Sheet material

Sheet Woods

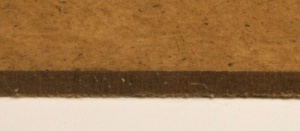

Hardboard

- Usually 3mm thick

- Not fully rigid

- Used to line damaged wood floors before carpeting

- Also available with a semi-gloss white finish

- Most popular as cupboard backs and drawer bottoms in cheap furniture

- Vulnerable to water damage

- Hardboard is occasionally called HDF (high density fibreboard), or masonite (a US trade name).

Pegboard

- Hardboard with a matrix of prepunched holes.

- Used for vending displays, long metal hooks go in the holes and products are hung on these.

- Can be used to hang hand tools, leads etc

Matchboard

Matchboard is thin tongue & grooved strip wood, and is sometimes mistaken for a sheet product when fitted. Picture here

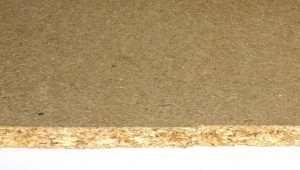

Chipboard

- aka Particleboard

- Low cost sheet material

- Made from wood chips & sawdust glued together.

- Very widely used

- Dimensionally stable, as long as kept dry

- Very vulnerable to water - some is ruined by a single wetting

- Much weaker than real wood

- Comes in differing strength & finish grades

- Occasionally called LDF, low density fibreboard

- Made from mostly recycled wood.

- Density 0.6-0.7 g/cc

Types of Chipboard

Low Density

- Weak

- A bit flaky

- Cheap

Flooring

- Aka high density

- Stronger

- Used for flooring, worktops & speaker cabinets

- Often tongue & grooved for improved alignment & smoke resistance

Moisture Resistant

- P5 grade

- often coloured green

- For bathroom floors

Veneered chipboard

Melamine

- Chipboard surfaced with plastic impregnated paper

- Tough fairly durable surface

- Easy to clean

- Available in white, brown wood patterns, and sometimes other plain colours

- Veneer is very prone to chipping when cut

- Veneer tends to chip over time, making it look tatty

- Veneer chipping is mostly unrepairable

- Veneered chipboard is the most popular furniture material today.

Wood Veneered

- The great majority of wood effect chipboard is melamine veneered

- Real wood veneered chipboard is also seen sometimes (also called "furniture board").

Blockboard

- Strips of assorted wood glued together, with a layer of veneer on each side

- Used for furniture panels

OSB

- Oriented strand board

- aka Sterling board or waferboard

- Similar properties to plywoods

- A cheaper alternative to ply

- Waterproof

- different grades available: OSB1, OSB2, OSB3. OSB3 is weatherproof, OSB1 isn't

- Some OSB contains biocidal zinc borate to prevent mould & bacterial growth.

- OSB vs ply OSB vs ply

MDF

- 'Medium Density Fibreboard'

- Fine wood fibres glued together

- Almost uniform, can be tooled in any direction

- Free from knots & other defects

- Vulnerable to water

- Often criticised for being an aesthetically inferior finish to real wood

- Made from wood, scrap wood, recycled paper, bamboo, forest thinnings & sawmill off-cuts

- Some concerns have been expressed about formaldehyde outgassing, which can possibly cause eye or lung irritation during working. But this is no more or less true than with chipboard or hardboard.

- Can delaminate if screws are driven into the ends

- Green MDF is moisture resistant

- Red MDF is fire retardant

- Density 0.68-0.83 g/cc

Timberboard

- aka pineboard

- Strips of pine glued side by side to make sheet wood

- Each strip is in alternating grain direction

- Eliminates most of the potential for warping & cupping

- Finished to furniture standard

- Used for pine furniture construction, shelves, etc

- Density around 0.5 g/cc

Plywood

- Sheets of wood veneer stacked & glued together

- Each sheet has grain laid at 90 degrees to its neighbours

- Excellent strength in both directions.

- Available in various grades: - Marine, WBP, fair faced, beech, underlay, etc

- Various thicknesses from 4mm to 2"

- Small sizes, such as 1/64" 1/32" & 1/16" ply are available from model shops

- Flexible 4mm ply also available

- Custom sizes may be made from veneers

- Not one of the cheaper sheet materials

- EN ratings

- Density 0.5-0.65 g/cc

Types of Ply

Marine

This is a very expensive and high quality product. It is made with waterproof resins that will withstand prolonged immersion in water. The board is also guaranteed to have no gaps or "voids" in it, with no knots in any of the laminations. It is strong, durable, won't de-laminate, and can be finished to a high standard.

Marine ply isn't generally used in buildings, but WBP is sometimes misdescribed as marine ply.

Weather & Boil Proof (WBP)

This is what most people usually mean when they say "marine ply". It was a high quality ply suitable for outdoor applications. As its name suggests it remained waterproof, and didn't blister or de-laminate even if soaked and then left to dry in the sun. Unlike marine ply it could have small voids, and was not suited to constant immersion, but was cheaper. Finish was usually nice and uniform (if a little plain) with no visible knots in the outer surfaces.

Note the past tense. WBP is no longer an accepted standard and sheet marked WBP does not now generally meet these standards. Delamination often happens when using it outdoors.

Shuttering ply

This is also WBP but it does not look as nice or "finished". This is because it is usually made from spiral cut laminations, and so has knots and other marks visible in all the laminations, and a slightly rough surface. Its intended use is for building shuttering to temporarily enclose poured concrete work. It is strong and waterproof, but quite a bit cheaper than standard finished WBP ply. Shuttering ply tends to be somewhat absorbent at first, and is hence harder to decorate. The grain and texture of the surface will also tend to show through any finish.

CDX

Interior grade of ply - Unlike WBP this will not take well to getting wet. A couple of exposures to moisture is usually all it takes to have the surface start to bubble, and the laminations start to come apart. It is cheaper than WBP and much better looking than shuttering ply, it will also decorate and finish well.

Fair faced

This is a whole category of veneered and finished plys suitable for furniture making. Strong and dimensionally stable, the outer layers of veneer are usually cut from a more attractive hardwood, that will look to all intents and purposes like a solid hardwood when assembled and finished. Depending on the veneer chosen, these can be expensive (although still cheaper than solid hardwood). Note that similar MDF cored products are also available.

Underlay

Underlay ply contains no voids, giving it maximum resistance to point loads.

Underlay ply is used to provide a tough gap-free surface for tiling, carpeting, lino etc, and to take up slight differences in floor height, eg where lino abuts carpet. It comes in sizes from 1/8" to 3/8".

Underlay ply is not waterproof. It should only be installed on completely dried floors. 2 days in its final location are recommended to acclimatize before laying.

Russian ply

Ply with thick birch faces, used for furniture.

Hatter's ply / Wigglewood

Flexible ply with the grain of all layers running in the same direction. Used for making curved furniture - and top hats.

Laminate

- There are different constructions of laminate flooring,

- Hardwood on chipboard, with or without a balancing underside layer of wood for greater stability, makes a good quality lamiante floor

- Lower quality laminates may just be printed hardboard

- Used for flooring

SIP

- Structural Insulated wood Panels

- 2x OSB outer layers with insulation fill.

Pinboard

- known as LDF, pinboard or Sundeala (brand name)

- soft fibrous board

- easy to push pins into it, used for noticeboards

- discussion & suppliers

Sheet plastics

Opaque sheet has high price & lacklustre performance for most DIY purposes. Translucence is usually what makes plastic sheet useful for DIY.

Acrylic

- Clear sheet used to replace glass

- Perspex is a well known trade name

- Tends to crack when cut or drilled

- Can be glued with acetone or acrylic dissolved in acetone

- Available in semi-flexible 2mm and rigid 4mm

Cutting methods:

- score on both sides & snap

- quick but sometimes goes wrong.

- Fine toothed saw

- less risk of breakage

- keep saw pressure always low

- Die grinder with cutting disc

- melts through the sheet

- won't crack the sheet

- occasionally necessary to recut any bits that re-fuse

- Angle grinder with thin grit cutting disc

- melts through

- keep pressure low

- cutting disc ends up a mess

- standard twist drill

- tends to crack the sheet

- best avoided

- mini grinding stone in die grinder

- melts its way through

- fast & safe

Polycarbonate

- One of the toughest plastics

- Clear or tinted

- Flat sheet, Twinwall & Triplewall available

- Multiwall sheets contain air spaces giving insulation

- mainly used as clear & tinted roofing sheet

- much higher price than acrylic

uPVC

- Used for cills, bargeboards, soffits, cladding

- White is the most popular colour

- Also used to line showers sometimes, but a poor substitute for ceramic tiles

Corrugated PVC

- Roofing sheet

- White, translucent or tinted

- Different corrugation sizes & shapes available

Sheet Metals

EML

- Expanded Metal Lath

- Sometimes loosely called 'gauze'

- Used to support and reinforce render & plaster

- Galvanised

- Stainless steel also available, at several times the price

Stainless Steel

- Extremely durable

- Used as a kitchen splashback

- SS sheet is too expensive for other uses in any significant amount

Rebar

- an open grid of steel bar

- for reinforcing concrete

- Cut with bolt croppers or angle grinder

- Available in 6mm to 16mm bar diameter

See also:

Lead

- Sheet lead is mainly used for joins, valleys etc in roofing

- Occasionally used as a very effective sound absorbing stud wall lining

- Lift lead rolls safely, back injury is a risk

Corrugated steel

- Very effective shed roofing material

- But rust makes it ugly

- All corrugated roofing is fixed at the peaks, not valleys

Composites

Composite roofing sheet

- Onduline, coroline etc

- corrugated roofing sheets

- made from cellulose fibres & bitumen

- fairly low strength

- need good support

- longer lasting than felt roofing

- Onduline is 3mm

- Coroline is 2.6mm

Asbestos

- Corrugated asbestos cement sheet

- No longer installed due to safety concerns

- Long lived

- Asbestos is still widespread in Britain's housing stock

- Rigid asbestos sheet can normally be made safe in situ

- DIY disposal of asbestos at home is legal if you follow some basic rules

Asbestos replacement

- Glass fibre reinforced cement sheet

- looks & behaves like asbestos sheet

- safe, in current use

- corrugated sheet used for roofs

- flat sheet used wherever a high strength thin flat sheet is required

- much longer lived than soft composite sheets

- not cheap

Other Sheet Materials

Plasterboard

- Most popular walling sheet

- Cheap

- Not as strong as wood sheets

- Cut with handsaw or knife

- 2 sheets of paper with gypsum inbetween

- 12mm for walls, more robust

- 9.5mm is lighter for ceilings

- Thinner flexible PB is used for curved surfaces

- Available with various edge profiles: square edge, taper, recessed

- 2 layers gives better soundproofing and longer fire resistance

- Smaller sheets eg 3x5 are used for ceilings due to the fairly heavy weight of 4x8 sheets

- More expensive specific use types also available:

- Foil coated board acts as a vapour barrier

- Fire protection boards have added glass fibre

- Soundproofing boards have lower sound transmission

Clayboard

- Used as plasterboard

- Typically 1" thick

- Construction as plasterboard, but using clay based plaster

- Much heavier than plasterboard

- Better sound absorption

- Not very popular

Fibre Cement

- New fibre cement sheet is glass fibre or cellulose fibre reinforced cement.

- Old fibre cement sheet (until 1986) was normally asbestos fibre reinforced

- Asbestos & fibreglass sheet have very similar properties, except for health issues with asbestos

- Weatherproof

- Robust

- Fairly fireproof

- Long lasting

- Glass fibre boards ruin drill bits & saw blades

- Not cheap

- Used for soffits, bargeboards, furniture, garages, bunkers, heatproofing, fireproofing, and sometimes found in place of plasterboard.

- Breakage on outbuildings is largely due to the very thin elements used.

- Old asbestos cutters are not suitable for use on new fibre cement sheet

Sag

Sag can be an issue with sheet materials, especially the lower strength ones like chipboard.

The Sagulator calculates short and long term sag, given the dimensions, loading and material type.

See Also

Insulation sheet materials

Wood Panel Industries Federation excellent guide to panel products