran turntable/stirrer by long rubber bands. For a band of suitable dimensions, look at suppliers for other electronic equipment that uses bands/belts. Stationery rubber bands often work, and some last years - no promises though.

Occasionally nukes let the user switch off the turntable to allow maximum use of the cooking space. These machines always have a stirrer. Even less common are machines that come with a temperature probe, when its plugged in the turntable is stopped. These features are fairly unusual, but its probably worth checking power is reaching the motor.

Stirrer doesn't turn

Generally these are driven by the air current used to cool the magnetron. If they don't rotate, the food cooks unevenly. Either the central mounting is dirty and sticking, or the air path is amiss, typically due to roof lining fixings coming out. The amount of force the air puts on the stirrer is slight, sometimes stirrers turn freely by hand, but not quite freely enough to turn in the airflow.

Remove roof lining, clean stirrer mounting thoroughly, refit lining. Don't oil the central mounting, it'll only clog with dirt.

Some old machines geared down the main fan to run the turntable/stirrer by long rubber bands.

Fails to cook

Everything looks like it works, but it fails to heat food. A fault with any of the following will do this:

- diode

- HV fuse

- capacitor

- control system

- transformer

- magnetron

All the above are frequent offenders, listed most to least common.

The easiest way to find the problem is test each component on the resistance range with a multimeter. The problem is usually a shorted or leaky component, or an open HV fuse.

If you can't fault find, but have a scrap donor machine and are willing to try something,

- the HV diode is the most frequent failer, easy to replace, and in most cases one from a random nuke will do. It must be fitted the right way round, or the oven won't cook.

- HV capacitors are also a common fail, often easily swappable, and a random swap often works but no guarantees.

- HV fuses also often fail

Fire

Microwave food fires look bad, but if the door is ok and the outside of the machine's ok, repair is generally straightforward. Clean the cooking cavity out thoroughly and the machine usually works fine again.

Often its necessary to replace a fried waveguide cover or roof lining. You can test it first without these. If the cover's reusable it needs a very thorough clean, or will fail.

Electronic control faults

Seldom worth repairing. Mechanical controls (rotary knobs) are a fair bit more reliable.

Mechanical control faults

These don't often fail. Burnt switch contacts can prevent cooking. Clean the switch contact surfaces with extra fine sandpaper, once they're clean they're good. Other faults are generally very visible when the machine's powered up.

Noise

The 2 usual causes of excessive noise are

- Side of metal case affected by transformer's magnetic field

- put padding between the 2 to stop it resonating.

- putting a small wad of folded paper between microwave side and the cabinet its next to also does the trick, as long as you don't block any holes.

- Fan blades fouling housing

- adjust housing position slightly to clear the blades

- or slacken fan motor fixing screws and move it very slighly

- if all else fails, file the blade tips slightly on all blades equally. Sandpaper works.

Bulb failure

Some machines have a small unscrewable plate in the side to reach the bulb. With some you need to remove the whole outer cover - this can expose lethal high voltages (far above mains voltage).

Most microwaves take standard small bulbs designed for microwaves.

- I've often used small regular SES lamps instead, they just have shorter average life in a microwave.

Combination nukes use oven rated SES bulbs

- again one can substitude ordinary ones, but there's a slight risk of the bulb base coming away, making replacement difficult later, so its not best practice.

A minority of microwaves take less common bulb types. typically the bulb is screwed to the chassis and connected with push-on crimp terminals. Either get the right bulb from a repair shop, parts dealer or another nuke, or replace the bulbholder with a standard SES type.

Least common of all are machines that run 2x 110v bulbs in series. Either get the right type, or make life easier by replacing one with an SES holder & 240v bulb, and shorting the other one out.

If replacing a lightbulb with a non-original type, its good practice to mark the recommended wattage by the holder. 25w is most common.

Finally, if you never want a bulb to fail again you can convert the oven to use a mains LED bulb. Because it'll get hot in use at times, the LED needs to be derated by fitting a series capacitor to cut its light output to around half. If this is ignored, its likely to not last. LEDs aren't usable in combination cookers, they can't take that much heat.

Light too dim

A common issue, making it hard to see when the food's hot or boiling over.

- First clean both sides of the clear plastic or glass the light comes through, and clean the door.

Fixes that void any warranty include:

- increase bulb wattage a bit

- fit white card behind the bulb to reflect light into the cooking cavity

- In both cases, first check the bulb is surrounded by metalwork rather than plastic; these approaches are best avoided if its surrounded by plastic.

If replacing a lightbulb with a non-original type, its best to mark the recommended wattage by the holder.

Machine stops cooking after 15 minutes

Domestic microwaves are designed to cook for about 15 minutes on full power at most. Longer times are workable at lower power settings. The limitation is transformer temperature, to cook longer would take a much larger transformer.

Machines that run the fan when the door's open cool the transformer faster.

Canning spoilage

Microwaves aren't suitable for canning. The heat isn't even enough, and domestic microwaves can't apply power continuously for long enough (but they pretend to).

Oven keeps cooking with the door part open

I have seen an old oven still in use that continued cooking until the door was part way open. Unless you want to expose the inside of your head to half a kilowatt of cooking power, cut the mains lead off and scrap it, or donate it to a museum. Such ovens can't be made safe, adjusting the interlock correctly still leaves them dangerous.

Rust

Rust in the cooking cavity is harmless as long as there's still sound metal under it. If the rust patch shows any sign of coming apart when jabbed, its time to scrap the oven. (Welding is possible, but seldom worth it.) Rust patches can be made good with car rust remover & paint. Oiling the rust is a simple way to stop it spreading.

To minimise rusting, leave the door open or a bit after cooking.

Repairs

Transformer

These should be replaced with spares designed to fit the oven. But the cost isn't worthwhile in most cases.

The author has before transplanted unknown transformers from scrap ovens (it was once worth doing) with successes, using ovens with the same rated power input (ignore power output claims). Obviously all bets are off when doing this.

Magnetron

An understanding of the behaviour of microwave rf is advisable if replacing magnetrons. Key safety issues are anything but obvious if you don't have such knowledge.

Don't fit megnetrons not designed for the model of oven. Unlike transformers, slight differences in physical layout can cause microwave leakage & oven failure.

Diode

0819-4 Microwave HV diodes & resistor.bmp

The HV diode is usually plugged onto the HV capacitor, and easily replaced. It must be connected the right way round, or the oven won't cook.

Capacitor

Either use a part intended for the model, or another that's the right capacity, at least as high rated voltage, and physically fits.

Waveguide cover

The material's sold in sheets, cut it to fit. Mica sheets are fragile, don't bend them.

Magnetron cover

Mains fuse

With most electrical goods, the fuse is a safety element reducing risk of fire & shock. In a microwave oven the fuse performs an important extra role. Its a key part of the safety interlock system preventing users being microwaved. When an interlock error occurs the fuse must blow to prevent the user opening the oven door with the microwave source being on. This means using the correct rating and breaking capacity of the fuse is important.

When the fuse blows in a microwave, it often means there has been an interlock error. Such an occurrence often burns out the interlock resistor or sometimes an interlock switch is faulty. When this occurs, replacing the fuse will make the oven work again, but it won't really be safe. The next time an interlock error occurs the fuse won't blow, and you may expose your arm or head to intense microwave radiation.

If a fuse blows, test the interlock resistor and interlock switches before replacing it.

HV fuse

Some ovens have a high voltage 500mA fuse on the output of the main transformer to reduce fire risk. This can go open circuit. Don't use a mains voltage fuse to repalce it. Its normally housed in a short plastic tube moulded in 2 halves and snapped together.

Thermal cutout

Bimetal thermal cutouts cut power when transformer or magnetron overheat. These low cost parts can be had from many electronic component suppliers.

Replace with one with the same temp rating - each one in a machine has a different temp rating.

If for some reason you use a different temperature one, pick one with a bit lower temp rating. A lower temp rating reduces how long the oven can cook on full power. Fitting a higher temp cutout is likely to cause a major failure, microwave transformers are pushed pretty hard already.

Parts

New parts can be had from the usual sources, but are often an unnecessary spend, as free used parts are widely available from dead machines.

Scrap nukes provide fuses, bulbs, diodes, capacitors, motors, interlock resistors, and sometimes reusable waveguide covers. Other parts aren't usually worth reusing. The odds of a random turntable fitting a given nuke are fairly low.

Fault prevention

- Keep the waveguide cover or magnetron cover clean.

- Don't get hammered and put the noodles on for 30 minutes. Its not clever.

Recycling

- door glass makes a chopping board

- turntable motor makes a megger

- transformers can be used to make welders, but little else