Cables

This article describes the main characteristics of most of the different types of cable currently used in domestic installations.

The following have their own articles:

- Mains flex

- Cable and flex for Low Voltage Wiring

- Historic Mains Cables

Cable types

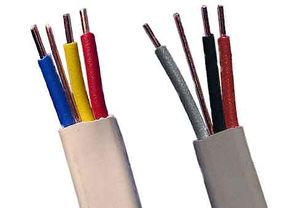

T&E

Twin & Earth cable. This is the most common cable used for domestic wiring today.

- aka FTE (flat twin & earth)

- Live and neutral are individually insulated, and the Circuit Protective Conductor (CPC) aka earth is bare

- An overall sheath of grey PVC (BS 6004), or white for low smoke compound (BS 7211)

- Not suitable for unprotected use outside (outer sheath materials are vulnerable to attack by UV; alkyd paint is enough to protect it from UV)

- 1mm² 1.5mm² & 2.5mm² have solid (non-stranded) conductors

- 4mm², 6mm², 10mm², 16mm² and higher have stranded conductors

- 1.5mm² & 2.5mm² stranded T&E is available and legal to use but it is very unlikely to be seen in a domestic situation

- Irish T&E is requierd to have fully insulated full size earth conductor

Variants of T&E

3&E

Three core and earth. Has three insulated conductors and a bare earth conductor.

In all other respects as T&E above. Typically used for two way lighting circuits, or other applications needing a permanent and switched live supply as well as neutral (e.g. feeding light switch activated extractor fans).

Also available in both PVC (BS 6004) and low smoke (BS 7211) versions.

Single & earth

- Like T&E but with no neutral conductor.

- Not popular

- Supplier

See circuit diagram here.

Twin live & earth

As T&E, but 2 live coloured conductors. Typically used for the drop wire to a light switch where one conductor will carry a permanent live, and the other the switched live.

- Not popular

- T&E with added sleeves at the ends has the advantage of showing which conductor is which, and of usually already being on hand

LSF / LSH / LSZH

Low Smoke & Fume, Low Smoke & Halogen, or Low Smoke Zero Halogen. A cable with insulation and /or sheathing designed to minimise the amount of toxic fumes released when burnt. Low smoke versions of commonly available PVC cables are readily available, e.g. BS 7211 for the PVC-sheathed BS 6004, and BS 6724 for the PVC-sheathed BS 5467.

- Available in pretty purple

Singles

- Insulated single conductors (larger sizes are stranded as per T&E table above)

- Standard cable for use in conduit

- Typically used in domestic work only for main & equipotential bonding

- Also available in both PVC (BS 6004) and low smoke (BS 7211) versions.

Imperial T&E

- Coarsely stranded T&E in imperial sizes, with a few possible insulation types

- See Historic Mains Cables

Tails

Very heavy gauge singles with two layers of insulation. Typically used for connections between electricity incomer, meter, and consumer units. Common sizes include 16, 25, and 35 mm². Commonly available from distributors as colour coded lengths in pairs. Older tails may only have a single layer of insulation.

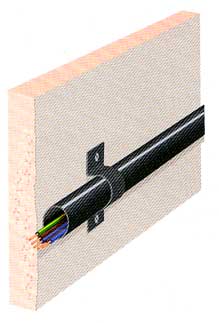

Armoured Cable / Steel Wire Armoured

Steel wire armoured (SWA) cable is a robust cable frequently used for exterior wiring, where it can be buried directly in the soil, or suspended from a catenary wire. It consists of a number of individually insulated conductors covered next with a flexible bedding, then by a spiral screen of galvanised steel wires, and finally by a tough outer sheath. The insulating materials used typically being PVC or XLPE thermosetting plastic (the latter having a higher temperature rating, hence allowing the cable to carry a larger maximum current for a given conductor size). PVC Sheathed version if to BS 6346, XLPE-sheathed version is to BS 5467, and the low smoke version is to BS 6724.

- For outdoor & garden use.

- Available in 2, 3, 4, & 5 core versions.

- Must be terminated using the correct glands.

- May use the steel wire armour for the circuit earth / CPC in place of, or in addition to a core.

- How to terminate SWA

- Discussion on terminating SWA

Cable Sizes & current carrying capacity (stranded copper conductors) BS 5467 XLPE Insulation

| Conductor area (mm²) | Current carrying capacity (A) for cables "clipped direct" |

Overall diameter (mm) | |||||

|---|---|---|---|---|---|---|---|

| 2 core 70°C PVC |

3 or 4 core 70°C PVC |

2 core 90°C XLPE |

3 or 4 core 90°C XLPE |

2 core | 3 core | 4 core | |

| 1.5 | 21 | 18 | 27 | 23 | 12.1 | 12.8 | 13.3 |

| 2.5 | 28 | 25 | 36 | 31 | 13.6 | 14.1 | 15.0 |

| 4 | 38 | 33 | 49 | 42 | 14.7 | 15.3 | 16.4 |

| 6 | 49 | 42 | 62 | 53 | 15.9 | 16.6 | 18.7 |

| 10 | 67 | 58 | 85 | 73 | 18.0 | 19.5 | 21.1 |

| 16 | 89 | 77 | 110 | 94 | 20.4 | 21.6 | 23.4 |

MICC

Mineral Insulated Copper Clad Cable. Renowned for having good fire resistance and also a smaller conductor cross section for a given current carrying capacity than other cable types

- aka pyro (from makers name Pyrotenax)

- Copper tube sheath with powdered magnesium oxide insulation

- Fireproof

- Rigid

- Occasionally seen in domestic premises, mainly in blocks of flats

- Widely used for fire alarm systems in commerce

- Unterminated ends prone to absorbing moisture from the air

- Special cable terminations required

- Ideal for flammability risk areas, eg traversing a thatched roof.

- Picture shows 1.5 mm² MICC with outer diameter 7.2 mm

MICC is one of the toughest of cables because:

- its metal cased

- it handles very high temperatures

- it still works even if you hammer it quite flat - the conductors and mineral insulation all compress in the same proportion, and you have to go a long way before it shorts out

Very thorough Guide to MICC cables

NYY-J or Hi Tuff

A PVC cable that is more robust than standard PVC sheathed cables and is suitable for general power, control and fixed wiring uses. An alternative to SWA for outdoor applications when direct burial of the cable is not required.

- Temporary wiring on open sites.

- Lighter and more manageable than steel wire armoured cables and requires only nylon glands to install - factors which contribute to speed of installation and cost savings.

- Provided there is no specific requirement for additional metal protection such as steel wire armouring, it meets the demands of the most arduous installation conditions.

- Will not ignite under extreme applied heat.

- NYY-O has no earth conductor.

FP 200 and other Soft Skin Fire Alarm Cables

Introduced as an alternative to MICC cable, but not as robust (the sheathing can burn away but circuit integrity is maintained).

- Silicone compound insulation

- Overlapping internal metal screen and drain wire (CPC)

- Low smoke sheathing material

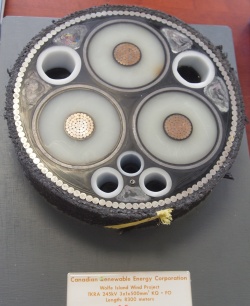

Concentric cables

Neutral and earth conductors are arranged distributed around the central live conductors. Mainly used for incomers.

T&E data

T&E current carrying capacity

Note The current carrying capacity values given for the various cable sizes above are only correct for the fixing methods listed. They are also only correct for a single cable not in close proximity to any other cables. For all other installation methods not covered above, the values stated will be incorrect. To find the correct rating in these circumstances the quoted current carrying capacity listed in columns C (i.e. method 1) will need to be "de-rated". This means that correction factors need to be applied to the current carrying capacity in order to factor out these environmental effects that otherwise could result in cable overheating (and hence overloading) if ignored.

In addition to the fixing method, there are other correction factors that will effect the rating:

- Ambient Temperature

- Covering in thermal insulation

- Grouping cables together

- Use of semi enclosed (rewireable) fuses

- Encapsulation in conduit or trunking

For more details on how to do these calculations, see the Calculating A Cable Size article. Full details of the de-rating factors and more detailed version of current carrying capacity table, see table 4D1A in appendix 6 of the On Site Guide.

Voltage Drop

Any design must ensure the maximum voltage drop allowed between source and point of use is not exceeded when at full load. In the 16th edition this is 4% of the nominal supply voltage (about 9.2V at 230V AC). The 17th edition (in force from 1 July 2008) limits this to:

- 3% for lighting

- 5% drop for other loads

- (but 6% and 8% respectively are permitted for private supplies)

| Conductor CSA (mm²) | PVC (max 70° C)

Voltage drop mV/A/m |

XLPE (max 90° C)

Voltage drop mV/A/m |

|---|---|---|

| 1.0 | 44 | 46 |

| 1.5 | 29 | 31 |

| 2.5 | 18 | 19 |

| 4.0 | 11 | 12 |

| 6 | 7.3 | 7.9 |

| 10 | 4.4 | 4.7 |

| 16 | 2.8 | 2.9 |

These figures are presented for SWA cable here. The values quoted will usually also be correct for other copper cable types. Figures differ for cables with higher operating temp limits, such as MICC. The length figure above is per length of cable, not per each conductor.

These figures assume that the cable is operating at or near its maximum operating temperature. In designs where the maximum current load is significantly less that the capacity of the cable then these figures will be somewhat pessimistic. For these circumstance, it would be more appropriate to calculate voltage drops based on table 9A of the On Site Guide.

Calculation Examples (PVC SWA): 1) 20m of 4mm², maximum load of 30A would drop 20 x 0.011 x 30 = 6.6V 2) 40m of 6mm², maximum load of 45A would drop 40 x 0.0073 x 45 = 13.14V 3) 10m of 1.5mm², maximum load of 16A would drop 10 x 0.029 x 16 = 4.64V (1) and (3) are adequately specified with respect to voltage drop. However (2) is out of spec and a larger cable will need to be selected, even though the current handling capacity of the 6mm² cable has not been exceeded. Upgrading to 10mm², gives a result of 40 x 0.0044 x 45 = 7.92V which is acceptable. It initially appears that this still only leaves just over 1V of remaining drop available for any following wiring, however since we will not be operating the larger cable anywhere near its maximum temperature, the situation is actually less tight than the calculation suggests.

Cable Sizes

Metric Cables

| Conductor area / CPC area (mm²) |

Current carrying capacity (A) for various reference methods (see table below) |

Conductor dia (mm) |

Outer PVC size (h x w)(mm) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | 100 | 101 | 102 | 103 | |||

| 1 / 1 | 11.5 | 13 | 16 | 13 | 10.5 | 13 | 8 | 1 x 1.13 | 4.5 x 8.2 |

| 1.5 / 1 | 14.5 | 16.5 | 20 | 16 | 13 | 16 | 10 | 1 x 1.38 | 4.7 x 8.2 |

| 2.5 / 1.5 | 20 | 23 | 27 | 21 | 17 | 21 | 13.5 | 1 x 1.78 | 5.3 x 9.9 |

| 4 / 1.5 | 26 | 30 | 37 | 27 | 22 | 27 | 17.5 | 7 x 0.85 | 6.1 x 11.4 |

| 6 / 2.5 | 32 | 38 | 47 | 34 | 27 | 35 | 23.5 | 7 x 1.04 | 6.8 x 13.1 |

| 10 / 4 | 44 | 52 | 64 | 45 | 36 | 47 | 32 | 7 x 1.35 | 8.4 x 16.8 |

| 16 / 6 | 57 | 69 | 85 | 57 | 46 | 63 | 42.5 | 7x 1.71 | 9.6 x 19.5 |

Note: Outer cable sizes are guideline figures and can vary for different brands of cable of the same conductor size.

For minimum bend radii of T&E cables see this table

Imperial Cables

You will frequently find old twin and twin and earth cables in imperial sizes. The specifications for these are as follows (note the CPC size is not specified)

| Conductor size | Current carrying capacity (A) for various reference methods (see table below) |

Conductor dia (mm) |

Outer PVC size (h x w)(mm) | ||

|---|---|---|---|---|---|

| Nominal Overall CSA (inch²) |

No. & diameter (inch) of strands |

A | C | ||

| 0.0015 | 1/0.044 | 10 | 12 | 0.97 | TBD |

| 0.002 | 3/0.029 | 12 | 15 | 1.29 | TBD |

| 0.003 | 3/0.036 | 16 | 19 | 1.94 | TBD |

| 0.0045 | 7/0.029 | 19 | 23 | 2.90 | TBD |

| 0.007 | 7/0.036 | 26 | 31 | 4.52 | TBD |

| 0.01 | 7/0.044 | 31 | 37 | 6.45 | TBD |

| 0.0145 | 7/0.052 | 40 | 46 | 9.35 | TBD |

| 0.0225 | 7/0.064 | 52 | 61 | 14.52 | TBD |

Determining Size

The quickest way to measure conductor size is to use a micrometer. If you don't have one, cut off a known length of copper and weigh. Copper density = 8.96 grams per cc.

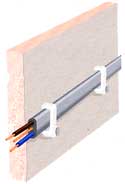

Installation Methods

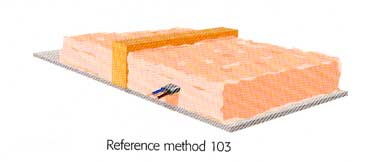

The current carrying capacity of any cable is dictated by its maximum conductor temperature, and this in turn will be affected by its ability to dissipate heat. The way it is installed can have a significant effect on this ability. The following table explains the methods cited above. The number of installation methods described in Table 4A2 (previously 4A1) has risen from 20 to 50-odd. Although this may appear to make things more complicated, the appendix now embraces installation methods that are used but which were not previously accounted for, including installation methods in building voids, direct in ground, in ducts in the ground, and flat twin and earth cables in thermal insulation. It is impractical to calculate and publish current ratings for every installation method, since many would result in the same current rating. Therefore a suitable (limited) number of current ratings have been calculated which cover all of the installations stated in the Wiring Regulations, and are called reference methods. All the individually numbered installation methods have a lettered reference method stated against them in Table 4A2, except for flat twin and earth cables which have reference method numbers 100 to 103. There are seven alphabetically lettered reference methods, that is A to G (the most common A to C are shown in the tables above).

| BS7671 17th Editon Reference Method |

Example of installation method | BS7671 16th Edtn Reference method |

BS7671 17th Edtn Installation method |

|---|---|---|---|

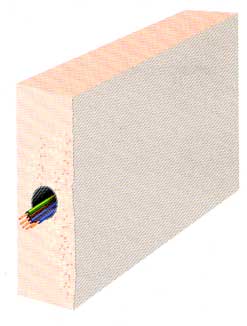

| A | in conduit in an insulated wall with the conduit close to or touching the inner skin | methods 4 & 6 | methods 1 & 2 |

| B | enclosed in conduit or trunking on or in a wall    |

method 3 | methods 4 & 5 |

| C | clipped direct, or sheathed cables embedded directly in masonry, brickwork, concrete, plaster or the like (other than thermally insulating materials)

|

method 1 | method 20 |

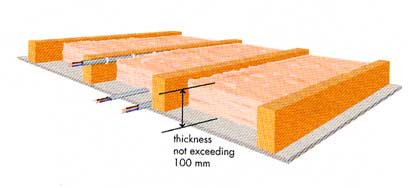

| 100 | above a plasterboard ceiling covered by thermal insulation, insulation thickness <100 mm  |

15 | method 100 |

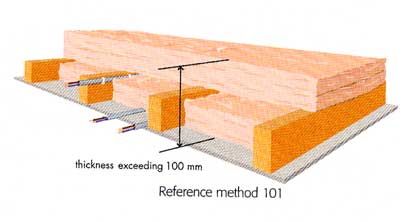

| 101 | as above but with insulation thickness >100 mm  |

15 | method 101 |

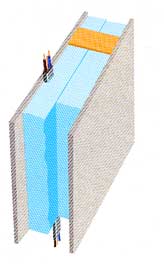

| 102 | in a stud wall with thermal insulation with the cable touching the inner wall surface  |

15 | method 102 |

| 103 | in a stud wall with thermal insulation with the cable NOT touching the inner wall surface  |

15 | method 103 |

- Methods 100, 101 and 102 require the cable to be in contact with the plasterboard ceiling, wall or joist

- Ratings (BS 7671 Table 4D5A (16th), or Table 4D5 (17th)) apply for ambient temperature of 30 deg.C and a maximum conductor temperature of 70 deg.C

- All the usual derating factors apply (see below and appendix 4 of BS 7671 or appendix 6 of the OSG).

- Current ratings are continuous.

- Reference methods not included in the table are. Reference method D - Direct in the ground or in ducting in the ground. Reference method E - Multicore cables in free air or on perforated trays. Reference method F - Single-core cable touching in free air or on perforated trays. Reference method G - Single-core cable spaced in free air or on perforated trays.

Typical T&E Cable Applications

| Cable Size (mm²) | Typical Applications |

|---|---|

| 1.0 | lighting circuits |

| 1.5 | high power lighting circuits, 16A Radial power circuits |

| 2.5 | 32A Ring final circuits, 20A Radial circuits |

| 4.0 | 32A Radial circuits, Cooker circuits, low power electric showers |

| 6.0 | Small Sub mains, Radial circuits for showers, high power cookers, and other high power devices |

| 10.0 | Sub Mains, Radial circuits for high power showers, cookers, and other very high power devices |

| 16.0 | Sub Mains |

Conductor Colours and Harmonisation

Historically the UK used its own set of colour codes for fixed and flexible wiring. In the early 1970s the colours used for flexible wiring were harmonised across Europe, however the colours for fixed wiring remained unchanged until recently. In March 2004 the fixed wiring colours were also harmonised.

During a transition period that began on 31st of March 2004 and ended on the 31st March 2006, use of either colour scheme was acceptable. Now only the harmonised colours may be used.

The result is that it is now possible to encounter installations that use both colour schemes, and hence great care must be taken to ensure conductors are correctly identified when carrying out any work.

Conductor Colour Coding (single phase T&E)

| Conductor | Old UK Colour | Harmonised Colour |

|---|---|---|

| Live (Phase) | Red | Brown |

| Neutral | Black | Blue |

| Earth or CPC | Green / Yellow Stripe | Green / Yellow Stripe |

| Conductor | Old UK Colour | Harmonised Colour | 2 Core (T&E or SWA) |

3 Core (3&E or SWA) |

4 Core (SWA) |

5 Core (SWA) |

|---|---|---|---|---|---|---|

| Live 1 | Red | Brown | X | X | X | X |

| Live 2 | Yellow | Black | X | X | X | |

| Live 3 | Blue | Grey | X | X | X | |

| Neutral | Black | Blue | X | X | X | |

| Earth (CPC) | Green / Yellow Stripe | Green / Yellow Stripe | X[1] | [1][2] | [2] | X |

Notes

- Earth wire in cable will be a bare conductor and will need green/yellow sleeving to be applied at point of termination.

- Earth wires are present in T&E or 3&E cables. Other cable types such as SWA or MICC will still need to be earthed, however this will be carried using the cable armour / screen.

There is an IEE leaflet explaining these changes. That is available here

Installations that are wired using cables to both colour schemes should carry a warning sticker (see example) on or near the consumer unit that states:

| CAUTION

This installation has wiring colours to two versions of BS7671. Great care should be taken before undertaking extension, alteration or repair that all conductors are correctly identified. |

Cables in contact with polystyrene

Do not let electrical cables come into contact with polystyrene. It slowly leaches the plasticiser out of the PVC, so that it becomes stiff and brittle. Sometimes it looks like the PVC has melted and run a little.

See Also

- Calculating A Cable Size

- Flex

- Understanding harmonised cable codes

- Low Voltage Wiring

- Historic Mains Cables

- Wiki Contents

- Wiki Subject Categories

- Cable Sizes

- Wiring colour codes

- Cable Resistances

- Cable capacity & Vdrop table

- Choosing cooker cable size