Saw

Hand saws

Hacksaw

- 2 types:

- Junior hacksaw, 6" blades

- Bigger one, 12" blades & other sizes

- Ok for metal & plastic

- A high percentage seem to have blunt blades. If the central blade area is much duller than the ends, time for a new blade.

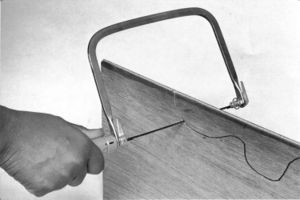

Mitre Saw (manual)

- Wood is clamped to the base

- Frame guides saw blade, keeping it at the chosen angle

- Small captive handsaw of some type cuts the timber

- Quite different to the electric mitre saw

Jack Saw

- General purpose construction saw

- Coarse teeth

- Cuts timber, aerated concrete, rigid insulation etc

Toolbox Saw

- Shorter version of jack saw

- Fits in toolboxes

Floorboard Saw

- Has additional teeth on the top side in an arc near the end

- Can saw into floorboards in situ

- The handsaw of choice for cutting into flat surfaces

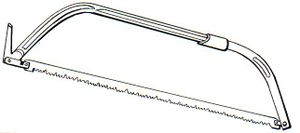

Bow Saw

- For sawing trees

- The coarse peg teeth usually used cut on both strokes

- 2 blade types for dry wood & green wood.

- Come in various sizes

- Spear & Jackson are well regarded

- To counter sap making the blade sticky, oil blade before use, and wash in water when it gets mucky

- Bowsaw review

Backsaw

- Saws with reinforced back, such as tenon saw

- Rigid blade for maintaining cut accuracy

- Limited cut depth

Coping Saw

Crosscut Saw

- Saw optimised for cutting across the grain

Pullsaw

- Any saw that cuts on the pull stroke

- Blade thinner than pushsaws

- Less effort for given progress than pushsaws

- Japanese saws are generally pullsaws, Europeans are generally pushsaws

- See Japanese saws

Fretsaw

- Saws with very thin blades used for cutting intricate curves

- Manual fretsaw has a very deep frame & short blade

- Blades are extra fine and a bit fragile

- Originally used for cutting latticework

- Metal cutting blades also available (much finer teeth)

- Spiral blades available, which can cut in any direction but have a wider kerf

- Electric scroll saws are often called fretsaws, and use the same blade type.

Japanese Saws

- Several types are useful for DIY

- Japanese saws normally cut on the pull stroke, enabling use of thinner flexible blades. Less kerf means less physical work to achieve a given cut.

- Tend to cost much more than western style saws

Azebiki

- Japanese pullsaw with teeth on an outward curve

- Plunge cuts

- 2 different TPI blades

- Good for cutting floorboards

Gents Saw

Keyhole Saw

- Very narrow blade for tight spaces

Tenon Saw

Two-man saw

- aka pit saw

- Long slightly curved blade with a handle on each end

- Double the sawing power

- Very long stroke

- About the only DIYer accessible saw that can cut whole mature trees into lengths

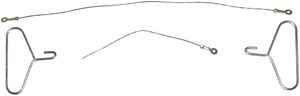

Wire saw

- Flexible saw wire with a handle on each end

- Mostly used for veterinary uses (bones, horns)

- Exceptionally good access properties for difficult cuts, can thread through and round things

- Not expensive

- Coils into a tiny size, one could carry 10 in a pocket easily

- Not stocked by many DIY tool suppliers

- A popular tool in survival kits due to tiny size

- Note the silverline one is not very flexible, and breaks if coiled.

Tile saw

- an abrasive saw for all tile types

- The abrasive rod cuts in any direction

- good for small curved cuts

- the one shown has a drill bit built into one end

Pruning saw

- For cutting small trees and limbs

- Frameless

- Gives better access than a bowsaw

Long reach pruning saw

- Pruning saw blade on a pole

- Handle often telescopic for easy storage

Homemade pruning saw

- Can be made with a blade from any coarse toothed construction site type saw and some 1 x 3/4

- Longer handles if desired

- Less effort to use due to narrower kerf & longer blade

- Larger blade less able to get into tight spaces

- Lower cost

- Quick to make

Power Saws

There are a number of different types of power saws available, each suitable for different types of job;

Jigsaw

- Low cutting speed

- Can cut curves

- Steer by rotating the saw, never push sideways

- Quality varies greatly

- Cheap & midrange jigsaws:

- Performance generally anything from patchy to dire

- Blades wander & bend badly

- Cost of ruined wood over the lifetime of a cheap or midrange jigsaw soon exceeds the cost of a better saw

- Not possible to cut a straight line using a guide fence, as they need regular direction correction

- Good jigsaws:

- The blade is constrained with rollers

- Can cut straight lines

- Much less prone to blade bending, but not immune

- Jigsaw review

Jigsaw blades

- Many types of blade available:

- Coarse, medium, fine

- Blades for wood, metal, plastic, leather, paper products

- Flush cutting offset blade

- Knife

- Grit

- Varying teeth pitch

Blade quality also varies greatly. Cheapo blades can wander and bend badly, when a decent brand of blade in the same machine cuts fine. Coarse TPI blades are less prone to wander.

Circular saw

- Main article Circular saw

- Fast cutting

- Cuts straight lines only

- Good general purpose DIY saw

- Riving knife reduces risk of kickback - some saws lack one

- Blades with high number of teeth can produce very smooth cuts

- Normally supplied with a guide fence

- Depth of cut and angle can be preset

- Max possible cutting depth is less with angled cuts

- Not safe to use for felling trees. As wind rocks tree, it clamps up on the sawblade, throwing the saw back at the user

- Hand held, bench type and cordless circular saws are all used for DIY

Cordless circular saw

The lower power of these often makes it possible to hold these saws safely against kickback. When this is so, they can also be used for plunge cuts and tree cuts.

Mitre Saw

- Compound mitre saws' blades can swivel in 2 axes for compound angle cuts.

- Fast cutting

- Fairly small max cut width

- Hence mostly used for cross cutting

- Circular saw blade

- Cutting head swivels to cut at various angles

- Cutting head tilts to give cuts angled in 2 axes

- The quality of these machines varies widely

- Plastic bases found on budget machines bend slightly under force, misaligning cuts.

- On poor quality machines the saw head may be subject to some unwanted movement

- Cut width can be roughly doubled if the workpiece is turned over to complete the cut from the other side. The result is pretty good if care is taken to get good alignment for the second half of the cut, but not perfect.

- Built in laser makes aligment of timber much quicker than running an eye across the blade. Some lasers are mains powered, some require batteries. The beam position does need correct adjustment

- See Mitre saw review

Sliding Mitre saw

- Mitre saw with cutting head that slides to cut wider timber

- Enables longer cuts to be made in larger timber

- Sliders are more prone to inaccuracy and free play, so a more expensive machine is required for any given level of accuracy

Flipsaw

- Mitre saw with a sawhead that flips over to give either a mitre saw or benchsaw

Cutoff Saw

- Look somewhat like mitre saws, but with no angle adjustments

- Cuts at precisely 90 degrees

- Workpiece clamp included

- Abrasive grit blade usually used

- Primarily used on metalwork

Scroll Saw

- Very thin blade can be easily fed through a hole for islanded cuts

- Vibrating blade only moves a very small amount, and can be touched without injury

- The only type of power saw safe for young kids

- Effectively a modern version of the fretsaw

- Make a Heart box

Spiral saw

- eg Rotozip

- Can plunge into solid materials then drill in any direction

- Can't withstand much sideways force

- Limited uses due to poor performance with a lot of uses

- OK for very soft materials

- Die Grinders can use the 1/8" spiral saw blades, but such thin blades are very weak

- Spiral saws taking 1/8" blades also take die grinder accessories - check speed ratings though

Table saw

- Circular blade

- Fast feed rate

- Plastic or wood pushers are used to keep hands away from blade

- Old table saws lack guarding

Sawstop table saws

- A safety system that detects touching of the blade, and destructively stops the blade to minimise injury

- Not cheap

- Safety system must be turned off on green wood, in the rain etc to prevent it activating

- http://en.wikipedia.org/wiki/SawStop

Bandsaw

- Main article: Bandsaw

- Uses a blade consisting of a continuous loop of spring steel, with cutting teeth on one edge. This rotates around two aligned wheels (one of them driven), and passes vertically through a cutting table.

- Coarse, fine and omnidirectional blades available

- A typical DIY bandsaw blade of 12mm width allows straight and curved cuts down to about 150mm radius to be comfortably made. Narrower blades allow much tighter curves to be cut

- A few settings need to be correct to achieve a good clean straight cut

- Bandsaws also exist in metal cutting and food cutting versions.

Tile saw

- Small table saw with diamond grit circular tile blade

- Water cooled blade

- Makes very clean cuts in tiles, concrete etc

- Can cut small strips of tile neatly too

- Replacing the blade with a wood cutting one enables use as a tablesaw, but blade height above the bench is low. Some saws have enough room for a slightly bigger timber blade

- Main article: Tile cutter

Reciprocating saw

- Powered version of jack saw or hacksaw

Chainsaw

- Very fast rough cutting

- Good for felling trees, cutting up trunks etc

- Used for chainsaw art too, quick carving of tree stumps etc into fancy shapes

- Relatively high risk saw

- Protective clothing is wise

- Basic training is wise

- Correct type of oil important

- Blade should not contact soil

- Tip must not touch workpiece, or the tool throws at the user

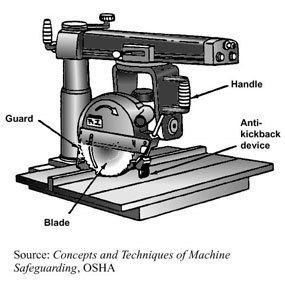

Radial arm saw

Another type of sliding circular saw

Holesaw

- Coarse tooth holesaws cut wood & plastic, and some cut metals

- Abrasive core drills are used on masonry

- One piece cup shaped blade holesaws are durable

- Bit of flexible sawblade clips into metal base type holesaws are very weak and must be used with care

- See main article Holesaw

Dado saw set

- Dado saw heads are assemblies that cut slots using a table saw

- The simpler type is a pair of wobble washers that result in the blade being mounted slightly on the wonk

- The other type uses 2 circular blades with a chip remover between them

- The latter increase blade inertia and spin down times beyond permitted limits, and are thus illegal in the UK. They're widely used in the US.

Concepts

- TPI

- number of teeth per inch. For a bandsaw and handsaws, 6tpi is for fast rough cutting, 14tpi gives a fine finish in wood, 24tpi cuts plastics & most metals

- Number of teeth

- For circular saws, 10 teeth give a rough cut, 24 a fine cut, 40 a superfine cut eg for cabinet work

- Kerf

- The width of the sawn slot

- Tooth breakage

- Once one tooth breaks, more soon follow. The main way to avoid it is to ensure the ratio of tooth spacing to workpiece is such that there are always at least 2 teeth in contact with workpiece.

Tooth Materials

- Hardpoint

- Hardened steel teeth. Low cost sawblade type. The teeth wear, requiring regular blade relacement. Teeth can occasionally break off too.

- TCT

- Tungsten Carbide Tipped. Highly durable TC tips are brazed to the blade. The result is a blade that cuts much faster, and cuts harder materials with ease. Blades last a long time before dulling.

Early TC saws in the 1940s suffered from the tips shattering easily in use. Todays TC saws avoid this by using tips made from a matrix of TC grit set in a relatively soft metal. This gives the toughness of TC without the tendency to shatter.

Swapping tooth types

Don't fit a non-TC blade into a power saw designed for TCT blades. The steel teeth will not be able to cope with the workload, and accidents can result. TCT blades can be used in old saws designed for steel teeth, and stay sharp much longer.

Materials

Wood

Coarse blades give fast cutting but a rough result. Finer toothed blades give a cleaner result but slower progress. The subject of wood saw tooth geometry is a good deal more complex than just this, and covers questions of tooth spacing, tooth cutting material, tooth geometry and other matters.

Laminates

Laminates and melamine in particular tends to break along the sawn line, giving a very poor edge. Methods used to combat this:

- Place scrap sheet material on top of the workpiece, with the valued laminate face layer uppermost

- Place the workpiece face down, sat on scrap material

- Cut it 1/4" oversize and plane down, holding the plane at an angle to prevent any lifting of the melamine

- Some saws cut cleanly enough to simply place the laminate layer so the sawblade goes into that side of the material. But a lot of saws don't give a clean cut this way. Maximise the odds by taking the cut very gently.

Less than perfect methods include:

- Score with a stanley knife before cutting

- Some people stick tape on the workpiece before cutting, I've never had a good result that way though

- Saw very shallow through only the top laminate layer, then saw the board again full depth

Steel

Steel can be cut by a fine toothed saw, or other methods such as nibbler or grinder. It can also be melted by a welder or cutting torch.

Hardpoint saws wear quite rapidly when cutting steel.

Non-ferrous metals

These can be cut by a fine toothed hand saw or a fine tooth power saw. Mitre saws can use coarse teeth, but go easy with the pressure.

Plastics

For hand cutting a fine toothed blade is needed. Power saws may also use a coarse blade if the pressure on the workpiece is kept gentle, and the plastic is strong enough to not bend much during cutting.

Thin unsupported plastics tend to bend into a coarse blade and get broken. Options are to use a fine tooth blade, or to turn a coarse TCT blade round so it runs backwards.

Power sawing plastic can result in the blade heating up and this affecting the cut, but this isn't likely to happen with just sawing one small item. Some power saws have a lower speed setting to reduce this issue.

Tree Felling

Power saws:

- The chainsaw is the undisputed king of tree felling, but there are other options too

- Reciprocating saws do the job, but are slower

- Circular saws are not safe for general tree felling. There are specific circumstances in which its possible to make their use safe, but using them regardless is a recipe for an accident

Hand:

- A bowsaw is best for garden trees that aren't too big for it. The tooth geometry cuts fast

- 2 man saw is the only handsaw option for large trees

- Pruning saws can do small limbs, but making your own with a bigger blade gives a quicker result. The 8' or so handle can be handy

- Smaller non-felling saws such as basic construction site handsaws (jacksaws) also work upto their size limits, but are quite a bit slower cutting due to different tooth geometry

- Axe

Sawmill

Portable sawmills can be bought, hired or home made for processing trees.

Bandsaws are cheaper to make than other types, and upping the size doesn't add costs as much as other types, thus the end product generally has a larger cut depth. Bandsaws have the narrowest kerf, wasting less timber. The blades can be changed to vary the tradeoff of cut speed versus cut quality. Sawbands however don't always last, and the steel teeth need repeated sharpening.

Circular saw based mills were once more popular. Large discs are expensive to replace if TCT, and require more sharpening if steel point. They have limited depth of cut and wider kerf.

Chainsaw based mills are much faster than the other types, but have very wide kerf. The wide kerf makes produding thin timber pieces very wasteful. They're much safer than hand held chainsaws.

Alaskan mills are an especially simple type of mill, usually made with a chainsaw.

Instructions for making all types can be found on youtube.

Reviews

To Do

Plywood saw Rip saw Saw set Pics