Weather compensation

What is weather compensation?

Weather compensation is designed to automatically adjust the temperature of the water fed to the radiators by your boiler in response to the current weather. This allows the boiler to run at a lower power when the weather is milder, but to automatically increase output when it is colder.

The advantages of weather compensation:

- Higher boiler efficiency - a modern condensing boiler can recover more energy from the flue gases with lower water return temperatures. This leads to lower fuel bills.

- Better comfort with fewer temperature overshoots.

- Less cycling of the boiler, less thermal stress, and wear and tear on the system components, so longer system life.

- Less system noise, cooler water results in less thermal expansion - so less clicking and clanking of pipework and radiators.

How does it work?

At its most basic level, weather compensation needs two capabilities: a way to sense the external temperature, and a way to control the temperature of the water flowing round the radiators.

An external thermometer (usually placed high up on an north facing outside wall, away from direct sunlight), allows the system to sense the external temperature. Knowing the temperature the compensation system can increase the flow temperature on colder days, and reduce it on milder ones.

Modern boilers with electronic controls have facilities to modulate their output power to control the temperature of the water they produce. Older fixed output boilers can use external electrically controlled blending valves, to mix some cooler return water with the hot flow water to control the temperature of the flow water.

Weather compensation can also be used with thermal stores and heat bank style systems where the boiler does not directly heat the water circulated through the radiators or under floor heating. This is typically achived with controllable blending valves, or variable speed pumps.

Tuning the system

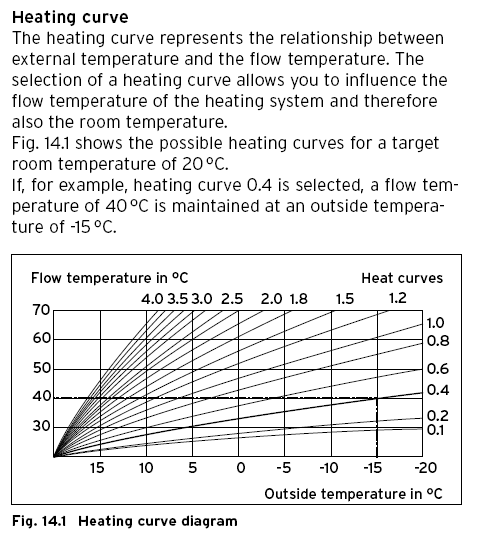

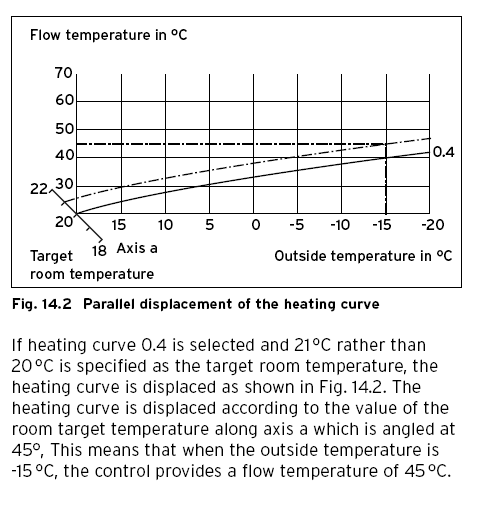

The big unaccounted for variable is of course the weather and the thermal performance of the building. Most compensation systems just work from an external temperature reading (an ideal one might also include wind speed and humidity). The temperature can then be mapped to a target flow temperature using a transfer function or lookup table that relates the external temperature to the required flow temperature.

The installer of the system will need to choose the correct mapping based on how quickly the property looses heat, and how easy it is to get back up to the desired temperature. Modern well insulated and relatively air tight properties should loose heat less quickly than older draughty solid wall properties with little or no insulation.

A heating system designed with large radiators will likely be able to adequately heat a place at a lower flow temperature than one with smaller radiators.

So in mild weather, relatively low flow temperatures around 40°C are likely to take the chill off, and keep the place feeling comfortable. In a well insulated place with large radiators, it might be possible to adequately heat a well insulated place all year round with the flow temperature never needing to exceed 50°C. A more "difficult" property might need flow temperatures nearer 80°C in the depths of winter.

What about the room thermostat?

Weather compensation systems in very large buildings with very high thermal masses (lots of thick brick or masonry walls), may not even bother to include an internal thermostat, since the amount of time required to change the internal temperature is measured in days rather than hours. So the best that can often be achieved is to slave the heat input to the building to match the anticipated rate of loss due to the weather, and hope that the internal temperature will stay roughly constant in spite of the weather.

Most domestic systems will still have at least one internal room thermostat, and quite likely thermostatically controlled radiator valves as well. With most heating systems, the thermostat is only able to supply a "call for heat" signal to the system - basically "it's not warm enough, please turn on", or "It is warm enough, turn off".

Load compensation

Some of the more sophisticated control systems are able to communicate the actual internal temperature to the boiler, and also the currently selected target temperature. In these cases a weather compensating system can add a little more finesse to the control of the flow temperature from the boiler; nudging the flow temperature up in cases where the difference between the target temperature and actual temperature is large. This will hopefully allow cold place to heat up more quickly that it otherwise would. This is sometimes called "load compensation".

Retrofitting

Some boiler ranges have support for weather compensation included, and just need the addition of the right controls.

Adding it to systems without built in support can be done, but there are a few points to lookout for:

- There may be no way to electrically alter the flow temperature of the boiler externally, so you would need to use the blending valve approach described above to control the flow temperature.

- If your boiler is used to heat a hot water cylinder (i.e. not a "combi" boiler), then you need to be able to identify which demand is currently firing the boiler, since you don't want the weather compensated reduced temperature flow when reheating the cylinder. Again boilers with the capability baked in understand this and support split temperature operation. If rolling your own then you will need to disable weather compensation for cylinder reheats.

- Another implication is that the system can't be used to heat the radiators and a hot water cylinder at the same time, since this would force the very hot water required for the cylinder reheat round the rads as well. So zoned heating systems may need additional logic to prevent operation of hot water and radiators at the same time.

Split temperature operation

Most external temperature sensors use a Negative Temperature Coefficient (NTC) thermistor to "read" the temperature. These change their electrical resistance such that it falls as they get warmer.

The easiest way to implement split temperature operation on systems that don't support it directly, is to use a relay to switch additional resistance into the path of the external temperature sensor. This will make the weather compensator think it is a very very cold day, and ramp the flow temperature right up to compensate.